1. GENERAL

1.1 System description

The belt scale controller model H15 is equipped with all the basic belt scale controller functions such as: Flow

indication, Totalising, Status indications etc.

The H15 model designates all parameters basic default values during the start-up procedure.

This means that the controller will be ready to use immediately after a performed start-up procedure, without

putting in hours of endless programming and recording of parameter changes.

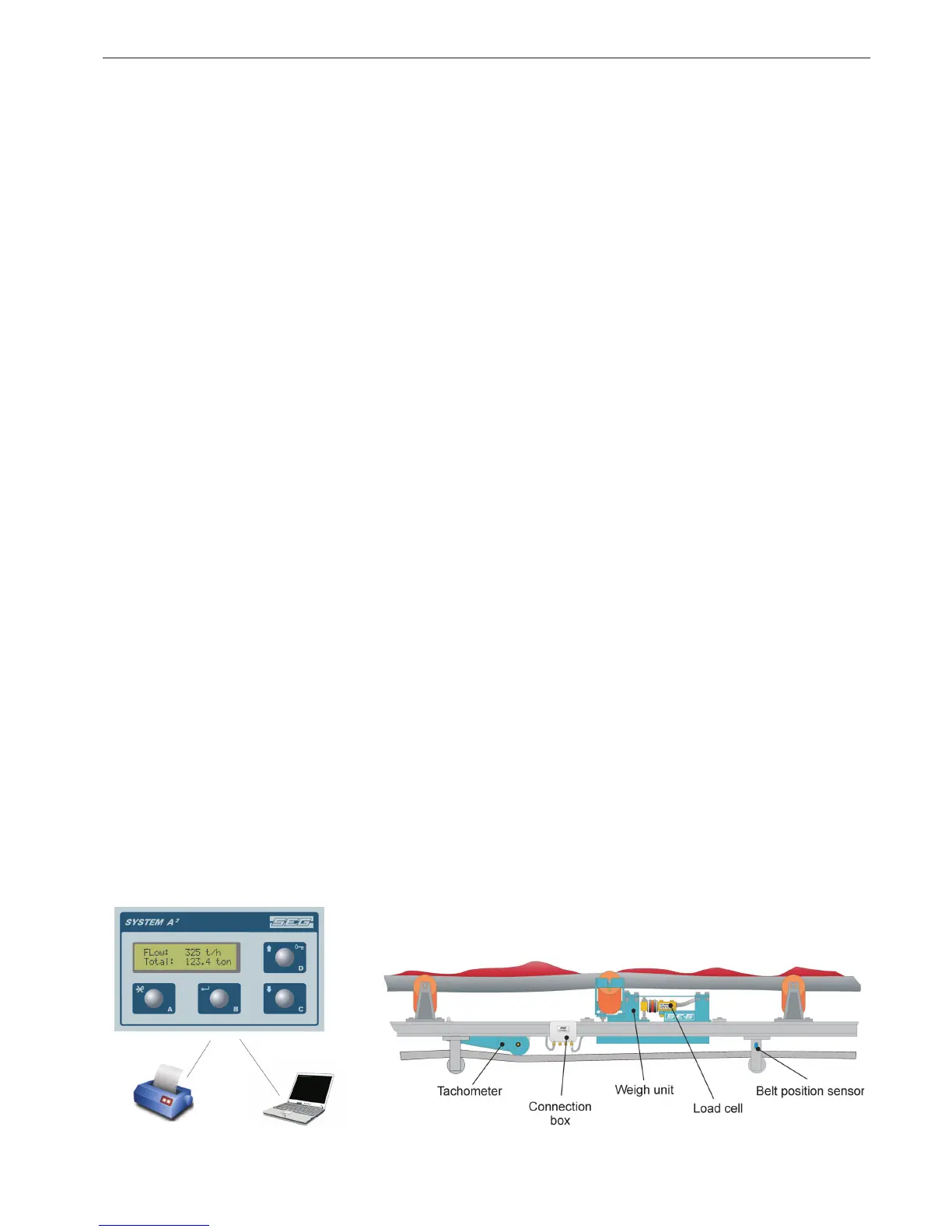

1.2 Belt scale parts

The belt scale's main components comprise devices for sensing the load of the material deposited on the belt,

measuring of belt travel, belt position sensor and the controller instrumentation.

Load measurement

This is performed with one or several weighing units installed in the conveyor.

The weighing unit built-in loadcell emits electrical signals proportional to the weight of material

per unit of belt length.

Weighing units are available for different capacities, belt widths and troughing angles.

The weighing unit supplied with each belt scale system is described in separate instructions.

Measuring of belt travel

This movement is measured with a single pulse sensor or a complete tachometer unit. The tachometer must be

brought to rotate at a rate which is proportional to the belt speed. The tachometer and its installation are

described in separate instructions. If an additional belt revolution sensor is connected, automatic belt

profiling compensation is possible. Influences of uneven belts and belt splices can then be almost completely

eliminated, resulting in a much higher totalising accuracy compared to standard belt scale controllers.

Instrumentation

The controller contains software program for processing of all measurement data from the weighing unit and the

tachometer. The controller is equipped with the following features/functions:

- Serial port RS485 with Modbus RTU, ASCII protocol for connection to a printer, PLC, PC etc..

- Built -in active 4-20mA output, galvanically isolated representing indicated flowrate.

- 2 output relays which can be designated different functions; totaliser pulse, flow level, etc.

The resulting processed data such as: Flowrate (t/h), Totalised amount of material, Beltspeed, etc.

Is accessed trough the built in LCD display unit, or remotely via serial communication.

Serial communication is useful for retrieving data intended for administrative purposes or process control. Data

can be transmitted/received in a number of different ways, such as: RS485 or via different optional fieldbus

converters like: Ethernet, TCP/IP, Profibus,etc.

18-08-16 S44-H15E 1-2

S-E-G SYSTEM A2-H15 INSTRUCTION

Loading...

Loading...