22 User Manual

Setup Assistant

10. Z Axis calibration

To carry out the following

process, when indicated on

the screen, apply a thin and

uniform layer of glue stick on

the entire printing surface

glass to ensure a better

calibration.

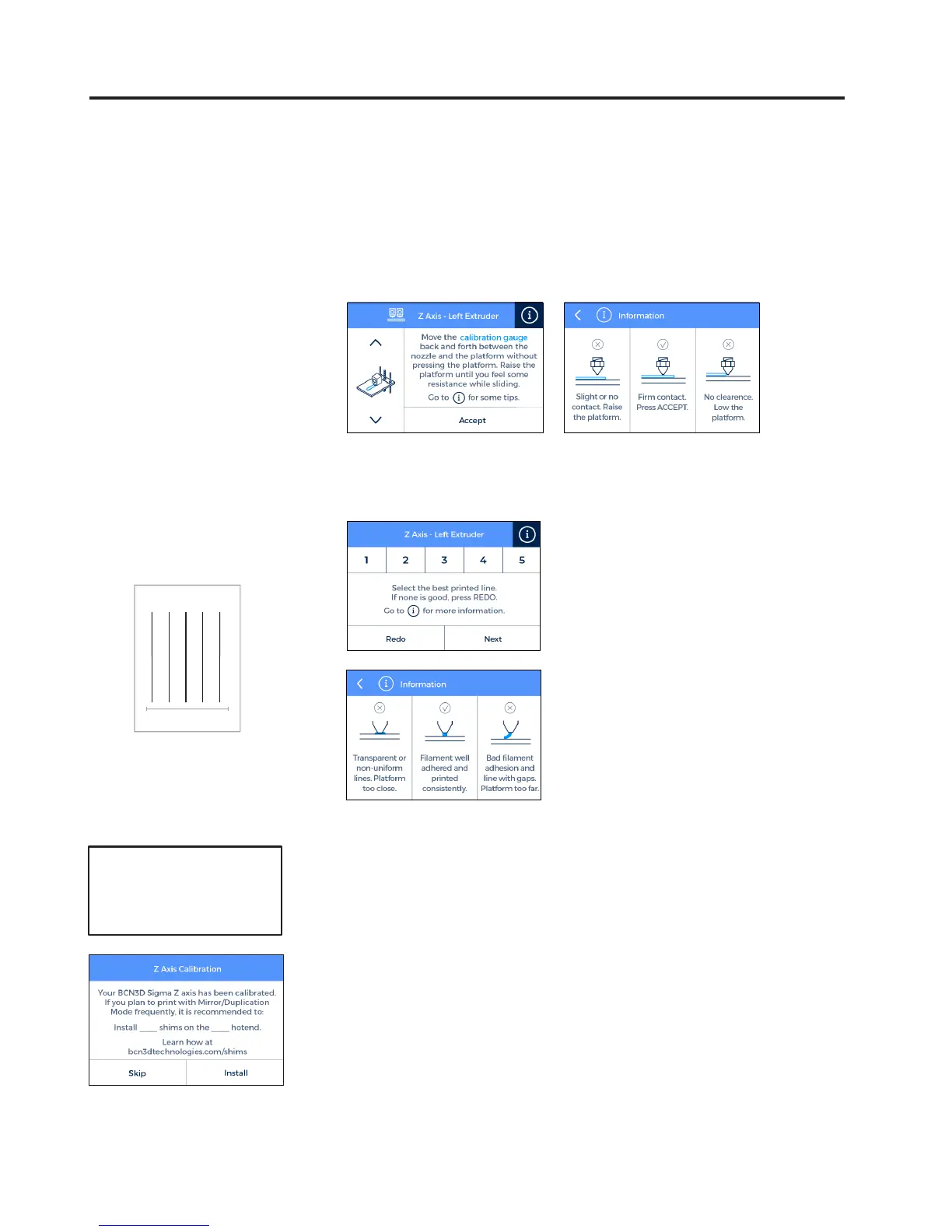

11. Place the Calibration Gauge between the nozzle and the

printing surface glass. Hold the gauge by the end and move

it back and forth, without pressing the platform. Raise the

platform until you feel some resistance while sliding the

gauge. The gauge should not flex.

· If the nozzle is too close

to the glass, the line will be

transparent or non-uniform.

· The line must be adhered to

the printing glass and with

no gaps.

· If the nozzle is too far to

the glass, the line won’t

be properly adhered to the

printing glass and will be

gaps in it.

13. Select the best line. 12. The printer will print a

test to validate the previous

process.

1 5

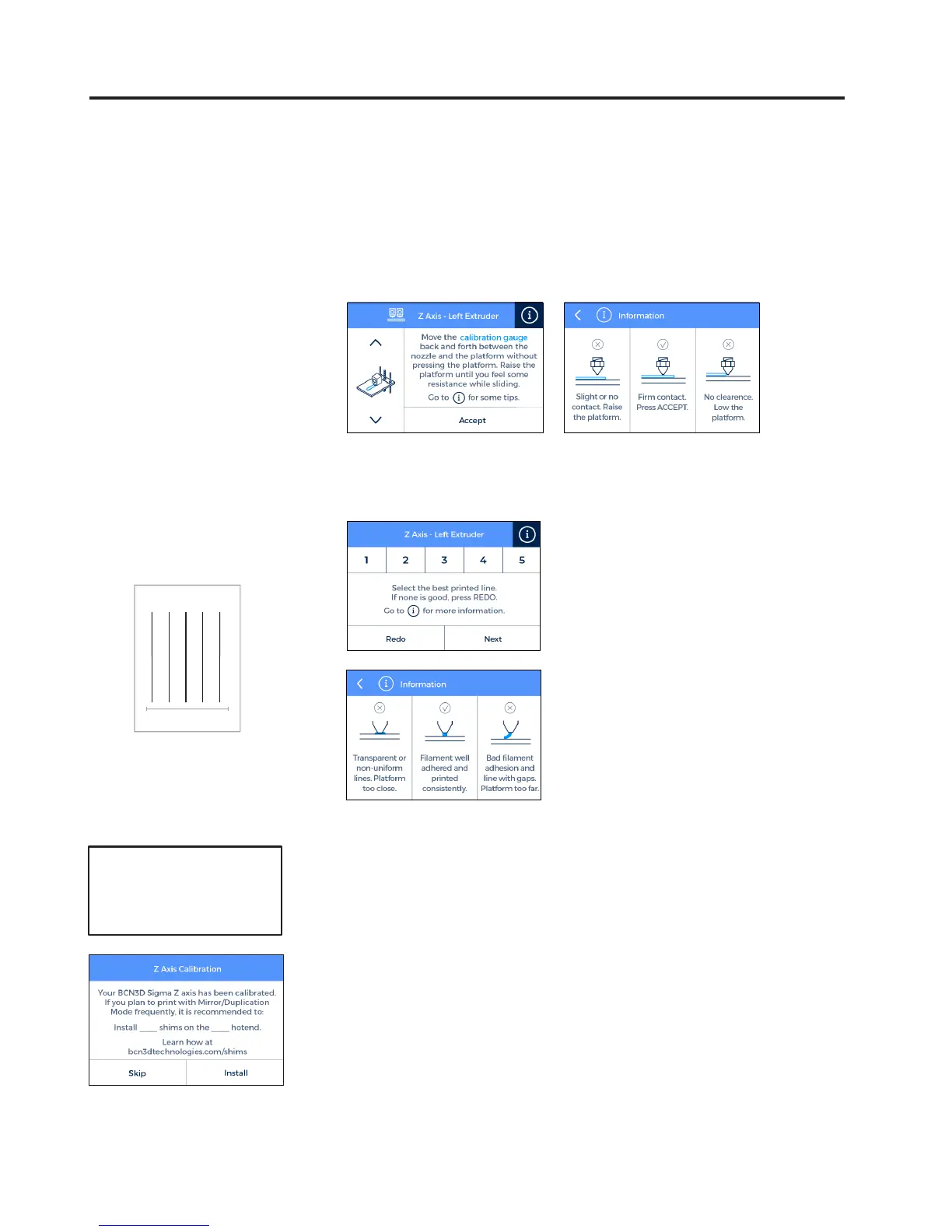

NOTE: Depending on the

Z axis calibration, it may

appear this recommendation

screen.

If so, please check next

section: “Installing shims”

(page 26) for a detailed

explanation of the reason,

benefits and procedure to

perform this operation.

14. Repeat processes 11-13

for the second extruder.

Loading...

Loading...