4.4 Thermal Overload Protection (ANSI 49)

315

7UM61 Manual

C53000-G1176-C127-3

4.4 Thermal Overload Protection (ANSI 49)

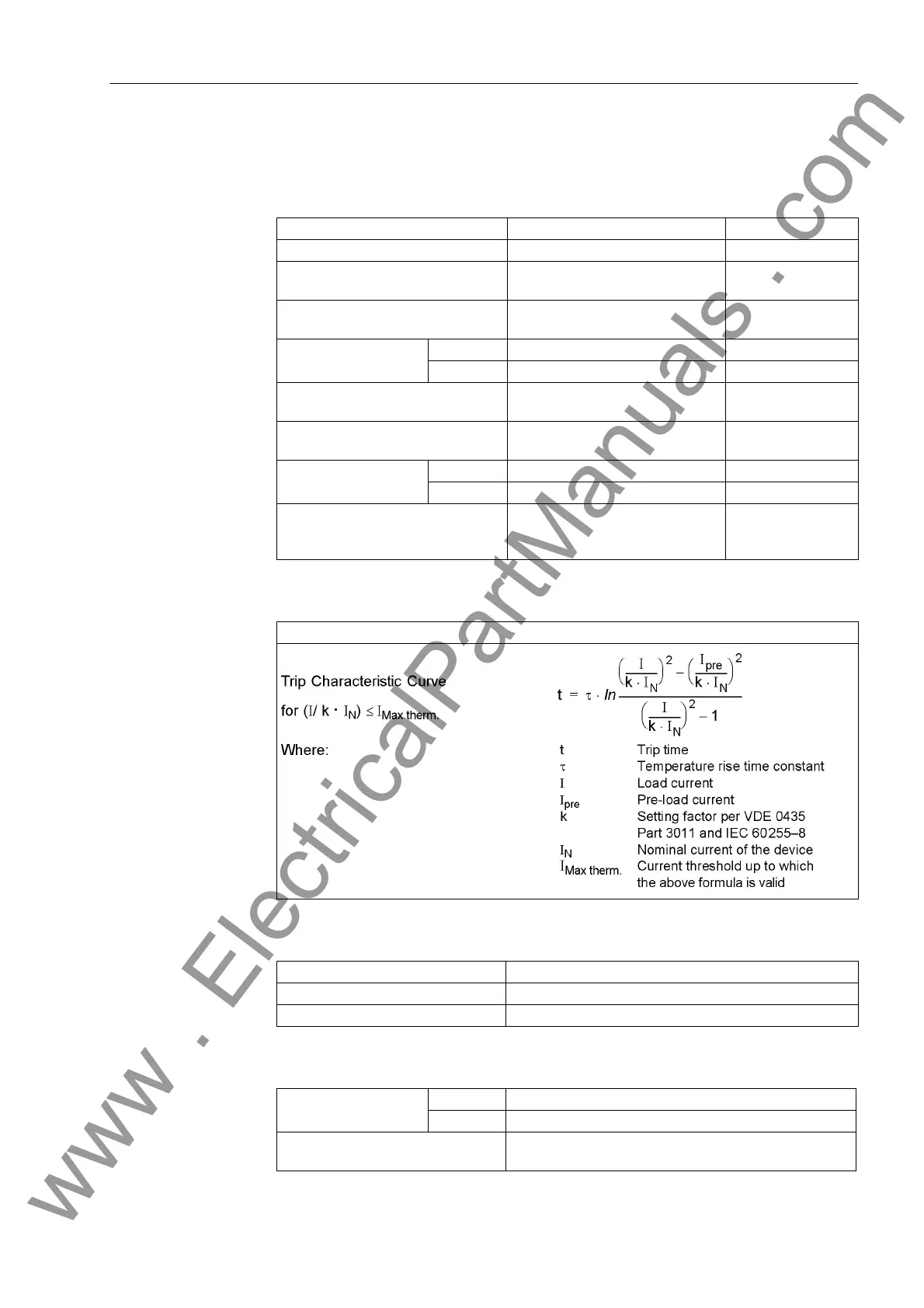

Setting Ranges / Increments

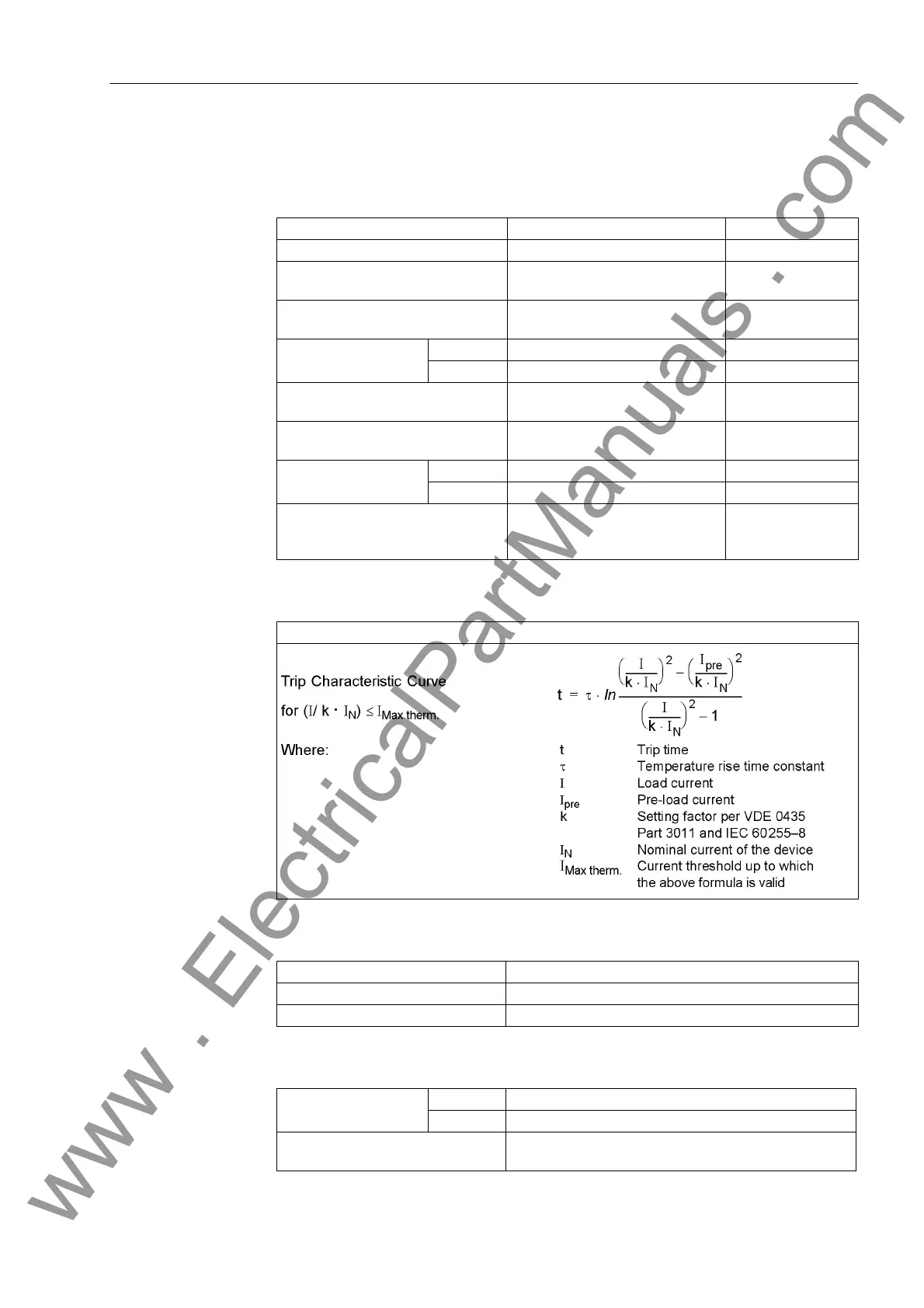

Tripping Characteristics

Dropout ratios

Tolerances

K-Factor per IEC 60,255-8 0.10 to 4.00 Increments 0.01

Time Constant τ 30 s to 32000 s Increments 1 s

Extension of Time Constant at

Standstill

1.0 to 10.0 Increments 0.1

Warning overtemperatureΘ

Alarm

/Θ

Trip

referred to the tripping temperature

70 % to 100 % Increments 1 %

Current Overload I

Alarm

for I

N

= 1 A 0.10 A to 4.00 A Increments 0.01 A

for I

N

= 1 A 0.50 A to 20.00 A Increments 0.05 A

Nominal Overtemperature (for I

Nom

)40° to 200 °C / 104 °F to 392 °F (Increments 1 °C)

(Increments 1.8 °F)

Coolant Temperature for Scaling 40° to 300 °C / 104 °F to 572 °F (Increments 1 °C)

(Increments 1.8 °F)

Limit current I

Limit

for I

N

= 1 A 0.50 A to 8.00 A Increments 0.01 A

for I

N

= 5 A 2.00 A to 40.00 A Increments 0.05 A

Dropout Time after Emergency Start-

ing

T

Emergency Start

10 s to 15000 s Increments 1 s

see also Figure 2-15

Θ/Θ

Off

Dropout with Θ

Alarm

Θ/Θ

Alarm

approx. 0.99

I/IAlarm approx. 0.95

referred to k · I

N

for I

N

= 1 A 2 % or 10 mA ; class 2 % acc. to IEC 60255-8

for I

N

= 5 A 2 % or 50 mA ; class 2 % acc. to IEC 60255-8

referred to Trip Time 3 %, or 1 s, Class 3 % acc. to IEC 60255-8

for I/(k ·I

N

) > 1,25

www . ElectricalPartManuals . com

Loading...

Loading...