Instructions, use and maintenance manual Pag. 37/49

SAU 160-200

14.7. Machine cleaning

Daily Checks

Always keep the machine clean to prevent the formation of micro-organism colonies that can alter the

end product and be harmful to health. It is also important that flour does not deposit on moving parts,

thus creating annoying squeaks and abnormal wear.

INTERVAL METHOD

g F,M

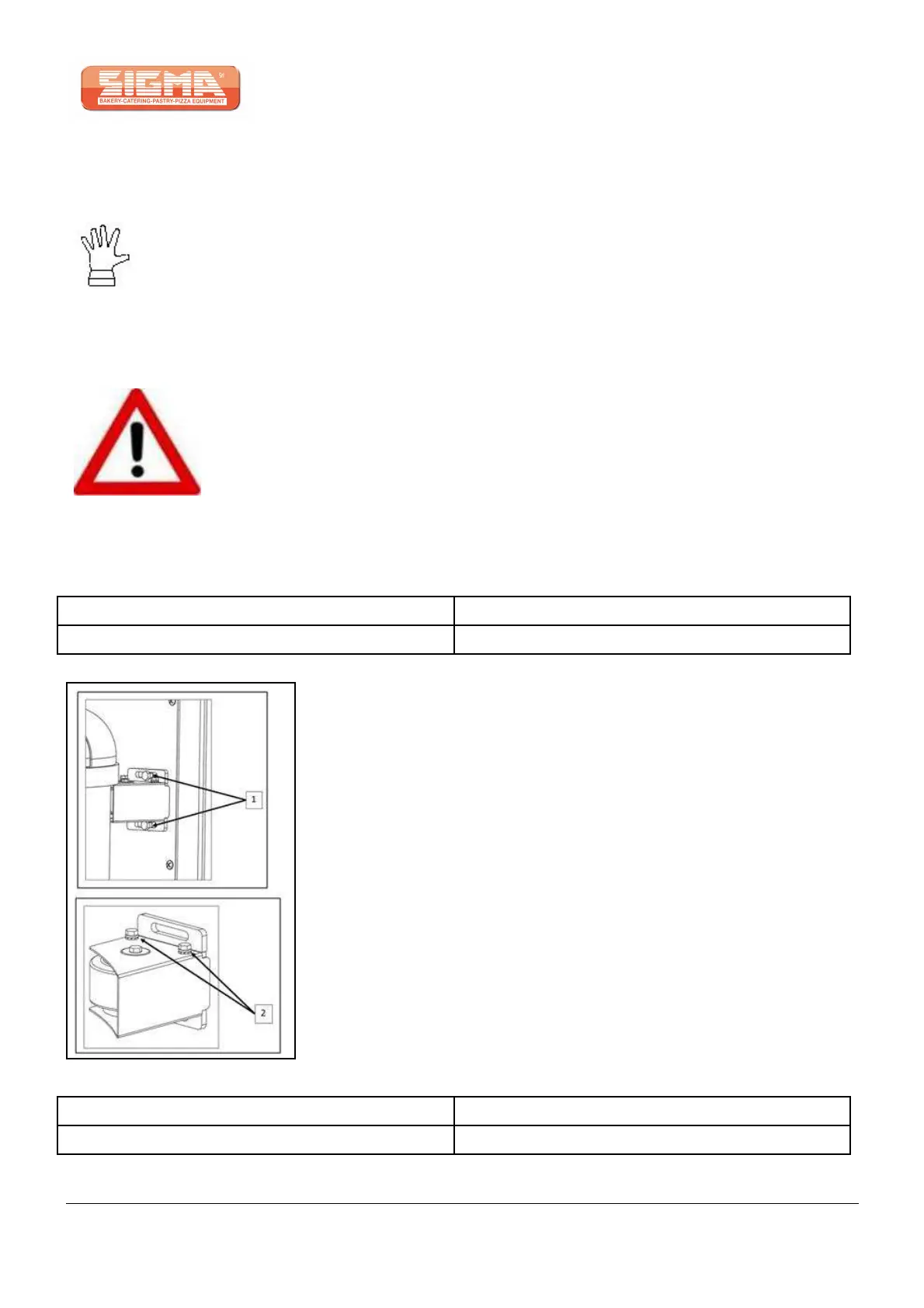

Cleaning the bowl contrast block:

Remove the two bowl contrast blocks by loosening the screws (1). After

removing the block, loosen the four screws (2), take off the wheel cover and

wearing a mask, clean the wheel using a clean brush and then a damp cloth.

Replace the wheel cover and block the screws (2) and then tighten the contrast

block back on the column via screws (1).

ATTENTION: check that the distance between the bowl and its contrast block

is 4 mm.

DO NOT MODIFY THIS SAFETY VALUE.

INTERVAL METHOD

s F,M

FOR ANY MAINTENANCE AND CLEANING OPERATIONS, THE MACHINE MUST BE

OFF AND DISCONNECTED FROM THE ELECTRIC LINE.

Cleaning: the machine is not spray-proof; it must not be cleaned with running water

or compressed air, to minimise dust movement. To vacuum the dust, use a

professional vacuum equipped with adequate filters depending on the grain size of

the flour.

Cleaning the bowl: use a damp cloth and/or PLASTIC spatulas with water only.

N.B.: it is not advisable to use metal spatulas to clean the bowl.

Cleaning the column and spiral: use a damp cloth with water only. Mop between the

bowl and column and/or between the bowl and spiral to avoid the formation of

contaminated areas.

Loading...

Loading...