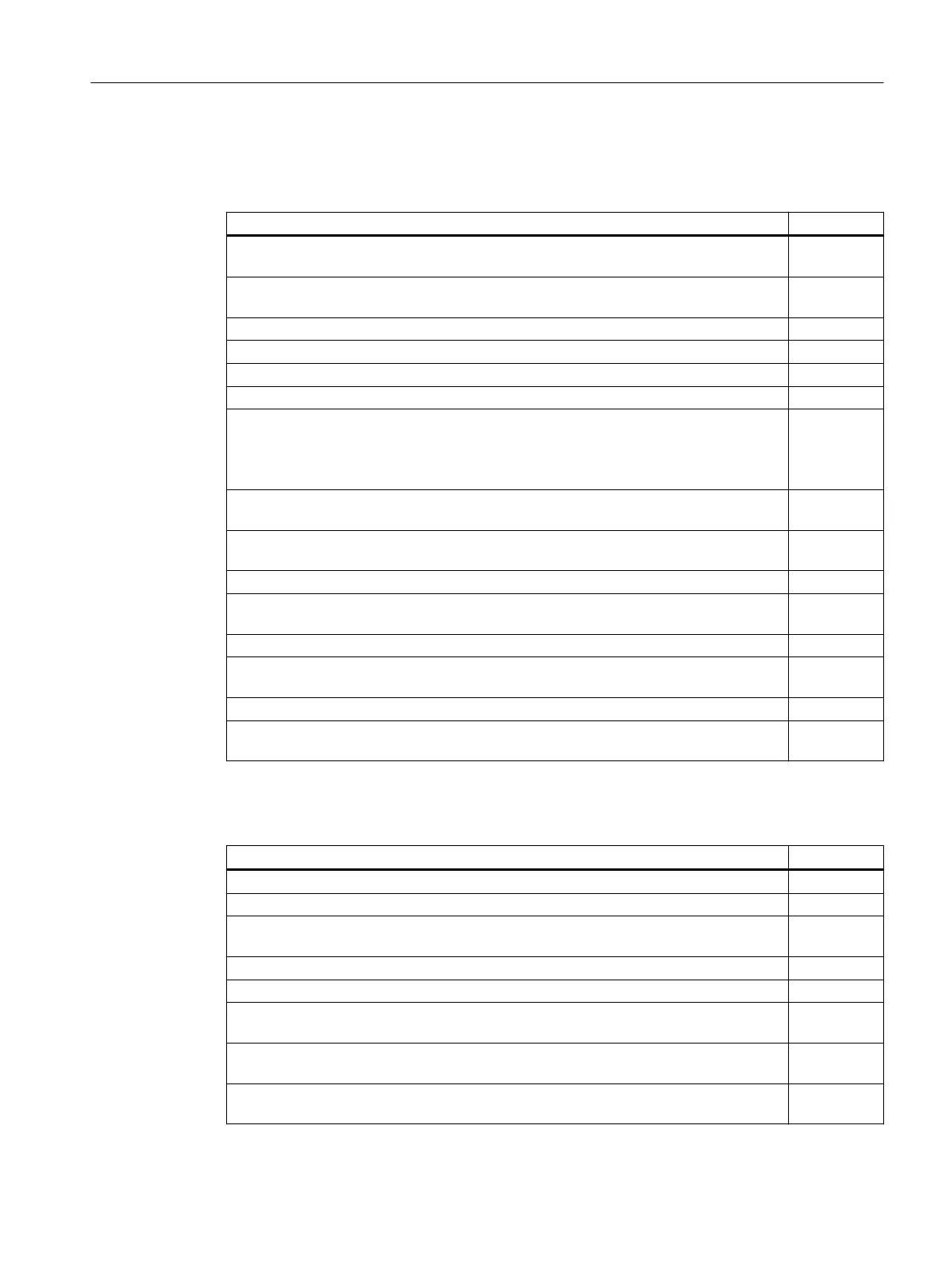

Table 7-2 Checklist (2) - checks regarding the mechanical system

Check OK

Is the motor already correctly mounted according to the motor manufacturer's data and

ready to be powered up?

Were the transport locks removed according to Chapter "Installation" in these operating

instructions?

Is the axis free to move over the complete speed range?

Have all the screws been tightened to the specied torque?

Have the stator and rotor been centered according to the motor manufacturer's data?

If a motor holding brake is being used, is this functioning correctly?

Has the encoder been correctly mounted and adjusted according to the manufacturer's

data?

Important information on the encoder is also provided in the Conguration Manual "SI‐

MOTICS T-1FW6 built-in torque motors".

Has the cooling system required for a liquid-cooled motor been connected according to

the manufacturer's data, and is it functioning correctly.

Does the coolant meet the requirements specied in Chapter "Coolant" in the Congura‐

tion Manual "SIMOTICS T-1FW6 Built-In Torque Motors"?

Were the cooling circuits purged before being lled with coolant?

Is it ensured that the permissible cooling circuit pressure stated in chapter "Technical

features" in the operating instructions will not be exceeded?

Are moving cables correctly routed in a tow chain?

Have the power cables been properly connected to the component terminals with the

specied torque?

Have measures been taken to relieve strain on the cables?

Have all installation devices and tools been removed?

Have you removed the spacer lm from the air gap?

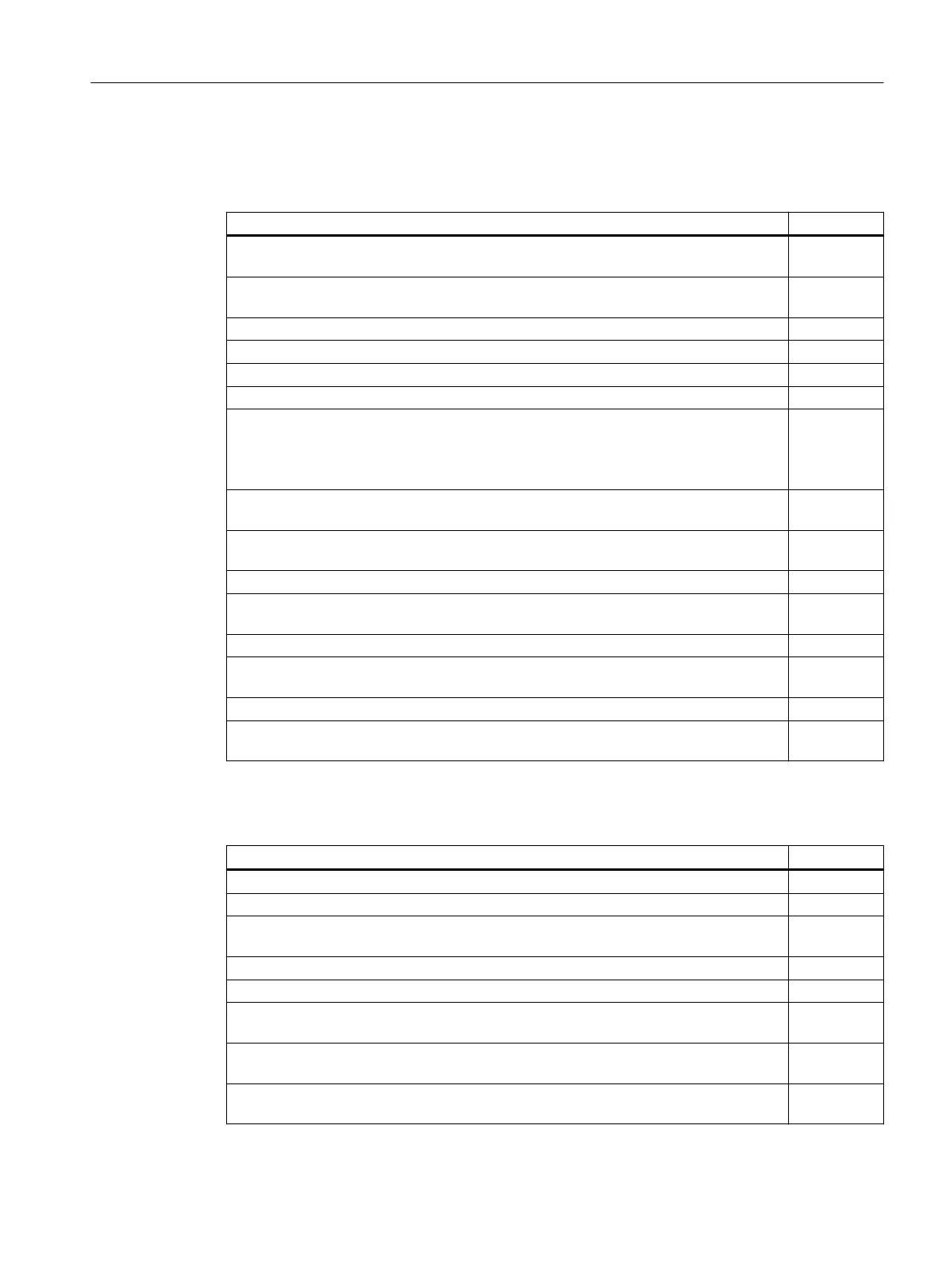

Table 7-3 Checklist (3) - checks regarding the electrical system

Check OK

Has all wiring work been successfully completed?

Is the protective conductor correctly connected?

Is the ground for the motors directly connected to the ground for the power modules

(short distance to avoid high discharge currents)?

Are all connectors correctly plugged in and screwed in place?

Are the motors connected with shielded power cables?

Are the power cable shields connected as closely as possible to the terminal box through

the widest possible surface area?

Are all cable shields connected to the respective housings through the largest possible

surface area?

Have the control cables been connected in accordance with the required interface con‐

guration and the shield applied?

Commissioning

7.2Checklists

1FW6 built-in torque motors

Operating Instructions, 09/2022, A5E52220812B AA 115

Loading...

Loading...