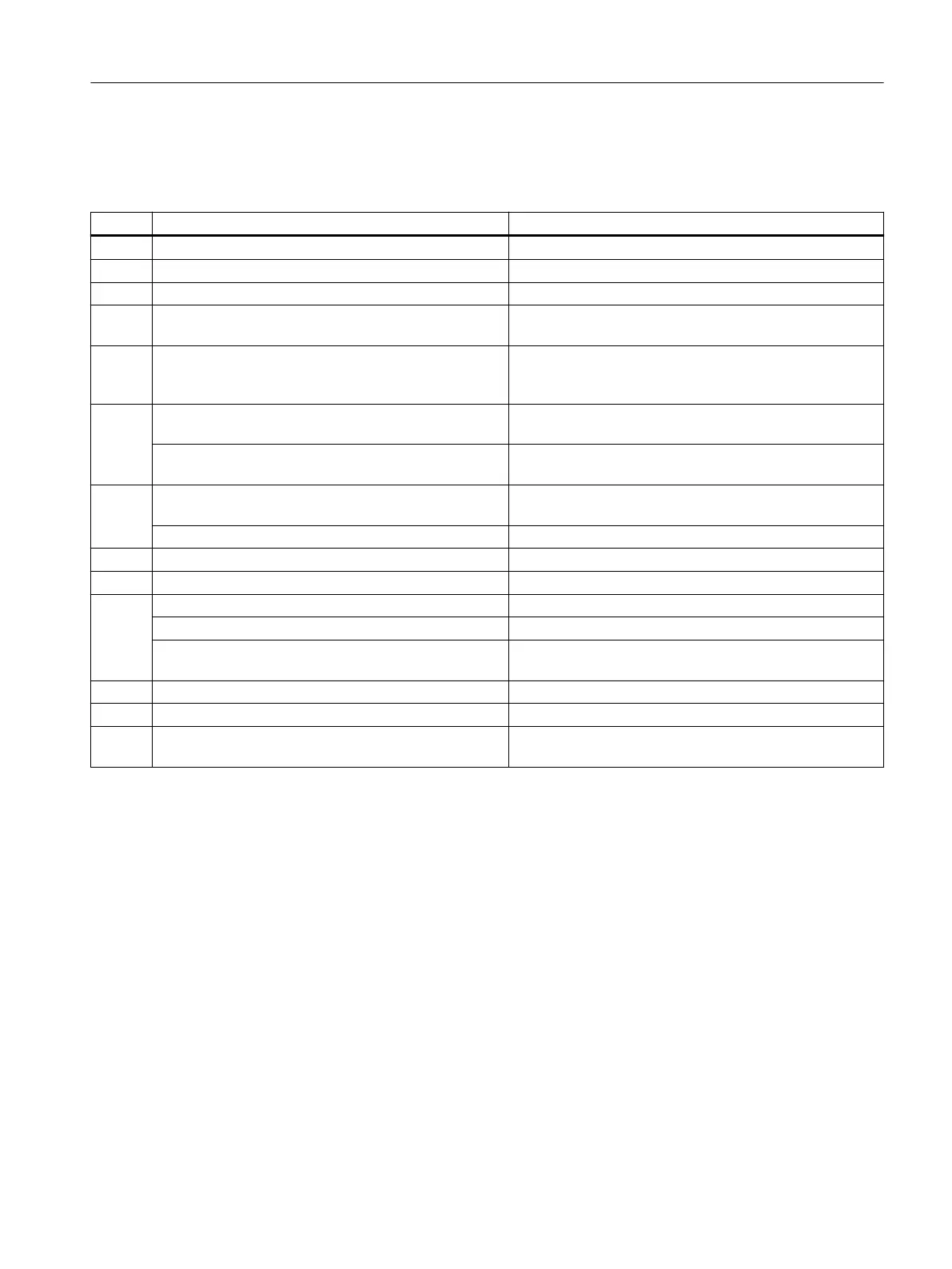

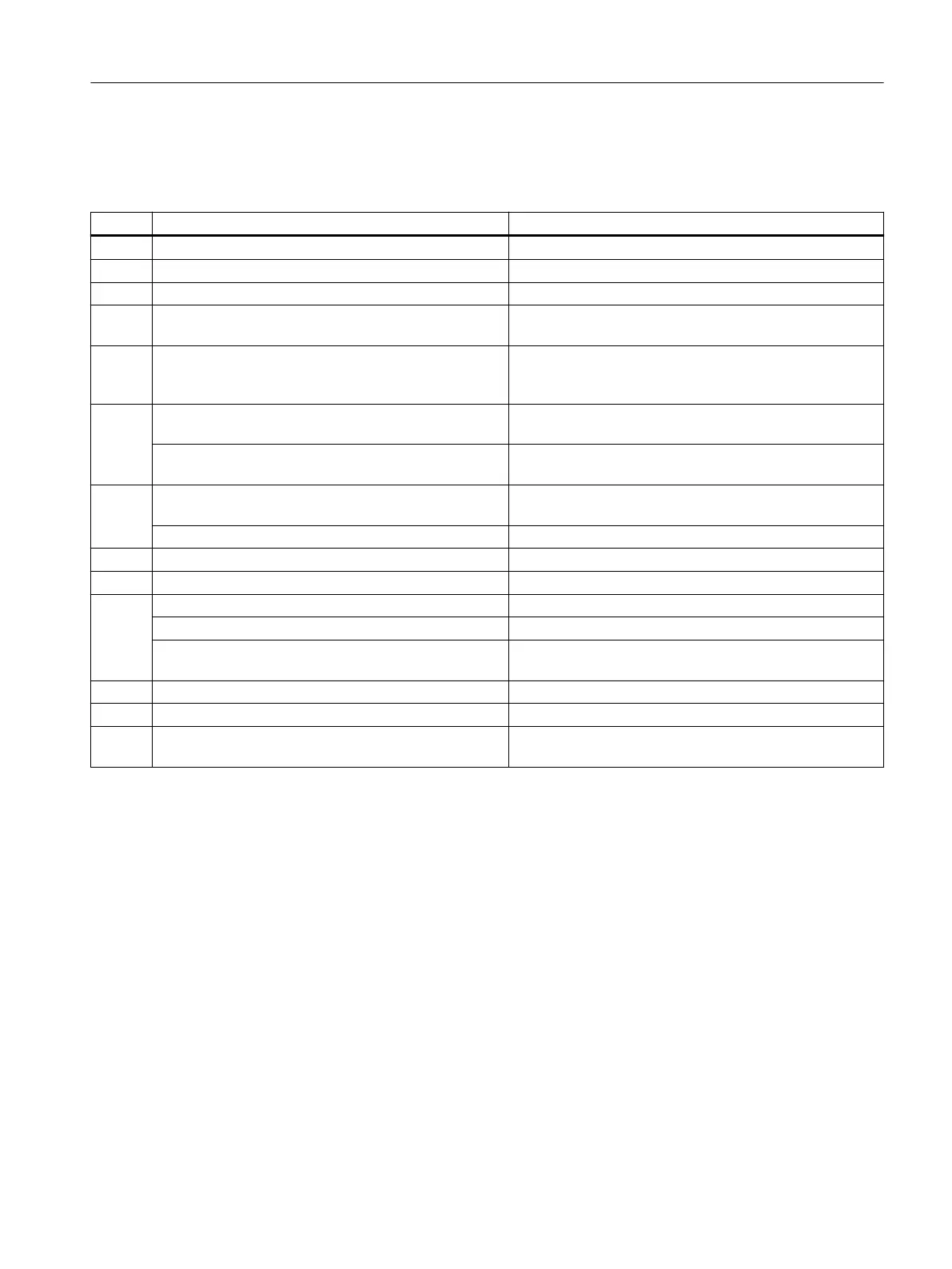

Table 8-2 Key to causes of faults and remedial measures

No. Cause of fault How to remedy the problem

A Overloading Reduce load

B Interrupted phase in the supply cable Check frequency converter and supply cables

C Interrupted phase in the supply cable after switching on Check frequency converter and supply cables

D Motor commutation is faulty Check the commutation, if required re-adjust the commu‐

tation angle oset

E Winding short circuit or phase short circuit in stator

winding

Measure the winding resistances and insulation resistan‐

ces, motor replacement after consultation with the manu‐

facturer

F Cooling water not connected / switched o Check cooling water connection / switch on cooling water /

check cooler

Water connection / pipes defective Locate leaks and seal as necessary, or consult the manu‐

facturer

G Cooling water ow rate too low Check cooling water ow rate according to data sheet

specication

Intake temperature too high Set correct intake temperature

H Insucient shielding for motor and/or encoder cable Check the shielding and grounding

J Drive controller gain too high Adjust the controller

K Rotating parts grind Determine cause and adjust parts

Foreign bodies in the motor Consult the manufacturer

Bearing damage Contact the manufacturer; where required, repair by the

manufacturer

L Poor alignment Align motor unit, check coupling

M Shocks from coupled machine Check coupled machine

N Cooling water pipes/water connection defective Locate leaks and seal as necessary, or consult the manu‐

facturer

If the fault still cannot be resolved after applying the measures specied above, then contact

Technical Support or your responsible sales partner.

Operation

8.3Dealing with faults

1FW6 built-in torque motors

Operating Instructions, 09/2022, A5E52220812B AA 121

Loading...

Loading...