MDD 121-1

10.03.2021 Page 31

3.3.4 Connector properties

All connections of the servo drive system (except the ground bolt) are plugging style

connectors. This makes it easier to install the cables and to replace a drive. Never the less

it also opens the possibility to create cable sets for high volume machines.

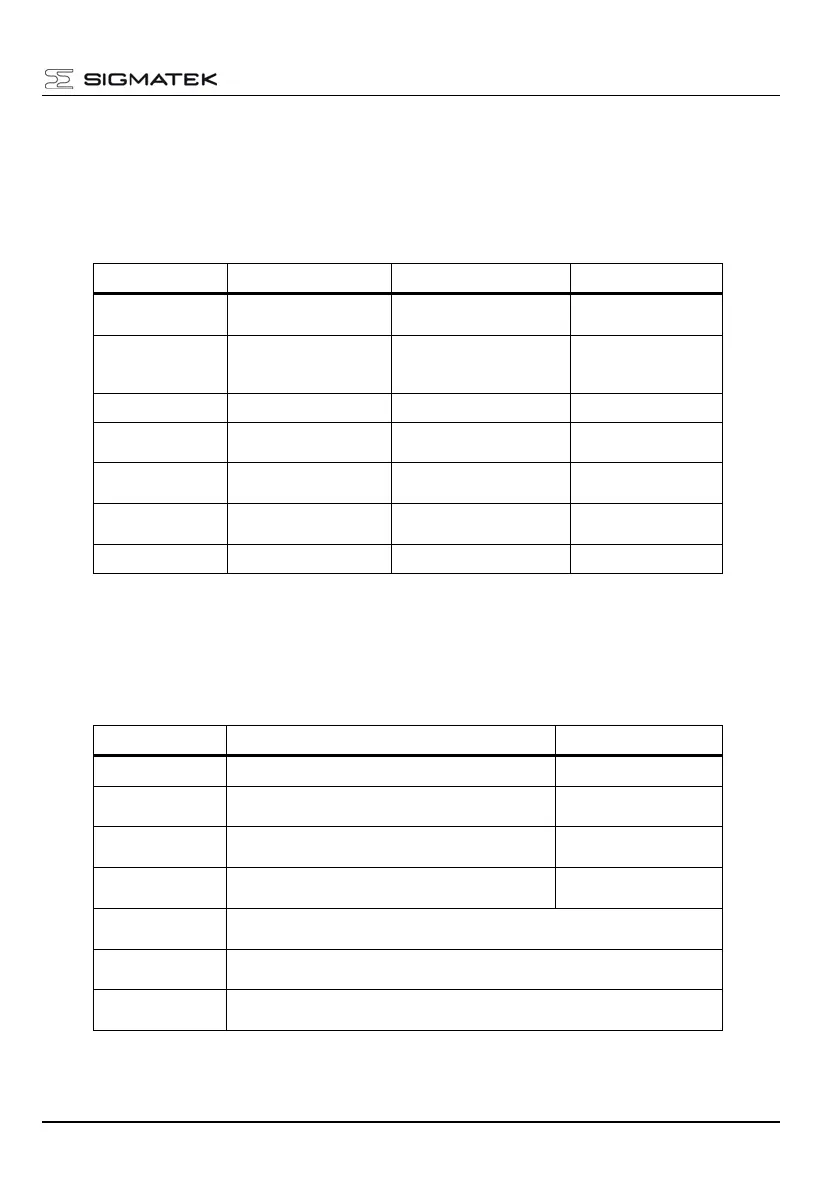

The mechanical properties of the interface connectors are:

0.2 – 1.5 mm² (16 – 24

AWG)

Phoenix

GMSTB2,5HCV/9-ST-

7,62

1 – 2.5 mm² (14 – 16

AWG)

0,56-0,79 Nm

(5-7 inch lb)

0.2 – 1.5 mm² (16 – 24

AWG)

D-Sub 25 with metal

housing

0.25 – 0.5 mm² (20-22

AWG)

1 – 2.5 mm² (14 – 16

AWG)

0,56-0,79 Nm

(5-7 inch lb)

3.3.5 Wire sizing

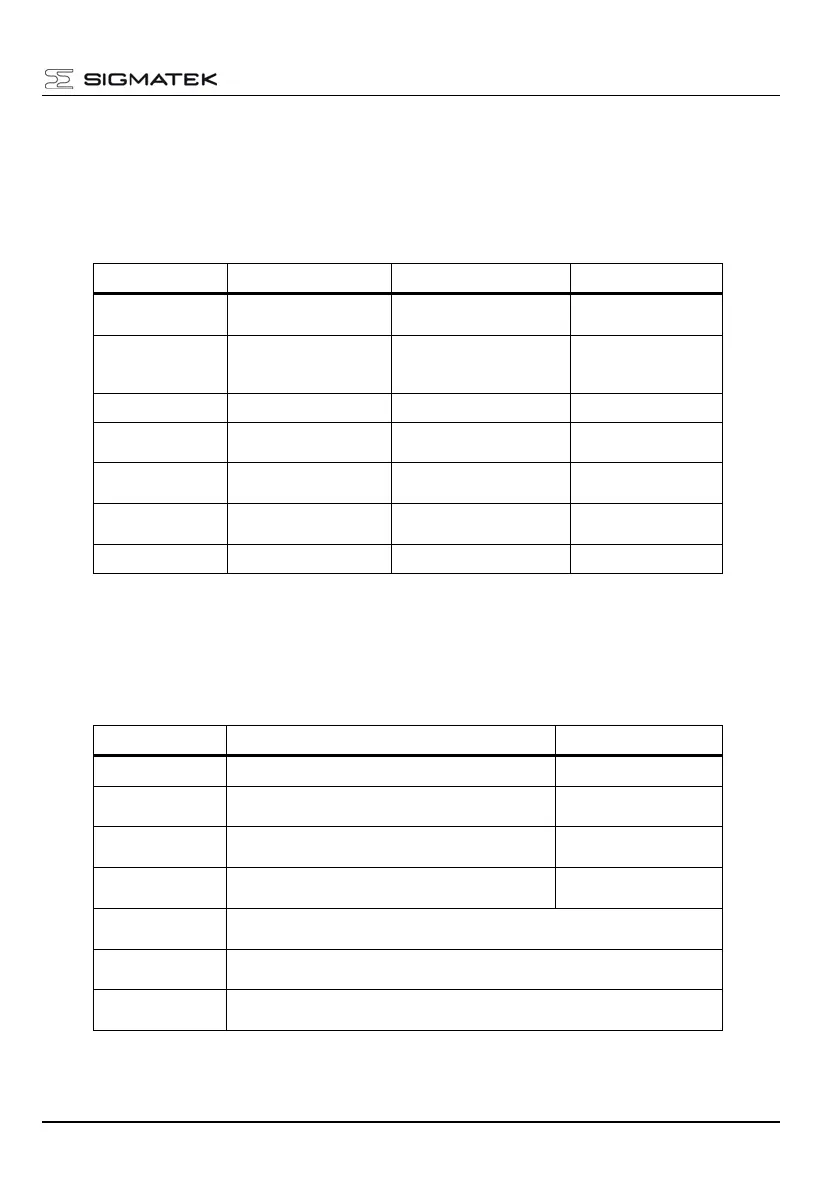

According to EN 60204 (for AWG: table 310-16 of the NEC 60 °C or 75 °C column), we

recommend

1.0 mm² (16 AWG), shielded, max.25 m,

capacitance <150 pF/m

Min. 0.5 mm² (18 AWG), part of the motor cable,

shielded separately, check voltage drop

Resolver with

thermal contact

4x2x0.25 mm² (22 AWG), twisted pairs, shielded, max.25 m, capacitance

<120 pF/m

7x2x0.25 mm² (22 AWG) twisted pairs, shielded, max.10 m, capacitance

<120 pF/m

Maximum 2.5 mm² (14 AWG), check voltage drop

Note: Use 60/75 °C Copper conductors only!

Loading...

Loading...