Operating Manual SIGMA 4-15C, page 37 of 95

03/06

3.3 Installation of Rotors and Accessories

1. Open centrifuge lid by pressing Lid-key.

2. Unscrew rotor tie-down screw from motor shaft (anticlockwise).

3. Lower the rotor straight down onto the motor shaft.

4. Tighten the tie-down screw (clockwise) with the rotor wrench so that the disc

spring is pressed together.

Fastening torque: 1-6/1-15/2-5/1-15K/2-16/2-16K/2-16KC: approx. 5 Nm

3-16/3-16K/3-18K/3K 30: approx. 7,5 Nm

4-15/4K15/6-15/6K15: approx. 10 Nm

In the event of frequent use the tie-down screw must be loosened by some

turns and fastened again. This should be done once a day or after approx.

20 cycles (please refer to chapter 5.1.4 “Alteration of the Configuration“

– Cycles). This ensures a proper connection between rotor and shaft (please

refer to chapter 8.2 "Care and cleaning of accessories" as well).

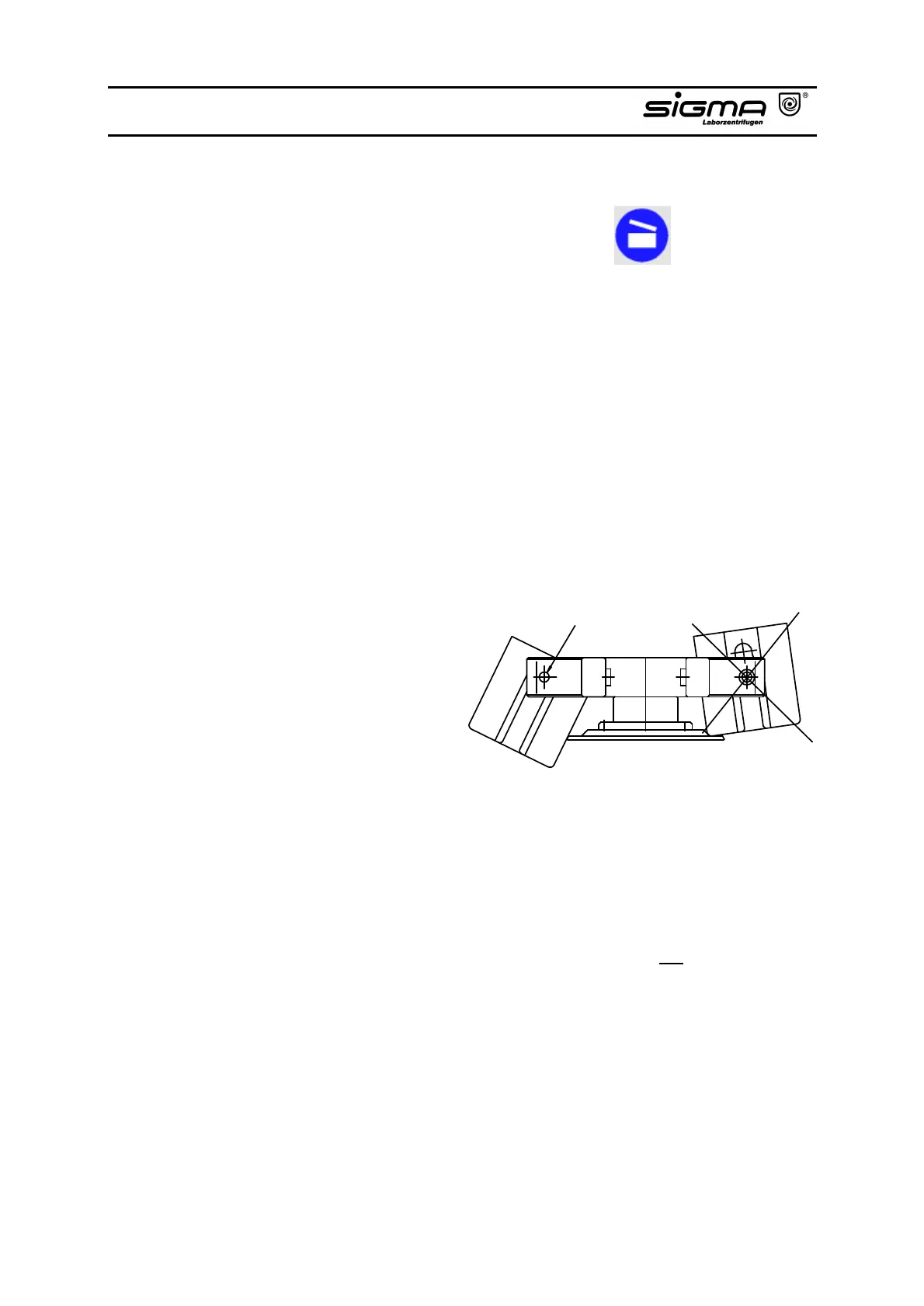

5. Fill all positions of swing-out

rotors with buckets. Make

sure that all buckets are

inserted correctly.

6. Use only appropriate vessels

for the rotor (please refer to

chapter 1.2 "Suitable acces-

sories" as well).

Universal grease

allowed not allowed

7. Fill vessels external to the centrifuge.

8. Put or screw on covers of vessels.

9. Opposite places of the rotors must always be loaded with same accessories

and same filling.

10. Attention when using microtiter rotors: It is important not to run the plate

holders without plates inserted.

11. In angle rotors the plastic vessels must always be totally filled to avoid cracks

of vessels and leakages or loosening of the caps in case of partial filling.

Attention, follow the special comments of chapter 1.5.

Loading...

Loading...