2

2.2 Electrical system requirements

2-38

E Siemens AG 2013 All Rights Reserved

SIMODRIVE POSMO A User Manual (POS1) – 08/2013 Edition

If multiple axes are braked simultaneously in a system for operational

reasons, e.g. in the event of an EMERGENCY STOP or quasi–simulta-

neous traversing, a power management module (DC PMM) must be

used in order to convert the regenerative feedback energy.

The DC PMM is connected between the load power supply and the first

positioning motor SIMODRIVE POSMO A.

Type Order No. (MLFB)

DC–PMM/24V 9AL2137–1AA00–1AA0

DC–PMM/48V 9AL2137–1BA00–1AA0

Note:

Operating Instructions in German and English

are provided with the power management

module (DC PMM).

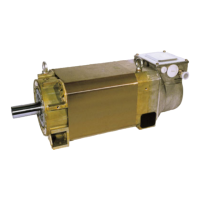

Fig. 2-9 Power Management Module (DC–PMM)

Functions, features and technical data:

S Converting the regenerative feedback energy using an integrated

pulsed resistor with i

2

t monitoring

S Regenerative feedback protection

S Signals (e.g. ready, fault)

S Max. continuous motoring current capacity: 25 A

S Ambient temperature: 0...55 _C

S Continuous power: 10 W (DC–PMM/24V)

15 W (DC–PMM/48V)

S Maximum energy drawn: 40 Ws

Example for POSMO A – 300 W (for 75 W, then P

D

= 10 W):

For power ratings above 15 W, the components, that are above

15 W are integrated up according to the following algorithm and may

not exceed 40 Ws.

V

s

2

P

t

dt –

∫

0

T

P

D

dt E

max

= 40 Ws

∫

0

T

– Transistor on:

P

t

=

R

PMM

=

(58.5 V)

2

2 Ω

= 1711.125 W; P

D

= 15 W

Vs = switching threshold PMM 58.1...58.5 V; R

PMM

= 2 Ω

P

t

– P

D

= 1711.125 W – 15 W = 1696.125 W

⇒ increment = 1696.125 W t

– Transistor off:

P

t

= 0; P

D

= 15 W

P

t

– P

D

= – 15 W

⇒ decrement = 15 W t

Power

Management

Module

(DC PMM)

2 Installing and Connecting–Up

02.9908.0306.05

Loading...

Loading...