Electrical connection

6.1 Connecting the machine

1MB..5/6 shaft height 71 ... 355

68 Operating Instructions, 07/2020, A5E41926185A

Risk of explosion by fixing elements becoming loose

If you use fixing elements made from the wrong material or apply the wrong tightening

torque, this could impair current transfer or cause connecting parts to become loose.

Fastening elements can work loosely, so that the minimum air clearances are no longer

maintained. Sparking formation may occur, in an explosive atmosphere it can lead to an

explosion. This could result in death, serious injury or material damage to the machine or

even in failure, which could in turn lead indirectly to material failure of the system.

• Tighten the screwed connections to the specified tightening torques.

• Observe any specifications regarding the materials from which fixing elements must be

made.

• When performing servicing, check the fastenings.

6.1 Connecting the machine

6.1.1 Selecting cables

Take the following criteria into account when selecting the connecting cables:

• Rated current

• Rated voltage

• If required, service factor

• System-dependent conditions, such as ambient temperature, routing type, cable cross-

section as defined by required length of cable, etc.

• Configuration notes

• Requirements according to IEC/EN 60204-1

• Dimensioning for bundled cable routing, e.g. according to DIN VDE 0298 Part 4 or

IEC 60364-5-52

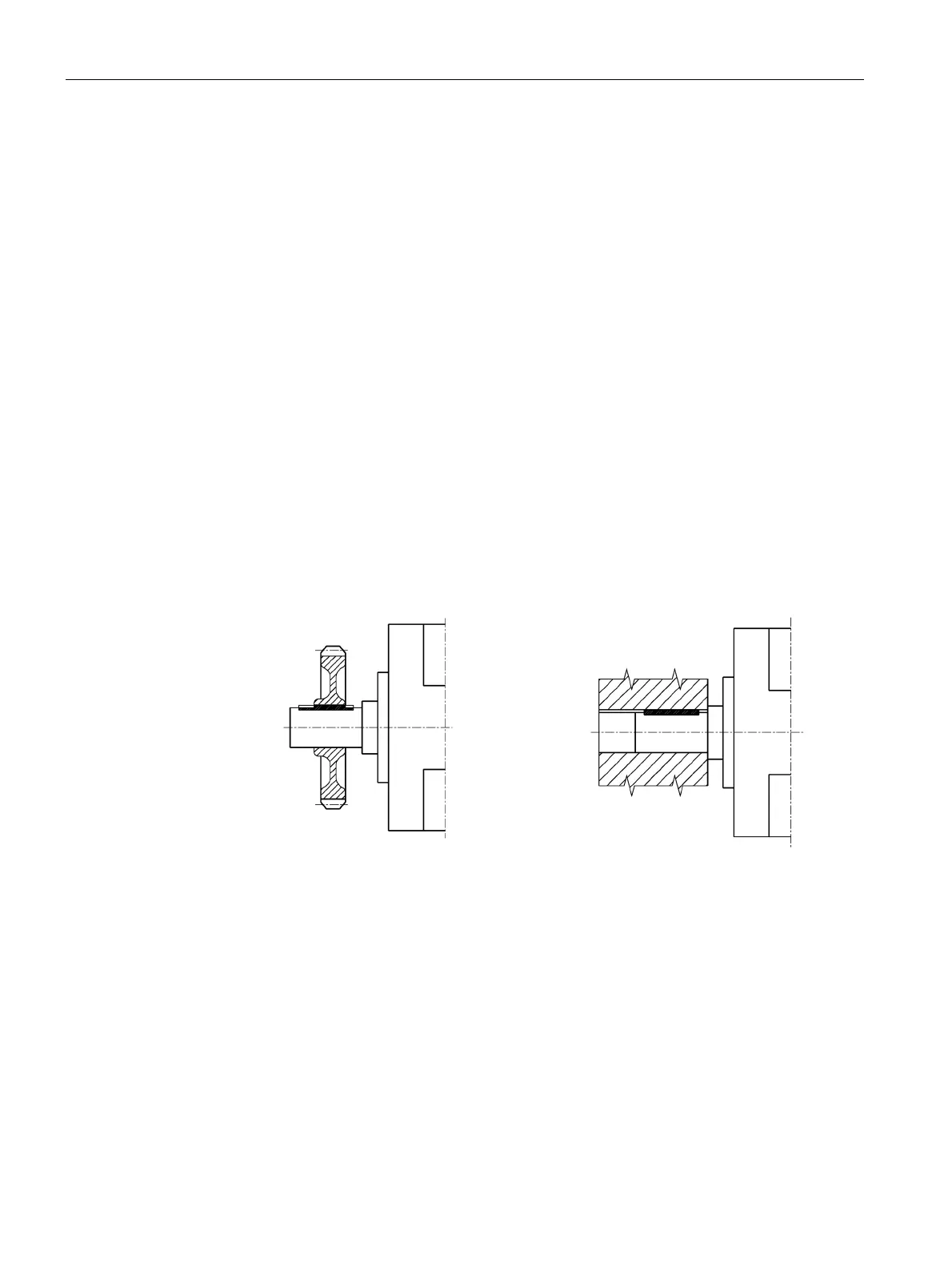

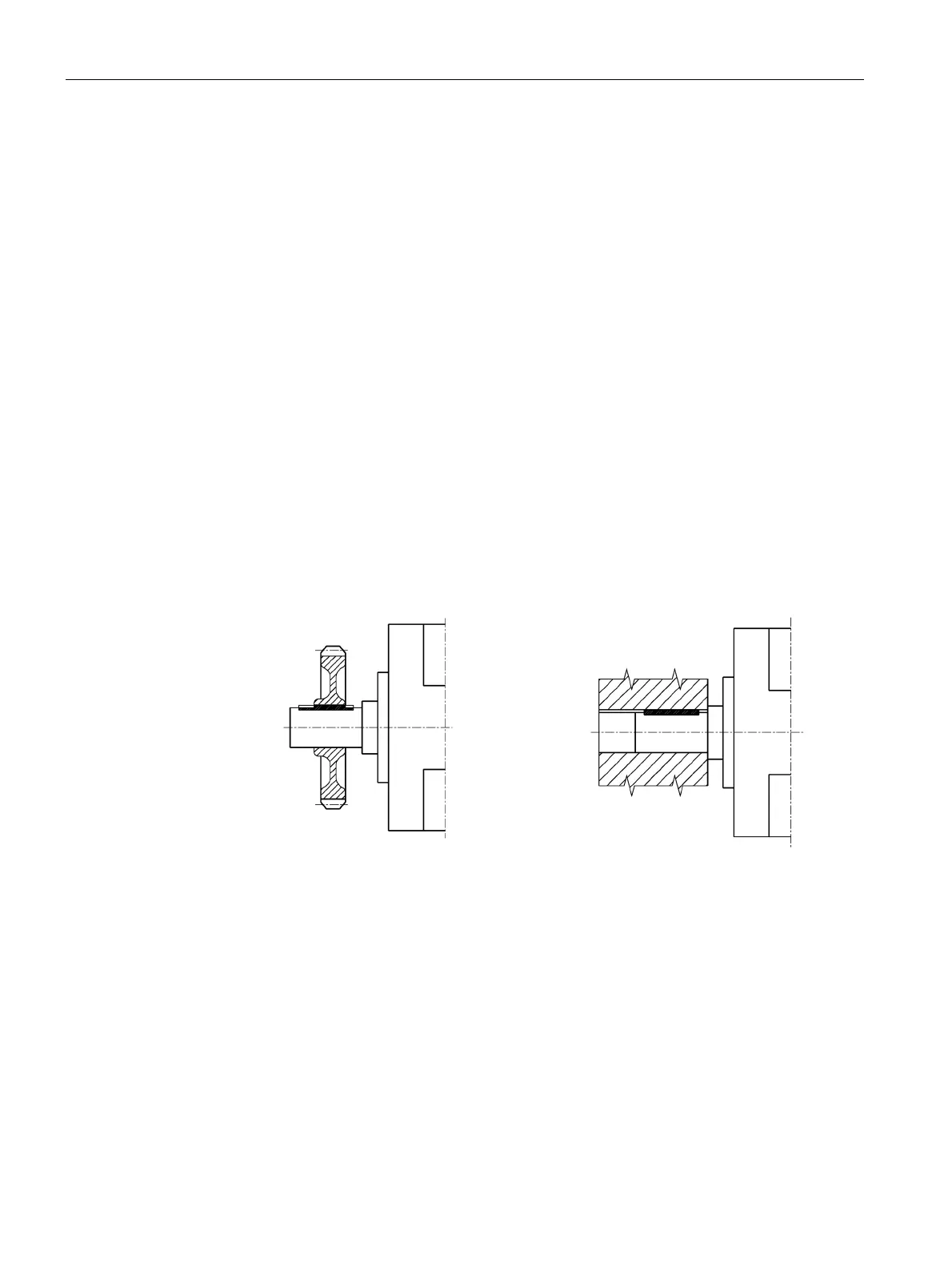

6.1.2 Terminal box

Electric motors have high voltages. When incorrectly handled, this can result in death or

severe injury.

Switch off the machine so that it is in a no-voltage condition before you open the terminal

Loading...

Loading...