Safety Programming Guideline

Entry ID: 109750255, V1.0, 10/2017

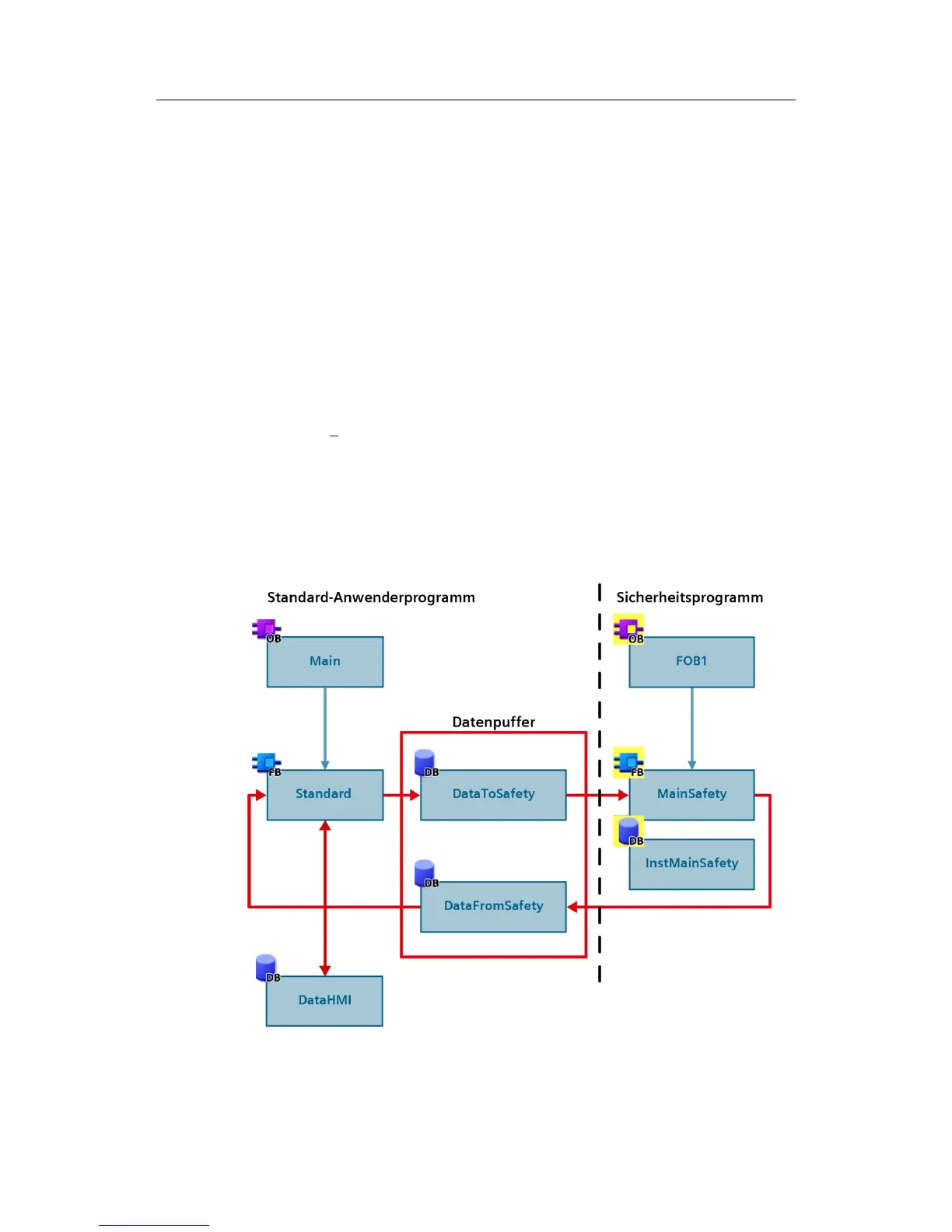

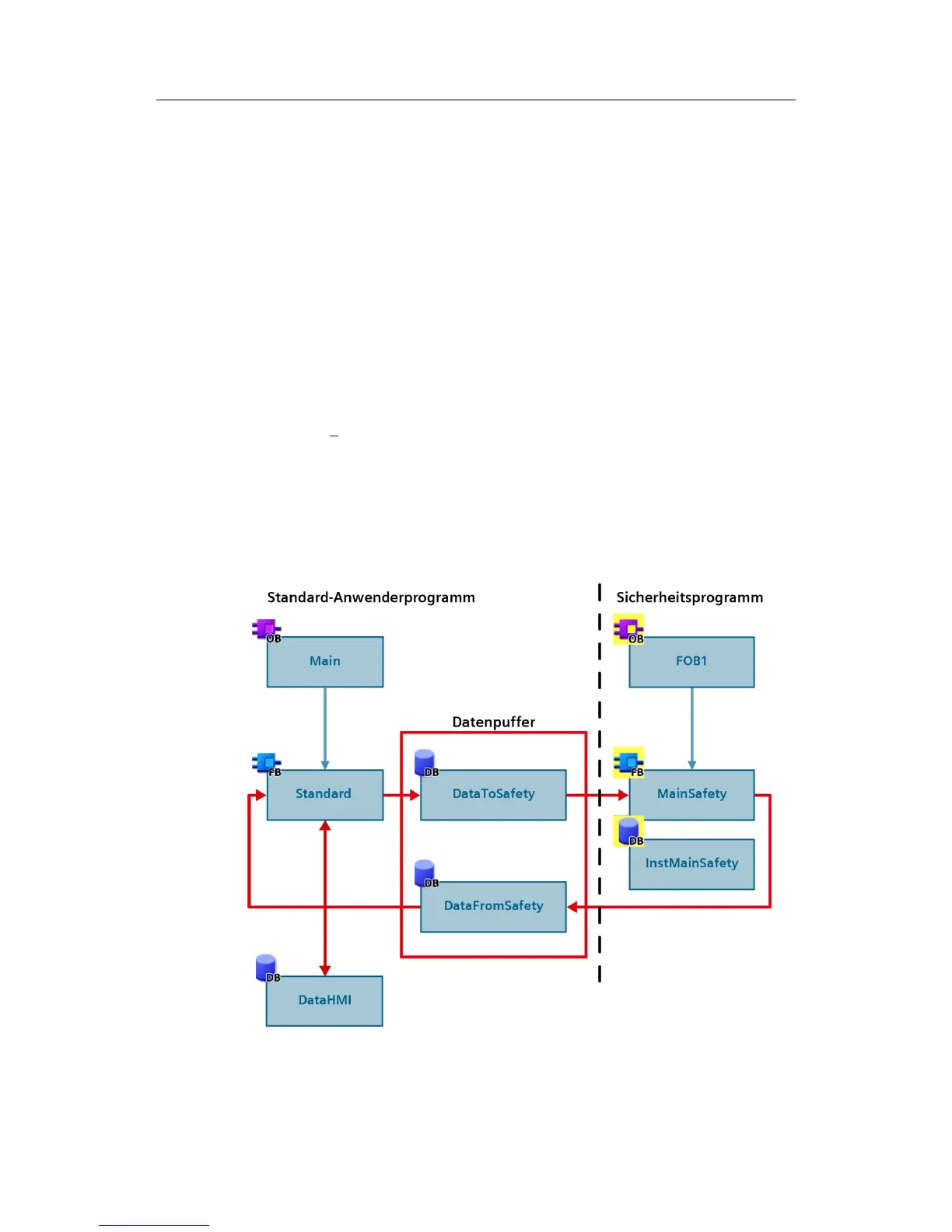

3.9.4 Transferring HMI signals to the safety program

Human-machine interfaces (HMIs) are convenient, essential components in a

machine operator's daily work. In order to use this convenience for operator control

and monitoring of processes and plants even in safety-related applications,

additional measures are required.

Writing tags from the HMI to the safety program is a problem for the following

reasons:

Signals from the HMI panel are not safety-related and not monitored. An error

can result in forbidden changes of safety-related values, which increases the

risk.

Communication between the HMI and the CPU is acyclic. As a result, the

HMI's write access may take place while processing the safety program.

The first program run then still uses the original value. The encoded user

program uses the value that has been updated in the meantime. This causes

data corruption in the safety program and therefore a stop of the CPU (see

Chapter 5).

Recommendation

Use another data block for communication with the HMI and copy the safety-

related data in the standard user program to the data buffer.

Figure 3-12: Data exchange between HMI and safety program

Loading...

Loading...