Description

1.3 The fundamentals of motion control

SIMOTION C

20 Operating Instructions, 02/2012

1.3 The fundamentals of motion control

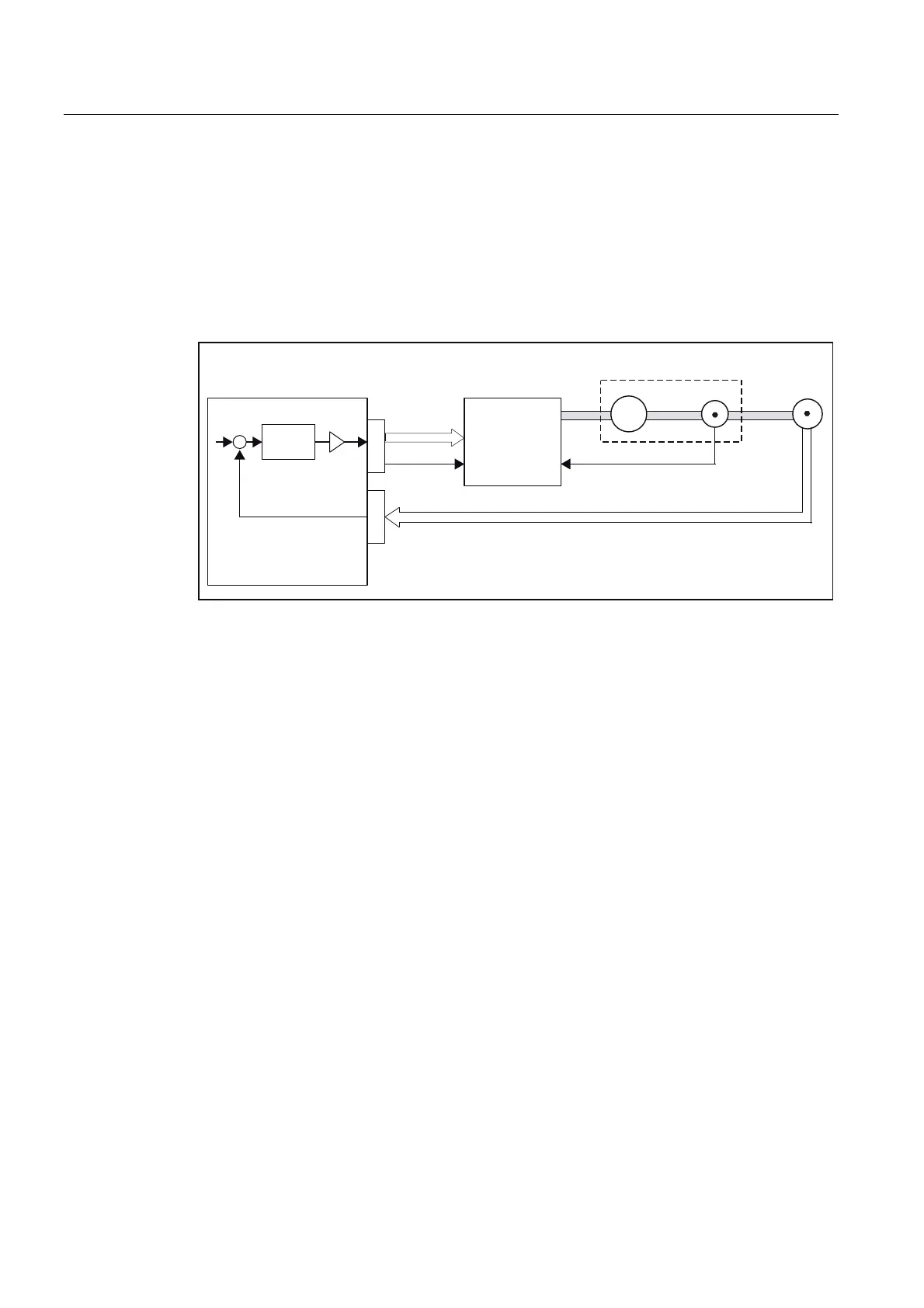

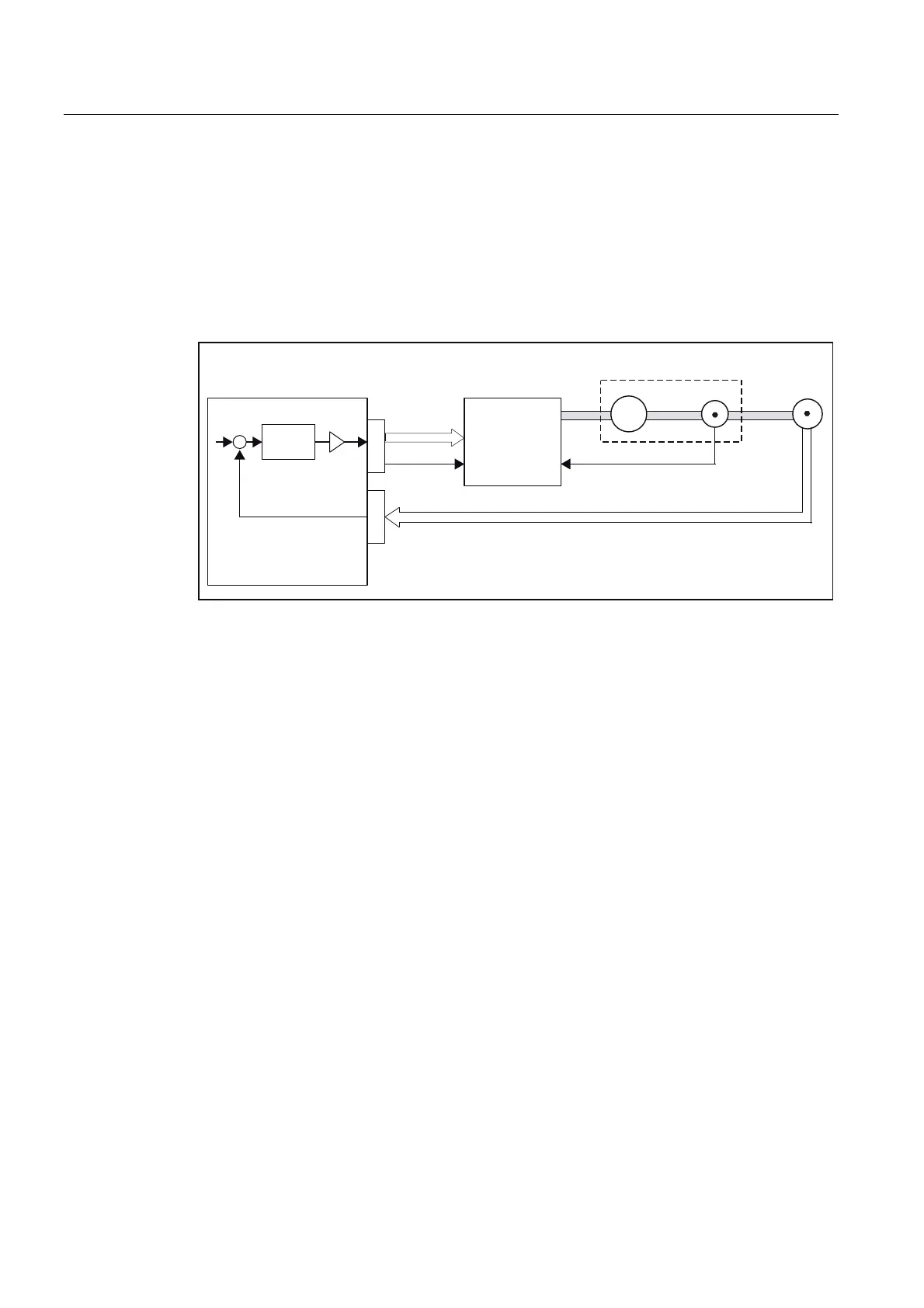

Position-controlled motion control for servo axes via the onboard drive interface (C230-2, C240)

These enable position-controlled motion control of up to four axes. The C230-2/C240

provides one analog output per axis for the speed setpoint and one encoder input per axis

for the cyclic measurement of the actual position value.

&RQYHUWHU

$FWXDOSRVLWLRQYDOXH]HURPDUN

(QFRGHU

$FWXDOVSHHGYDOXH

6HUYRPRWRU

6SHHG

FRQWUROOHU

&XUUHQW

FRQWUROOHU

3RZHUXQLW

UHOHDVH

6SHHG

VHWSRLQW

'$&

3RVLWLRQ

FRQWUROOHU

;

;

0

a

;

;

;

&&

Figure 1-4 Servo system with converter, e.g. SIMODRIVE 611 universal, with built-in incremental

encoder

Incremental encoder (C230-2, C240)

For position measurement, the encoders usually connected supply counting pulses

according to their resolution for the distances traveled. These can be rotary encoders or

linear scales.

Homing is necessary to determine the absolute position reference.

Absolute encoder (SSI, C230-2, C240)

Instead of conventional incremental encoders, which supply only a relative dimension for the

distance traveled, absolute encoders with a serial interface can be connected. No homing

operation need be performed for these encoders as they always supply the absolute position

as an actual value.

A one-time adjustment is required for an axis with an absolute encoder when the machine is

initially commissioned.

Loading...

Loading...