22 / 62

BA 5060 EN 04/2011

2

1

3

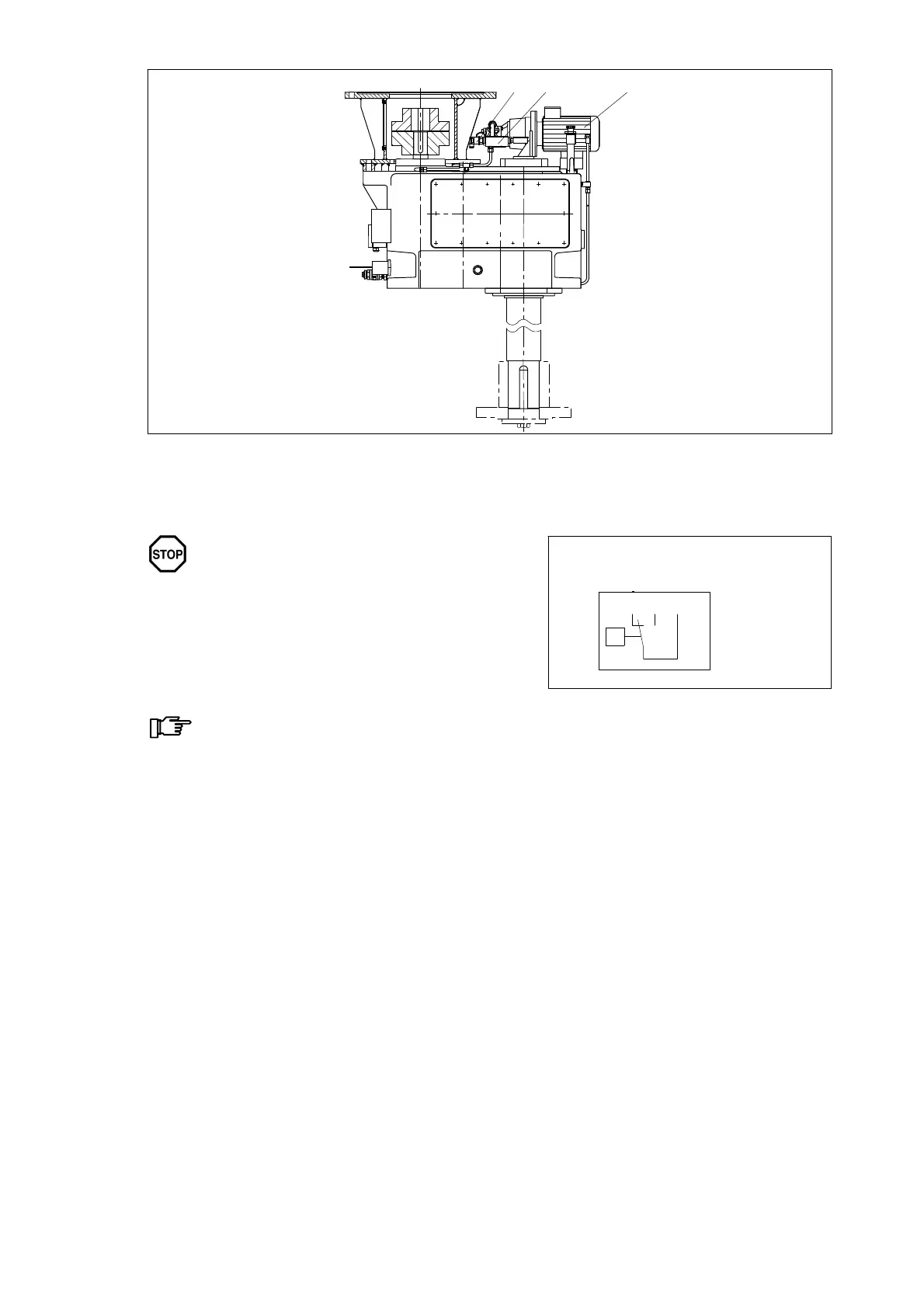

Fig. 7: Gearunit equipment with motor pump

1 Motor pump 2 Pressure monitor 3 Coarse filter

A detailed view of the gear unit can be obtained from the drawings in the gearunit documentation.

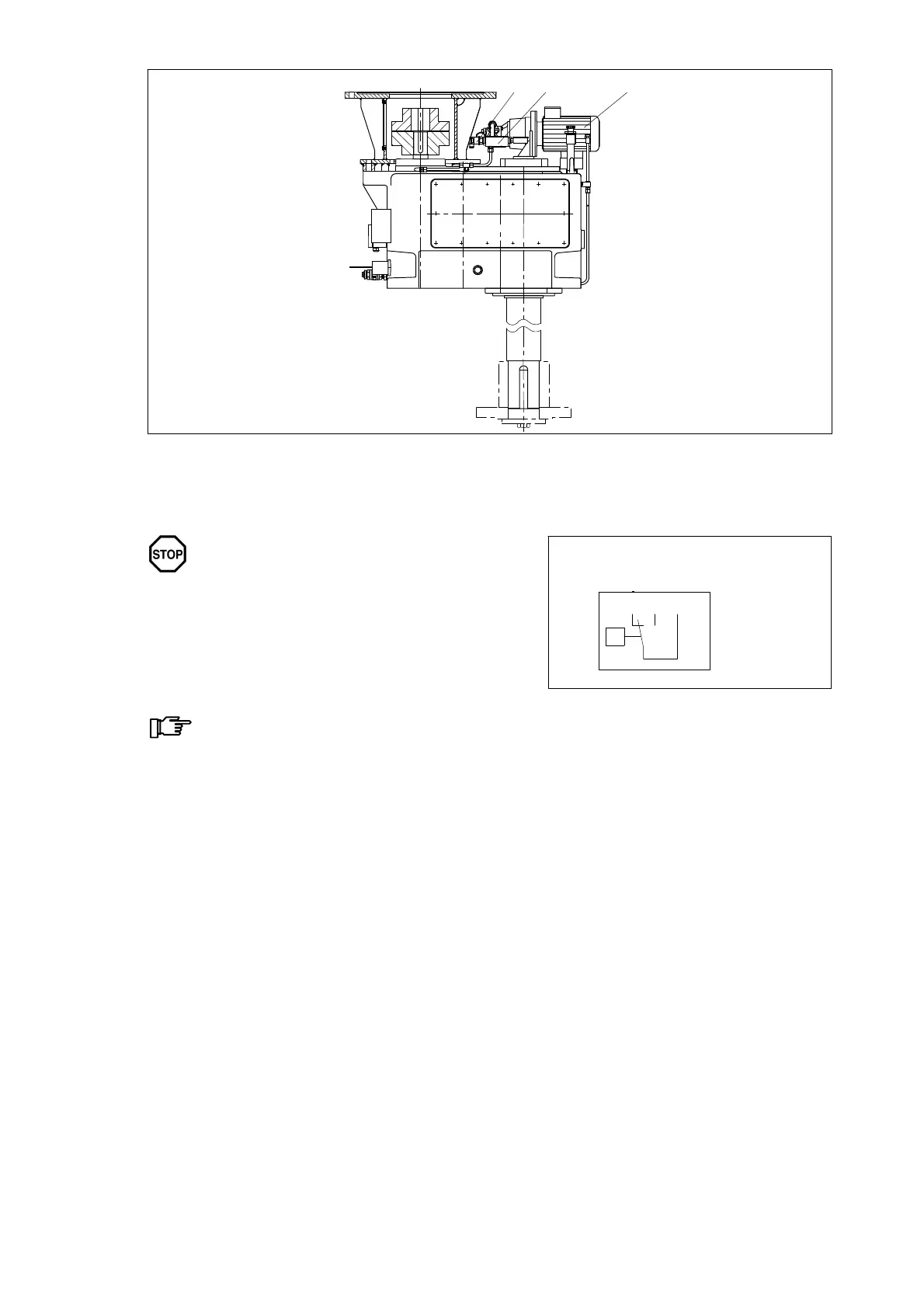

In case of gear units with a combined

splash and forced lubrication, it is

necessary to connect the pressure

monitor as an opening contact or closing

contact prior to startup.

The operation and maintenance of the pump, pressure monitor and coarse filter are described

in instructions included (where applicable) with the products.

For technical data, refer to the data sheet and/or the list of equipment.

5.4.1 Pump

The pumps used are suitable for the delivery of lubricants. The flow medium must not contain abrasive

components and must not chemically affect the materials of the pump. A precondition of a proper

functioning, high reliability and long service life of the pump is in particular a clean and lubrifying delivery

medium.

5.4.1.1 Filter

The filter protects downstream aggregates, measuring and control devices from contamination. The filter

comprises a housing with connections and a sieve. The medium flows through the housing where the dirt

particles flowing trough the pipe are retained.

Dirty filter elements must be cleaned or replaced.

5.5 Shaft bearings

All shafts are mounted in rolling bearings.

To be connected

as opening contact

or maker contact, a

required.

Oil pressure in accordance with

order-specific documentation

1

4

2PE

-S*

P

X

Loading...

Loading...