5-15

Connecting TM I/O to PCS 7

C79000-G8076-C710-04

At every startup of PCS7/TM, the TPM 478-2 software performs an initiali-

zation and self-test routine.

LEDs 6-10 on the TPM 478-2 front panel provide information on operation

and startup behavior of I/O communication, thus enabling quick diagnostics

if an error occurs. The I/O startup behavior of TPM 478-2 is shown in Table

4-1 (sequence from left to right).

The table shows only some of the important phases. Depending on the PLC

software version and user structure, there are additional dark phases. In every

situation only the RUN LED is lit after startup of the I/O bus system (cyclic

operation).

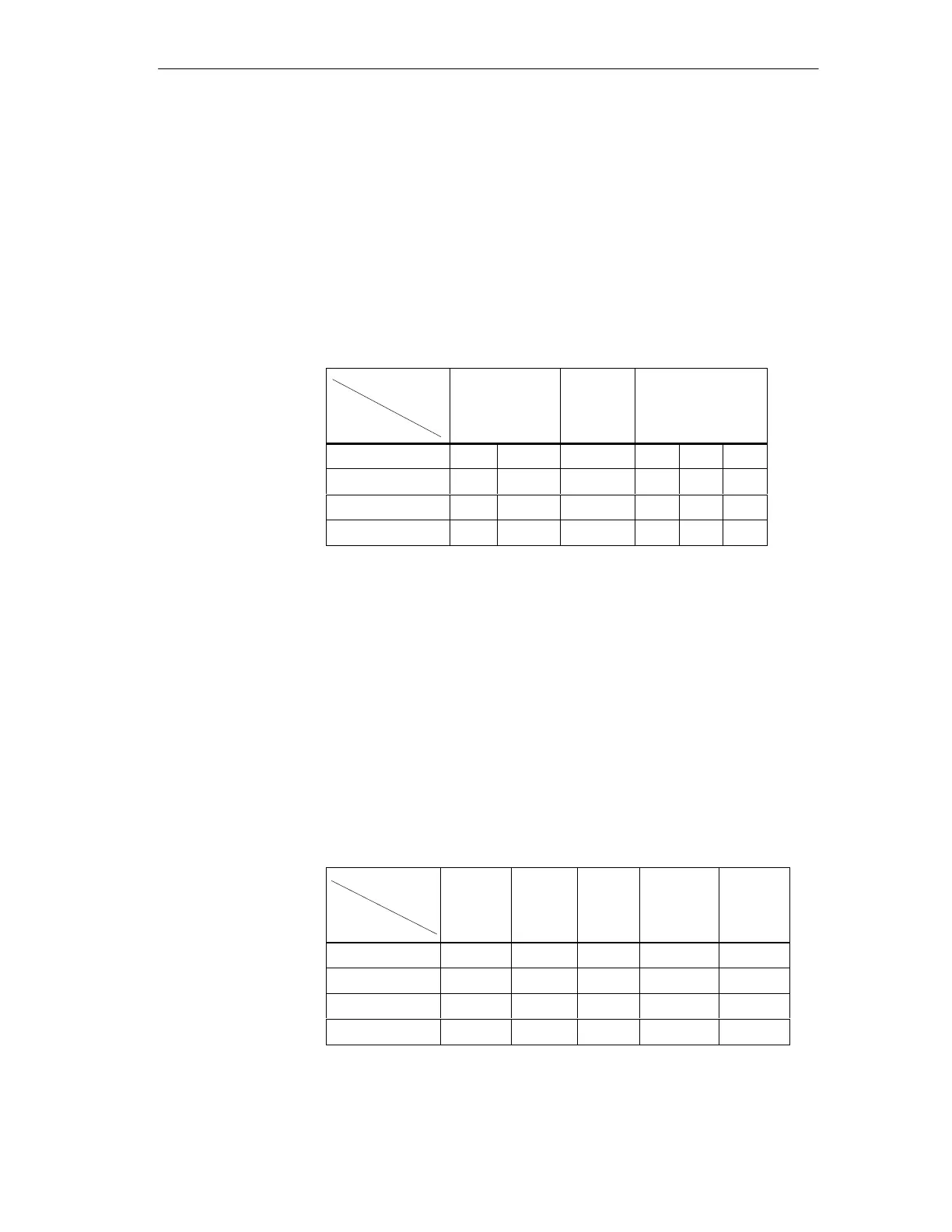

Table 5-1

Meaning

Display

Coordination Initializa-

tion/Self-

test

I/O bus system star-

tup

EIO (red) 0 0 0 0 0 0

PQA (yellow) 0 x x 0 x 0

PQB (yellow) 0 0 x x x 0

RUN (green) 0 0 0 0 x x

0 ¢ LED is OFF

x ¢ LED is ON

The fast coordination phase is hardly perceptible.

After a successful init/self-test phase, TPM 478-2 performs the startup of the

I/O bus system.

If an error is detected, TPM 478-2 interrupts startup and goes into STOP (red

LED EIO is lit). TPM 478-2 is defective if it stays in STOP state even after

several reset operations. When you return a defective module to the Electro-

nics Plant in Karlsruhe (EWK), Germany, specify which error displays have

occurred. See Table 5-2.

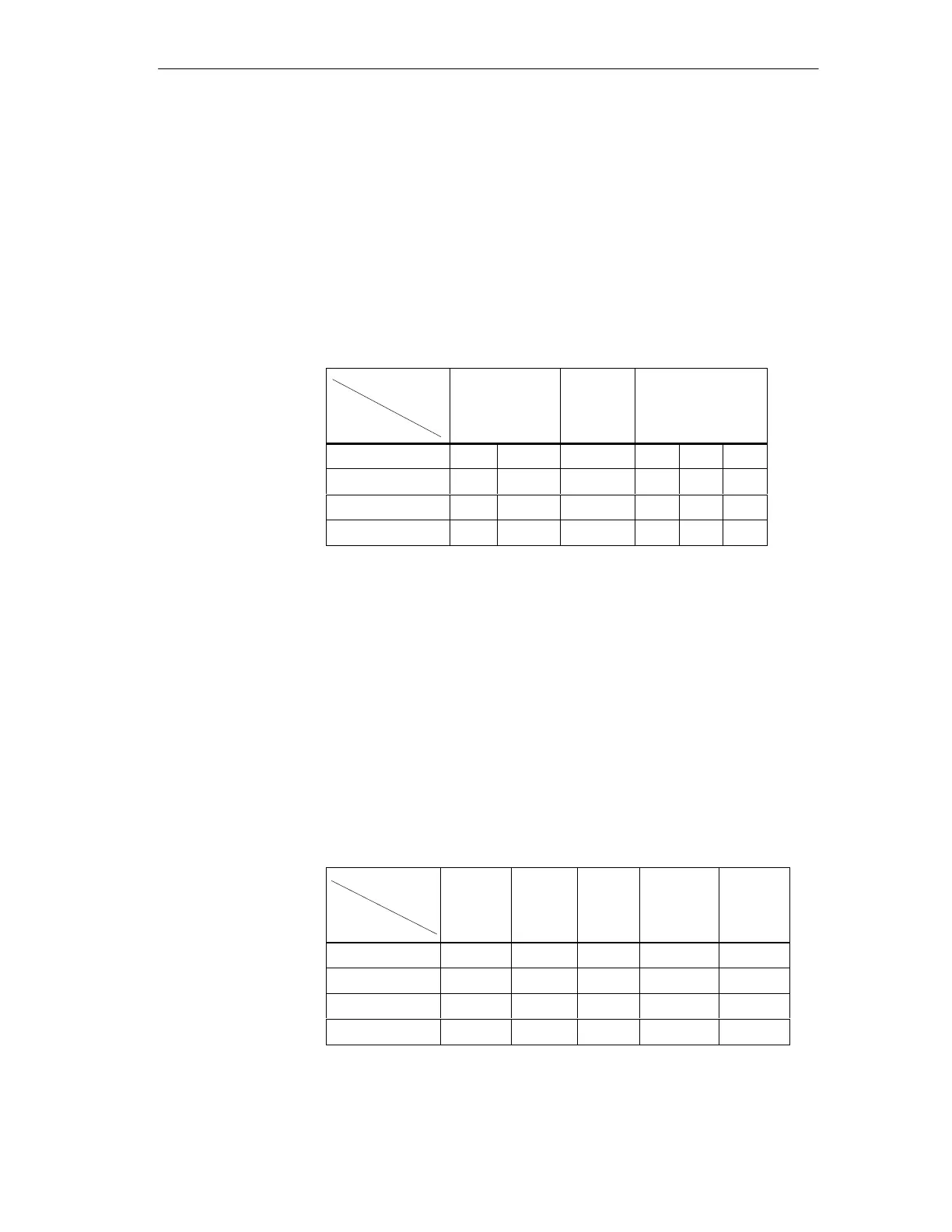

Table 5-2 Error displays on startup

Meaning

Display

Error in

local

RAM

DPRAM

error

Address

bus er-

ror

Program

memory

error

Watch-

dog error

EIO (red) x x x x x

PQA (yellow) x 0 x 0 x

PQB (yellow) 0 x x 0 x

RUN (green) 0 0 0 0 x

0 ¢ LED is ON

x ¢ LED is OFF

TPM 478-2:

Diagnostics of

I/O communication

Coordination

Initialization/

Selftest

Interface module TPM 478-2

Loading...

Loading...