• To secure the screws, choose long clamping lengths l

k

, l

k

/d>5 if possible; alternatively (if

l

k

/ d > 5 is not possible), check pretensioning of the screws at regular intervals (tighten with

calibrated torque wrench).

• Note the tightening torques specied in the table below.

• As a minimum, tighten the screws angle-controlled using a calibrated torque wrench with

the shortest possible bit insert; always tighten in diagonally opposite (180°) pairs.

You can increase the load capability of screw connections by employing an angle of rotation

or yield strength controlled tightening technique.

• Tighten all the screws to minimize the risk of them penetrating other materials.

Explanations:

I

k

= Clamping length of the screw in mm

d = Nominal diameter of the screw in mm (e.g. M8 screw: d = 8 mm)

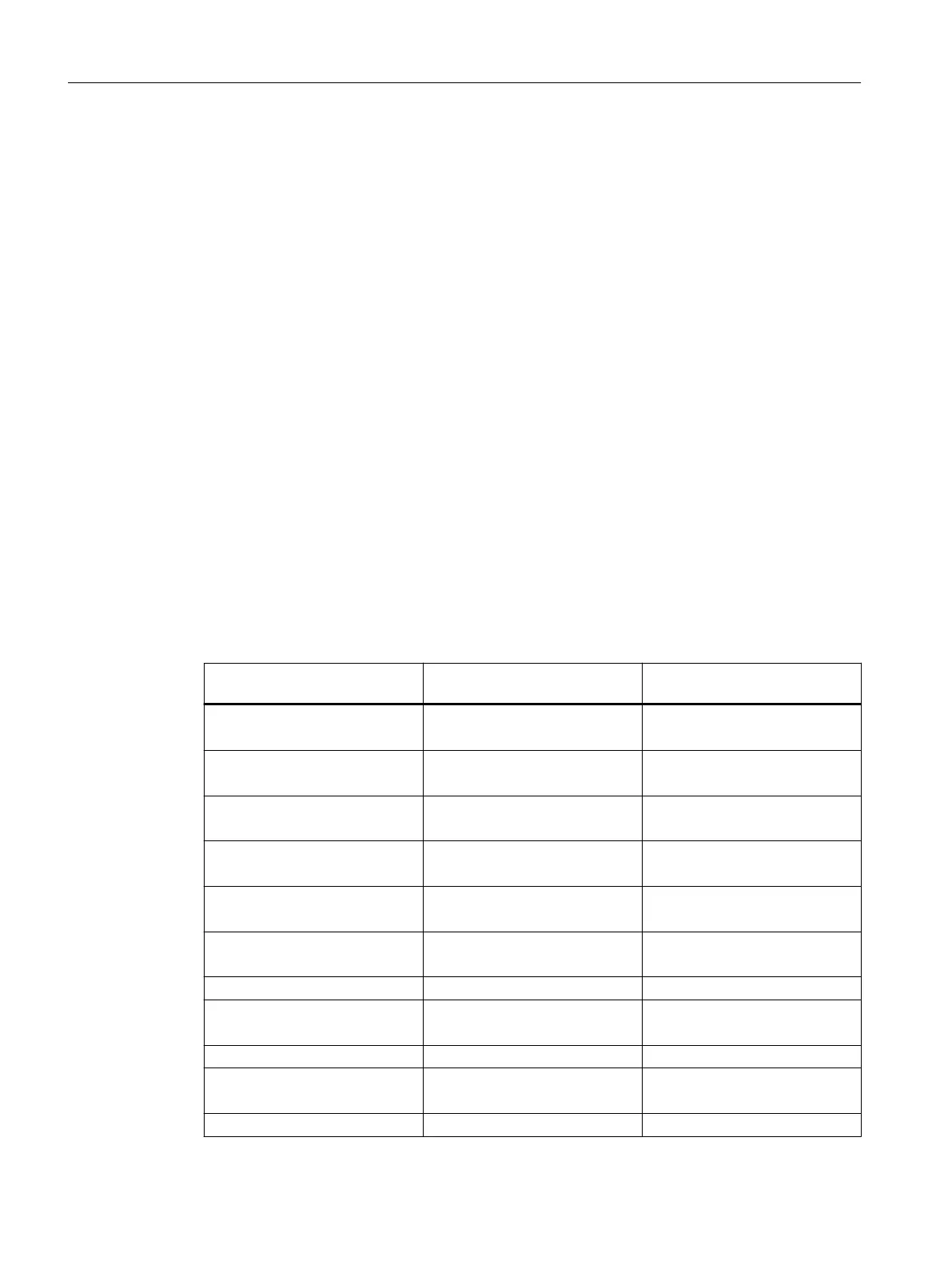

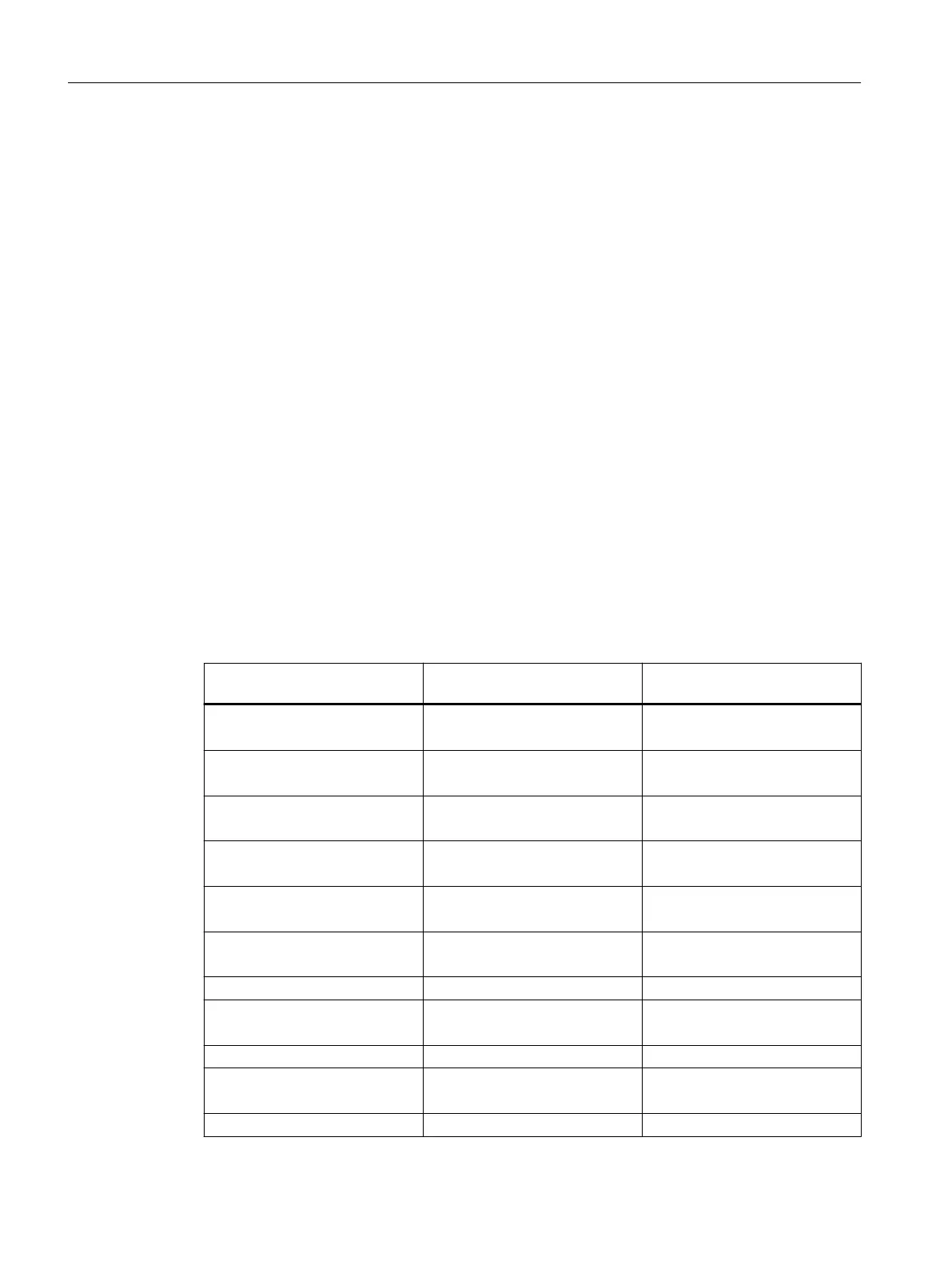

Screw material and tightening torques

Screws of varying strength classes are required to secure the motor to the machine structure.

The table below shows the required strength classes and tightening torques for the stator and

rotor xing screws.

Table 5-4 Required strength classes and tightening torques for the stator and rotor

Motor Screw

(strength class)

Tightening torque

M

A

in Nm

1FW6050-xxB03-xxxx to

1FW6050-xxB15-xxxx

M6 (8.8) 9

1FW6060-xxB03-xxxx to

1FW6060-xxB15-xxxx

M6 (8.8) 9

1FW6090-xxB05-xxxx to

1FW6090-xxB15-xxxx

M5 (8.8) 5.2

1FW6130-xxB05-xxxx to

1FW6130-xxB15-xxxx

M5 (8.8) 5.2

1FW6150-xxB05-xxxx to

1FW6150-xxB15-xxxx

M6 (8.8) 9

1FW6160-xxB05-xxxx to

1FW6160-xxB15-xxxx

M8 (8.8) 21.6

1FW6160-xxB20-xxxx M8 (10.9) 31.8

1FW6190-xxB05-xxxx to

1FW6190-xxB15-xxxx

M8 (8.8) 21.6

1FW6190-xxB20-xxxx M8 (10.9) 31.8

1FW6230-xxB05-xxxx to

1FW6230-xxB15-xxxx

M8 (8.8) 21.6

1FW6230-xxB20-xxxx M8 (10.9) 31.8

Installation

5.6Specications for mounting torque motors

1FW6 built-in torque motors

76 Operating Instructions, 09/2022, A5E52220812B AA

Loading...

Loading...