MANUAL DE INSTRUCCIONES CODIGO 80342 REV O 11/2021 Pag.: 35

J.P. SELECTA s.a.u. Autovía A-2 Km 585.1 Abrera 08630 (Barcelona) España Tel 34 937 700 877 Fax 34 937 702 362

e-mail: selecta@jpselecta.es - website: http://www.grupo-selecta.com

4. Introduction

The “STERIL-FOOD” autoclave has been designed to perform thermal treatments

of pasteurization or sterilization of containers (metal, glass, plastic) with food

content. The autoclave has the capacity to store 10 heat treatment programs

with 6 steps each.

All programs can be programmed by the user.

The autoclave works by spraying superheated water to transmit the heat (tem-

perature) on the containers subjected to heat treatment (except 20L model that

works by steam)

4.1 Temperature control

The autoclave uses two temperature probes:

•Watertemperatureprobe:

It indicates the water temperature of the autoclave. Located at the bottom of

the autoclave.

•Producttemperatureor“heart”probe:

Indicates the temperature of the product.

The F

0

value is calculated by the autoclave software from the temperature recorded

by the heart probe inserted in a container and the thermoresistance characteristics

of four types of microorganism according to the thermal treatment to which the

product is subjected:

In case of a sterilization process: Clostridium Botulinum; in case of pasteurization:

Bacillus coagulans, Streptococcus faecalis D or user denable.

The F

0

value is therefore subjected to time and temperature to which the products

are submitted during the respective thermal treatment (above 100ºC in sterilization

processes and above 67ºC and 55ºC respectively in pasteurization processes).

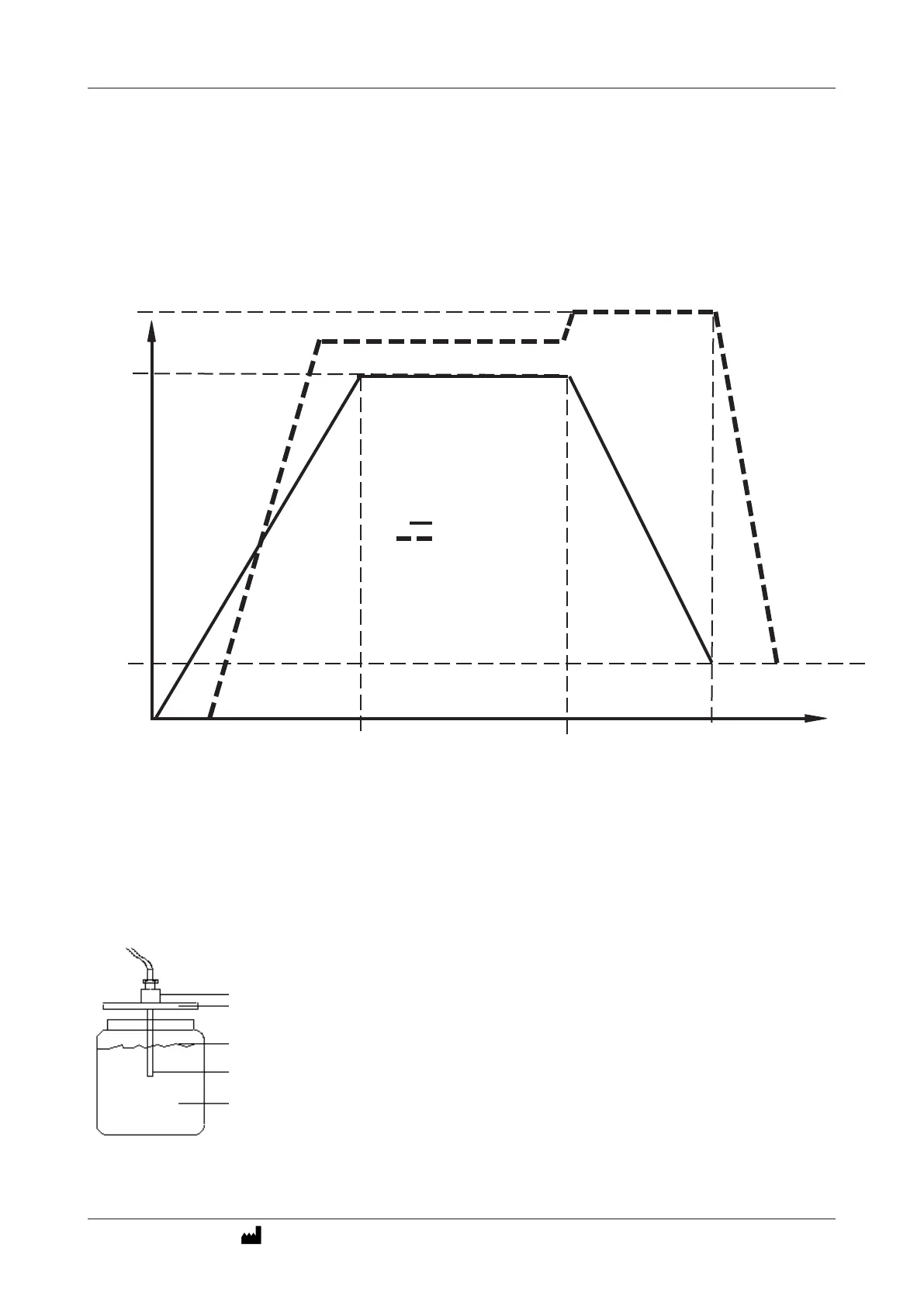

Product probe

also called «Heart probe»

cloSiNg pRobe

jaR lid

pRodUct

heaRt pRobe

caN

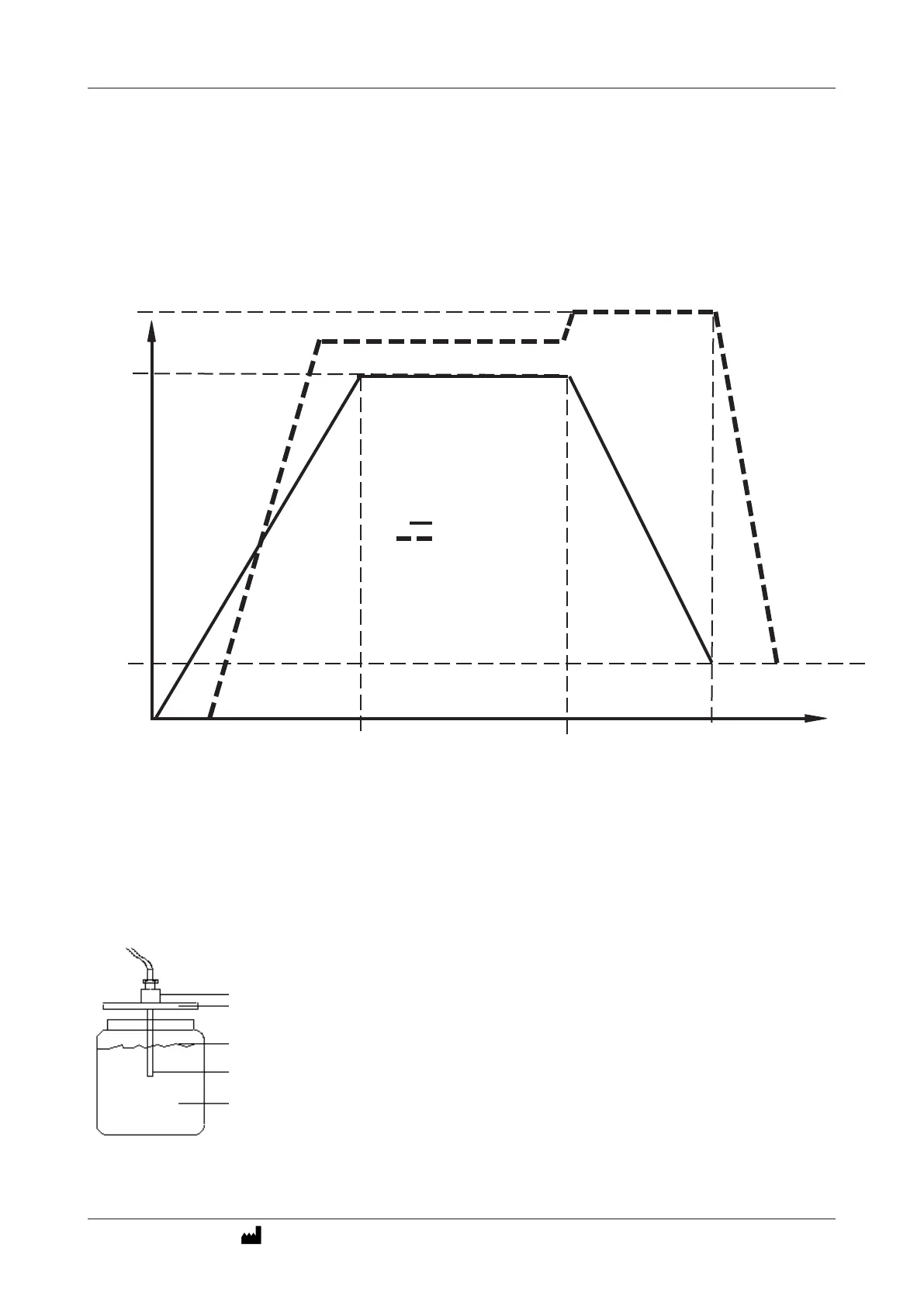

Fig 1. Temperature prole.

T

a

FINAL

T

a

Maintenance

P

Contrapressure

(bar)

(ºC)

(ºC)

(minutes)

HEATING MAINTENANCE COOLING DE-PRESSPRE-HEA-

TING-

Temperature

Pressure

Loading...

Loading...