Instructions, use and maintenance manual Pag. 34/49

SAU 160-200

14.5.2. How to tension belts and chain

-) Describe how to properly tension a drive belt is very complicated.

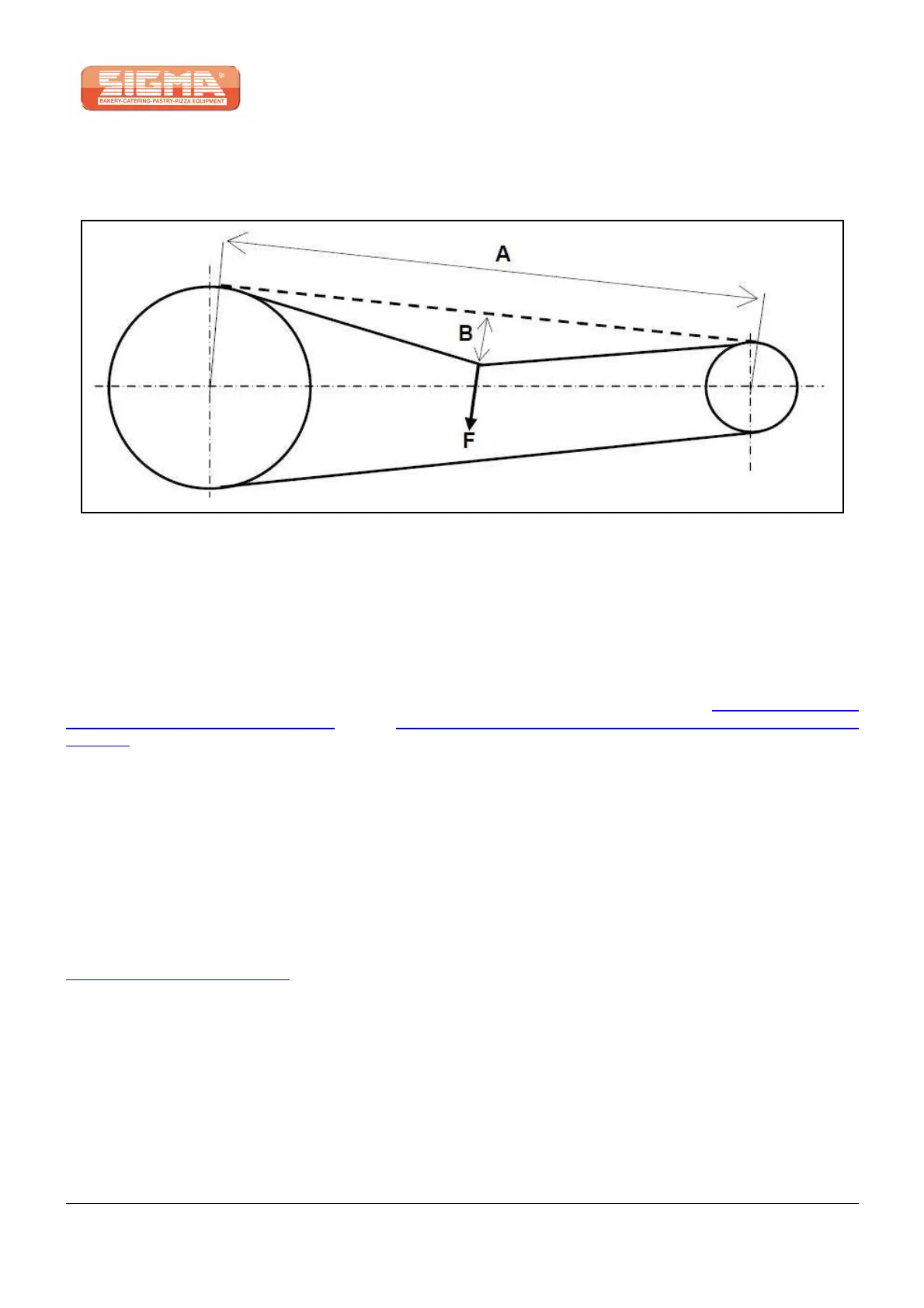

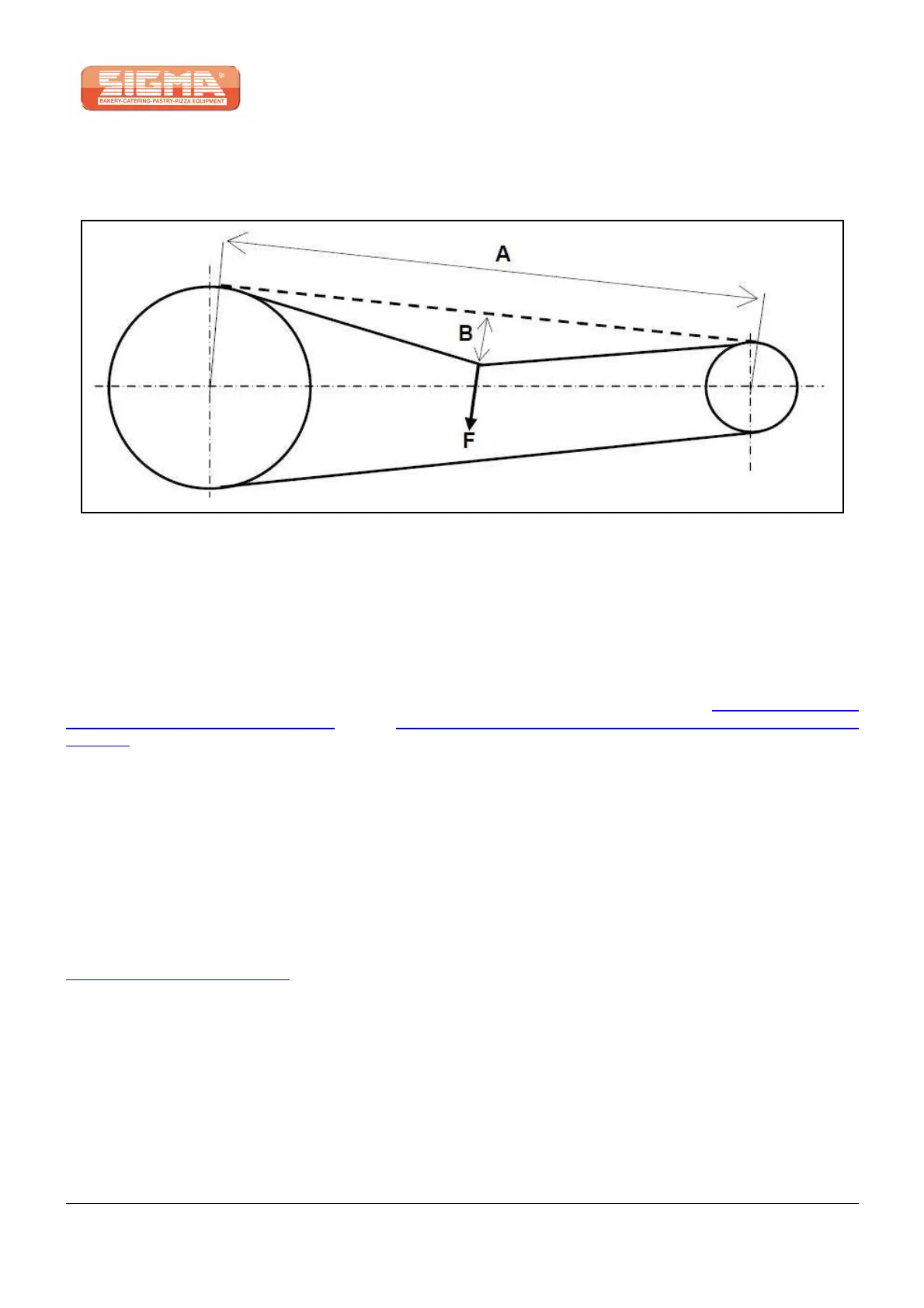

- measure the length of free section A in mm

- halfway on free section A and perpendicularly to the same, apply force F required to bend the belt (arrow) B (mm)

equal to A/100 (e.g. if A=500 mm, B=5,0 mm), use a millimetric reference to measure arrow B;

- the belt tension is correct if the force F applied for arrow B is between 12 and 18 N; measure the force using a

dynamometer or, even better, a tensiometer, which normally allows detecting arrow B; both are readily available on

the market.

For further information contact the seller or consult these sites: http://www.sitspa.it/it-

IT/Trasmissioni_a_cinghia_Poly-V.html e http://www.megadyneveneto.it/index.php/it/component/k2/item/223-

pluriband.

-) Describe how to properly tension a drive chain is also very complicated.

The chain tension is correct when, by pushing it with your thumb halfway on the free section, it is not rigid

(otherwise it could break), but gives slightly and when released it goes back as it was; the chain meshes must be

free enough to rotate on the pins but not sag (otherwise they might come out of the gears).

If the user reasonably doubts his ability to to adjust the chain tension, do not use the machine and contact the

manufacturer as soon as possible for instructions.

http://www.ognibenechaintech.it/.

Loading...

Loading...