47

OPERATION AND ADJUSTMENTS

(Refer to the exploded views for key number

identification)

As strap is pulled from the dispenser, the dancer

arm swings forward to allow the coil to rotate

and pay-off the strap. The forward motion of the

dancer arm is gradually absorbed by a

compression spring (19) and the arm should stop

within an inch of contacting the forward stop

bumper (11). If, with a full coil of strap, the arm

impacts the bumper, increase the spring pressure

by turning the spring plunger (18) clockwise.

A nominal setting of the spring plunger will

result in it being positioned about 7/8" below the

top of the spring housing (14) when the arm is in

contact with the bumper (11).

If less tension is required, turn the plunger

counterclockwise but never loosen it beyond the

retaining screw (17).

As the arm swings back, a brake is applied to the

outer rim of the back disc assembly (7). The

brake should stop the coil from rotating. If the

coil is not stopped quickly enough and three or

four loose wraps of strap appear on the coil, the

brake will have to be adjusted.

To adjust the brake refer to the illustrations and

the steps below:

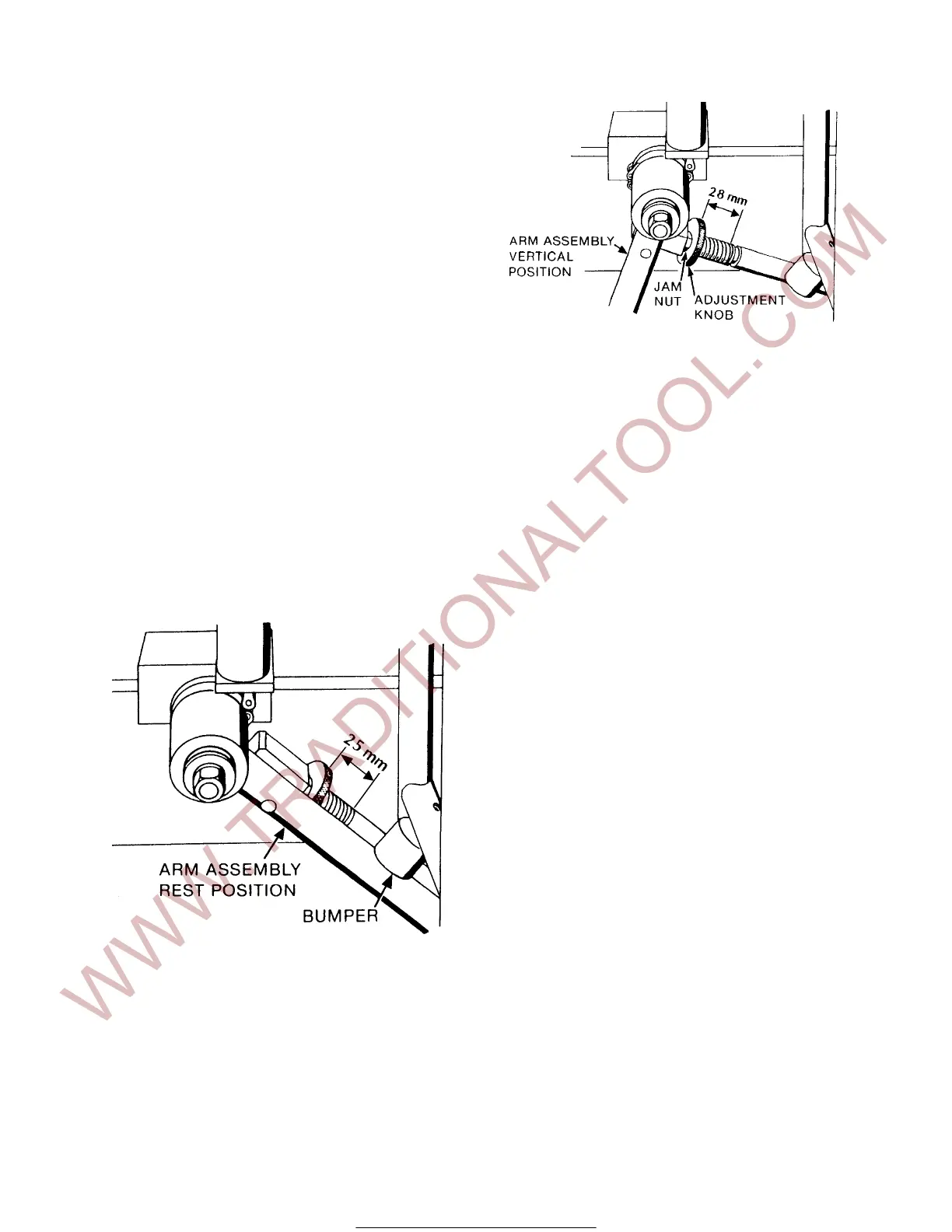

1. Hold the dancer arm assembly (24) in a

vertical position and measure the length of

the compression spring (33). The spring

should not be compressed with the dancer

arm vertical. The spring should measure 1

1/8" (28mm).

2. Loosen the set screw (31) in the knurled

adjustment knob (32) then loosen the jam

nut (30). This will allow the adjustment

knob (32) to be rotated.

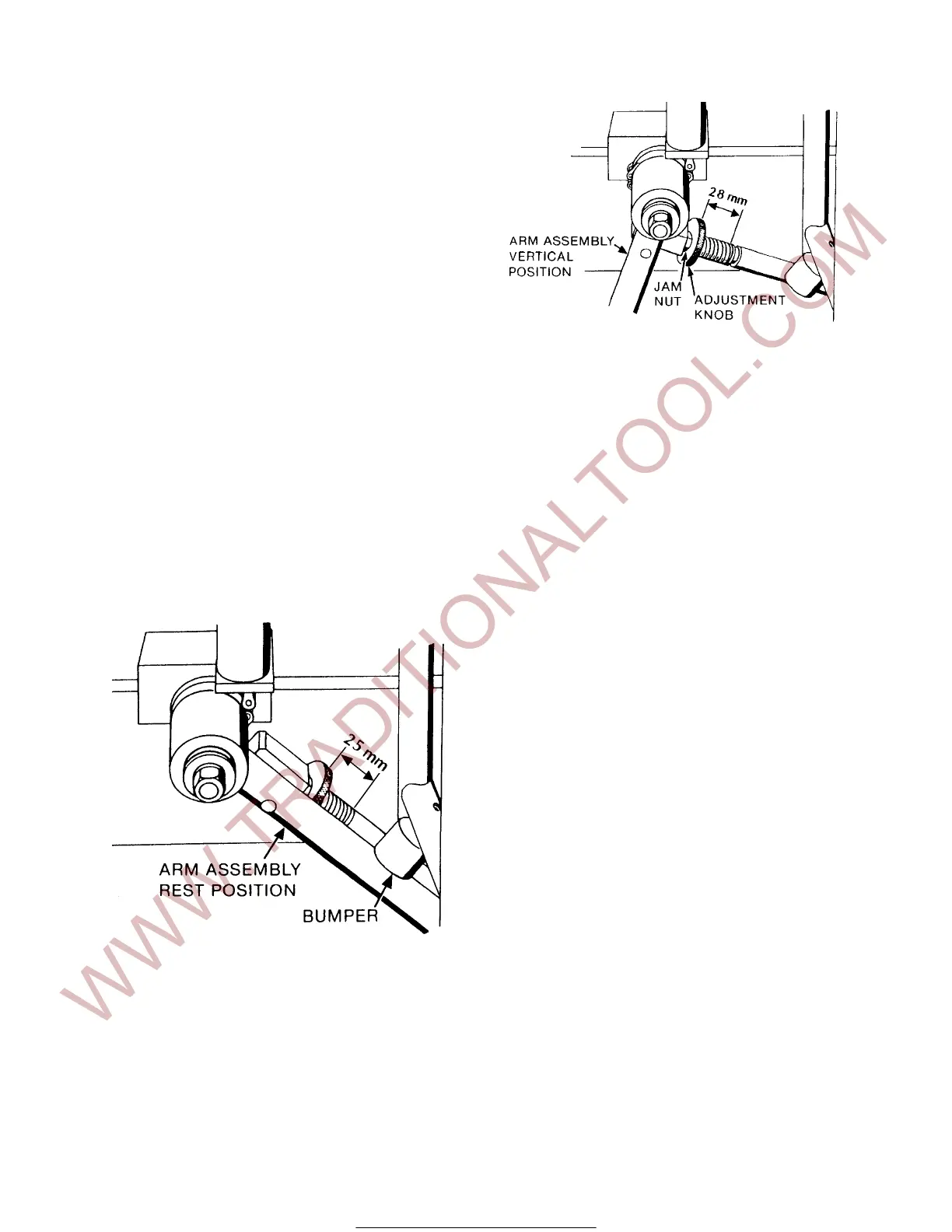

3. Move the dancer arm forward until it

contacts the bumper (11) and remeasure

the length of the compression spring (33).

It should measure 1" (25mm). If it measures

something other than 1", move the arm to

the vertical position and rotate the

adjustment knob in the direction needed to

obtain the 1" (25mm) dimension.

4. When set, tighten the jam nut (30) and the

set screw (31).

5. Note that the brake block (43) contacts the

outer flange with about fifty percent of the

length of the block. This means that the

block can be turned and reused in four

positions, greatly extending the life of the

block.

To properly position the block, place a

1/16" spacer between the lower part of the

block and the disc flange, then securely

tighten the mounting screw (42) and the

lock nut (45). Remove the spacer.

For Parts & Service 1-877-862-6699

Loading...

Loading...