Instructions, use and maintenance manual Pag. 36/49

SAU 160-200

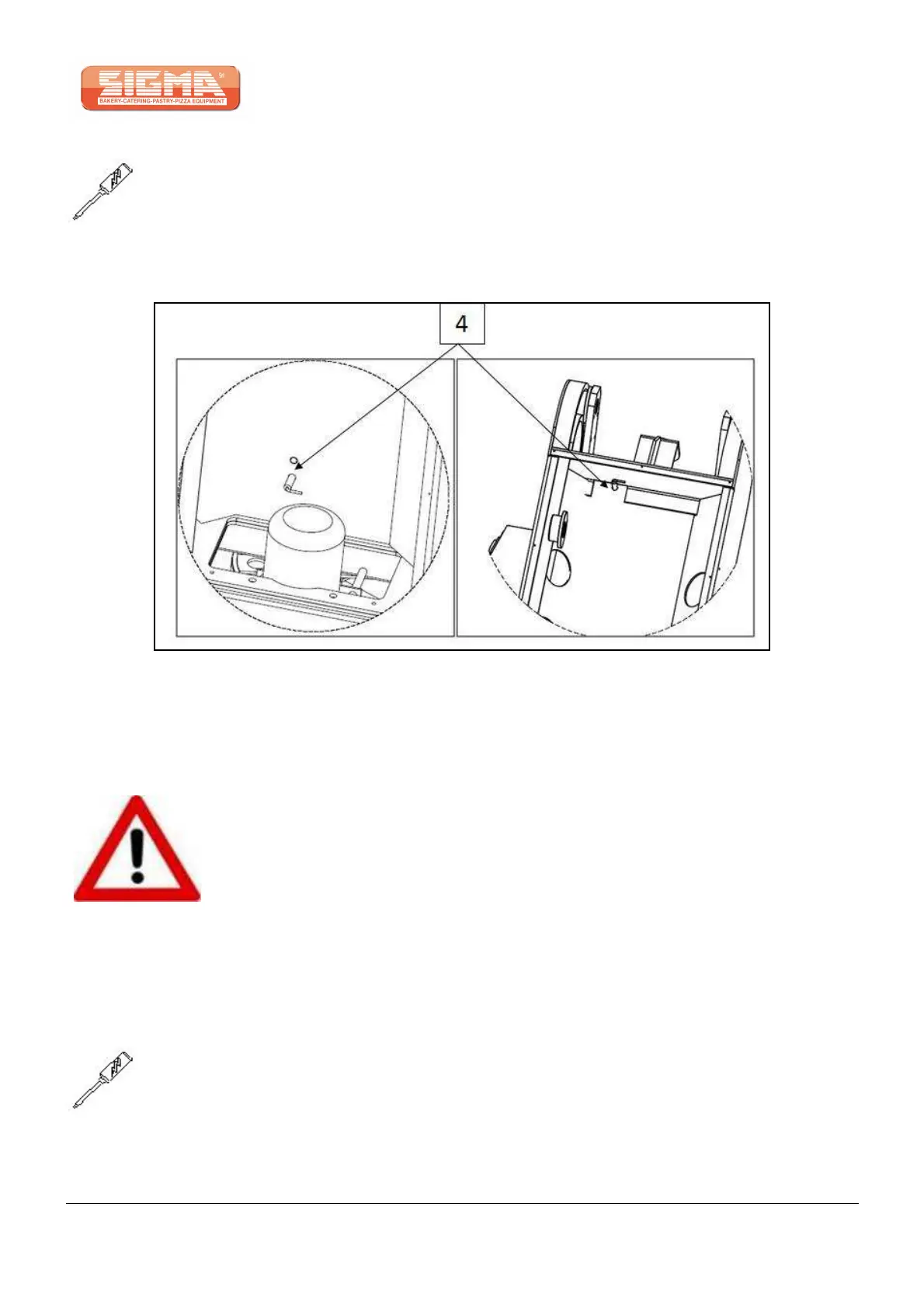

replacement of the mixer machine lifting and/or lowering proximity

: remove the rear

casing of the lifter.

Check the proximity, change it in case of failure and/or breakage. When disassembling/assembling the

proximity, tighten/loosen the ring nuts (4).

Should the power cable be damaged, replace it with a H07RN/F cable with a 3x1.5 mm cross-section.

Electrical interventions: they must be carried out by a qualified electrician, referring to the diagrams

attached at the end of the manual.

Please note that both the cam screws and the micro

switch screws are blocked with

Bblock230, which is a product suitable for clamping screws and/or nuts that come

loose due to vibrations (Bblock230 is a highly resistant product and can only be

removed by heating the product at about 250°C (with naked flame or furnace);

obviously, check that the product does not contain material flammable at this

temperature). Before using Bblock230, make sure that the micro-switch is correctly

positioned, block it, put the square back on the head and fasten it, put the upper

casing back and tighten the screws. Turn on the machine, if it works properly it

should stop in FOUR seconds from lifting the mobile guard. Ensured that the

machine works properly, release the master switch, remove the rear casing, loosen

the ring nut, put the thread locker and tighten it. Put the casing back and tighten the

screws.

For the proximity, remove the rear casing of the lifter and replace the faulty

proximity. Ensured that the machine works properly, release the master switch,

remove the rear casing, loosen the ring nut, put the thread locker and tighten it. Put

the rear casing back and tighten the screws.

Loading...

Loading...