General Technical Specifications

6.5 Mechanical and Climatic Environmental Conditions

ET 200S Distributed I/O System - Fail-Safe Modules

58 Installation and Operating Manual, 08/2008, A5E00103686-07

Mechanical Environmental Conditions

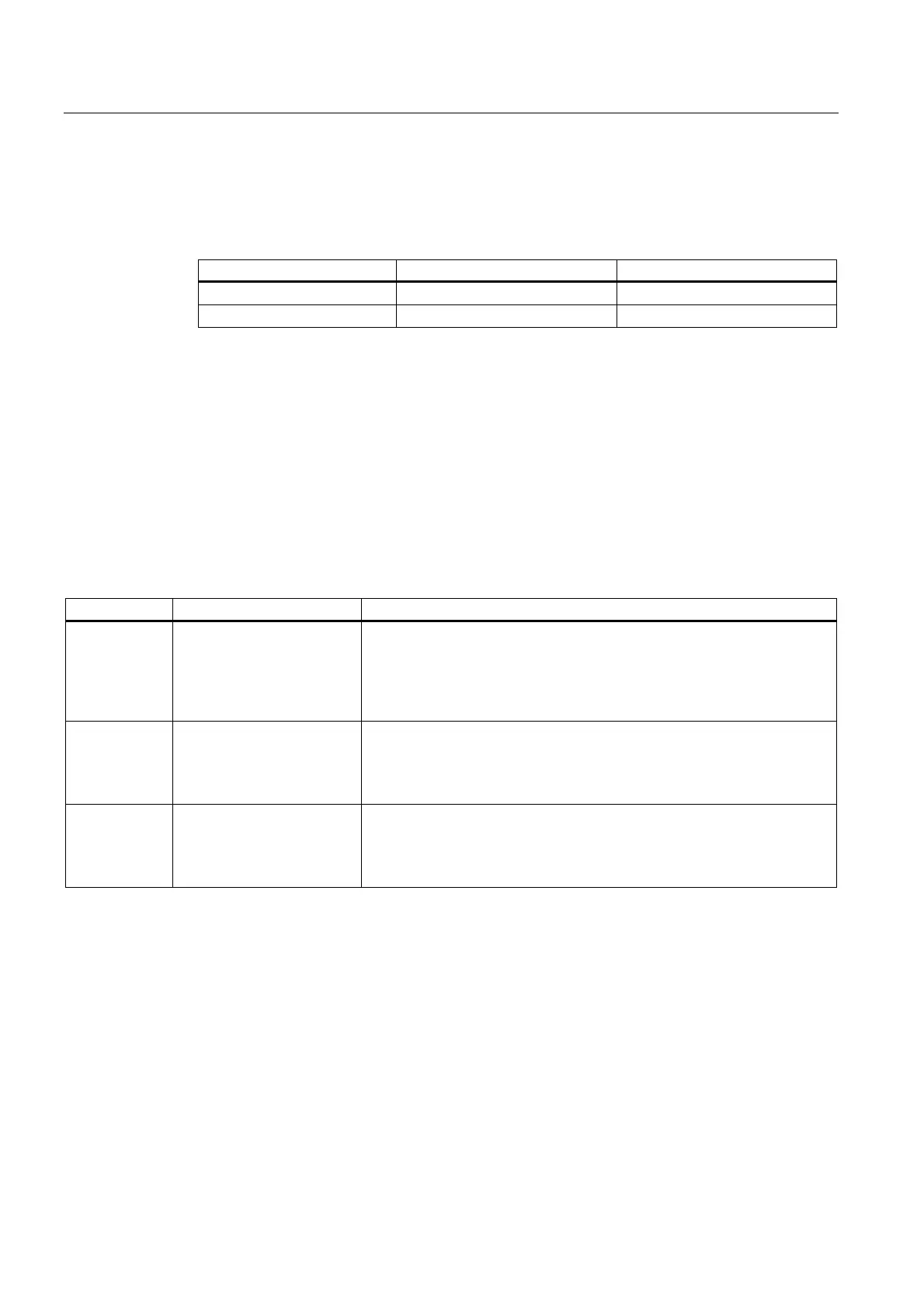

The table below shows the mechanical environmental conditions for F-modules in the form of

sinusoidal oscillations.

Frequency Range (Hz) Continuous Intermittent

10 ≤ f ≤ 58 Amplitude = 0.15 mm Amplitude = 0.35 mm

58 ≤ f ≤ 150 Constant acceleration = 2 g Constant acceleration = 5 g

Reduction of Vibration

If the F-modules are exposed to substantial shock or vibration, you must take appropriate

measures to reduce the acceleration and amplitude.

We recommend that you mount the ET 200S on damping material (for example, on a rubber-

metal vibration damper).

Testing of Mechanical Environmental Conditions

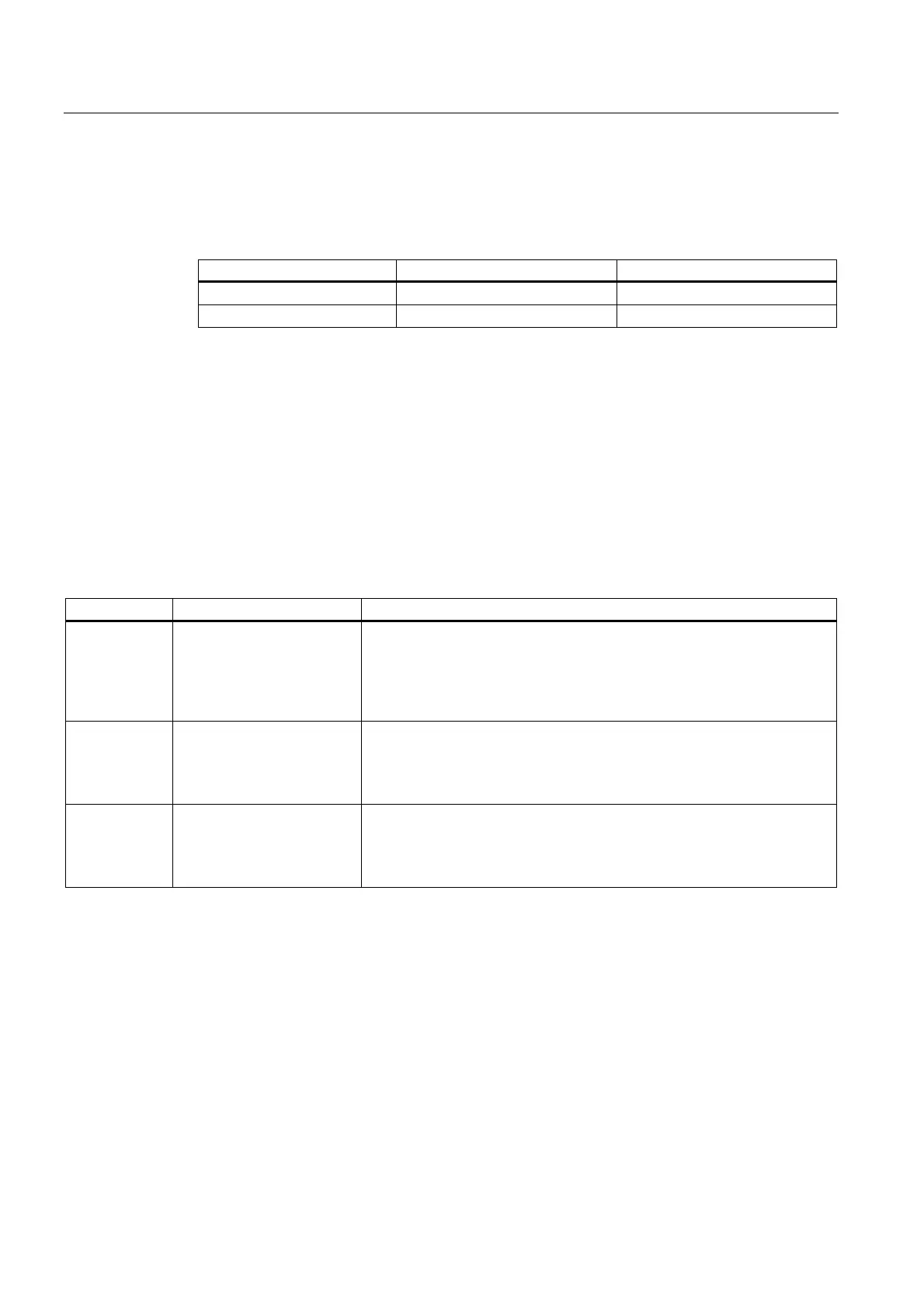

The table below provides information about the type and scope of testing of mechanical

environmental conditions.

Condition ... Test Standard Comments

Vibration Vibration test in accordance

with IEC 60068-2-6

(sinusoidal)

Type of vibration: Frequency cycles at a rate of change of 1 octave/minute.

10 Hz ≤ f ≤ 58 Hz, constant amplitude 0.35 mm

58 Hz ≤ f ≤ 150 Hz, constant acceleration 5 g

Duration of vibration: 10 frequency cycles per axis at each one of the three

perpendicular axes

Shock Shock, tested in accordance

with IEC 60068-2-27

Shock type: Half-sine

Shock severity: 15 g peak value, 11 ms duration

Direction of shock: 3 shocks in +/- direction at each of the three

perpendicular axes

Continuous

shock

Shock, tested in accordance

with IEC 60068-29

Shock type: Half-sine

Shock severity: 25 g peak value, 6 ms duration

Direction of shock: 1000 shocks in +/- direction at each of the three

perpendicular axes

Loading...

Loading...