Servicing

9.1 Inspection and maintenance

1FT7 synchronous motors

48 Operating Instructions, 04/2010, 610.40075.40b

9.1.2 Maintenance intervals

General information

Careful and regular maintenance, inspections, and overhauls are essential for detecting and

eliminating faults in good time before they can cause any consequential damage.

NOTICE

Inspection if there are faults or unusual conditions

Unusual conditions or faults that place undue electrical or mechanical stress on the three-

phase motor (e.g. overload, short-circuit, etc.) can cause consequential damage to the

machine.

If faults or any unusual conditions occur (e.g overload or short-circuit, etc.), the machine

must be inspected immediately.

Measures, inspection/maintenance intervals

Operating conditions and performance can vary widely. For this reason, only general

maintenance intervals for problem-free operation can be specified here.

● Maintenance intervals should therefore be scheduled to suit the on-site conditions

(fouling, switching frequency, load, etc.).

● Perform the following measures after the operation time or the interval specified in the

table below elapses.

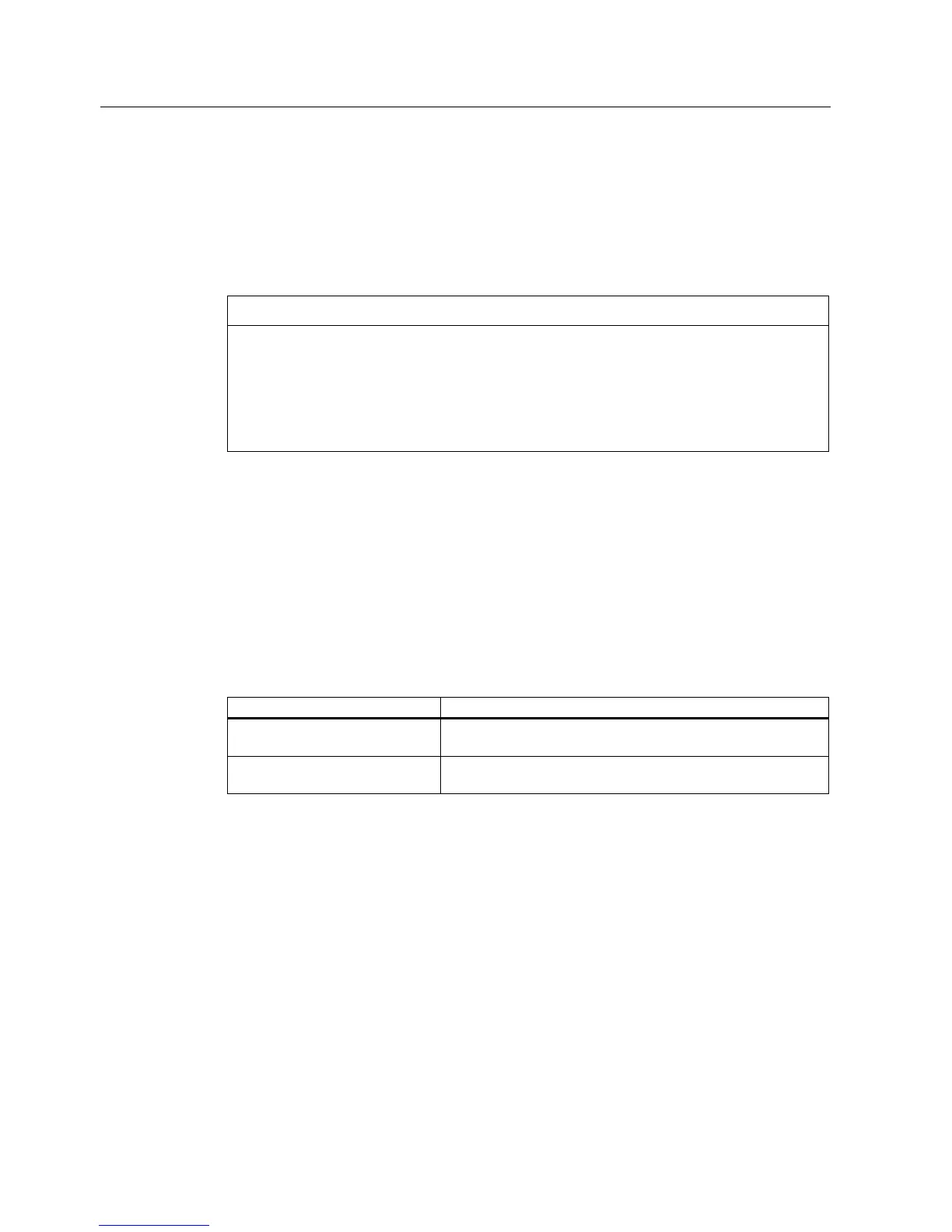

Table 9- 1 Measures after operation times or intervals

Measures Operation times and intervals

Replace the bearings After the recommended bearing replacement intervals (see the

chapter titled "Bearing replacement intervals")

Replace the radial shaft sealing

rings

Approximately every 10,000 operating hours with oil lubrication

Loading...

Loading...