Construction

20222303 / A 9

2 CONSTRUCTION

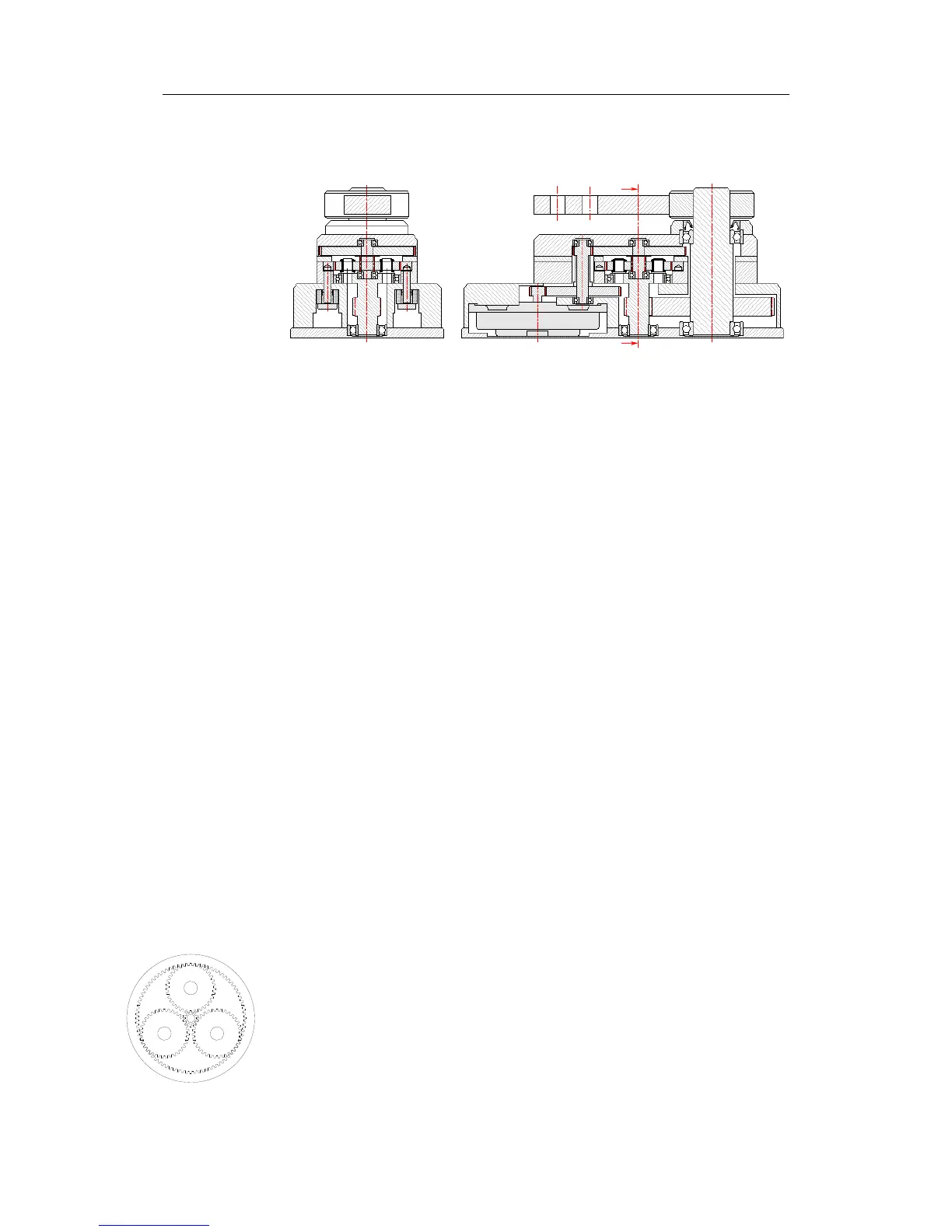

This assembly drawing shows a cross section of the direct drive.

The drive can be separated in 5 main parts: The electric motor,

the two step spur gearbox, the planetary gearbox, the electro-

magnetic clutch and the final spur reduction gearbox. The

Simrad direct drive has multiple advantages over existing

integrated drive units. These advantages will be explained per

section of the drive:

2.1 Electric Motor

The flat wound electric motor (pancake motor) used in the

Simrad direct drive is carefully selected for this application.

Pancake motors have multiple advantages over normal electric

DC motors:

• A large flat wound rotor to achieve a high starting toque and

an immediate response to the autopilot speed control signal.

• A motor efficiency of 72,5% to achieve a minimal power

consumption and maximal mechanical power output

(compared to max. 50% efficiency of a normal DC motor).

• Compact main dimensions compared to achievable output.

• Aluminum motor housing in stead of sheet steel plate to

avoid corrosion.

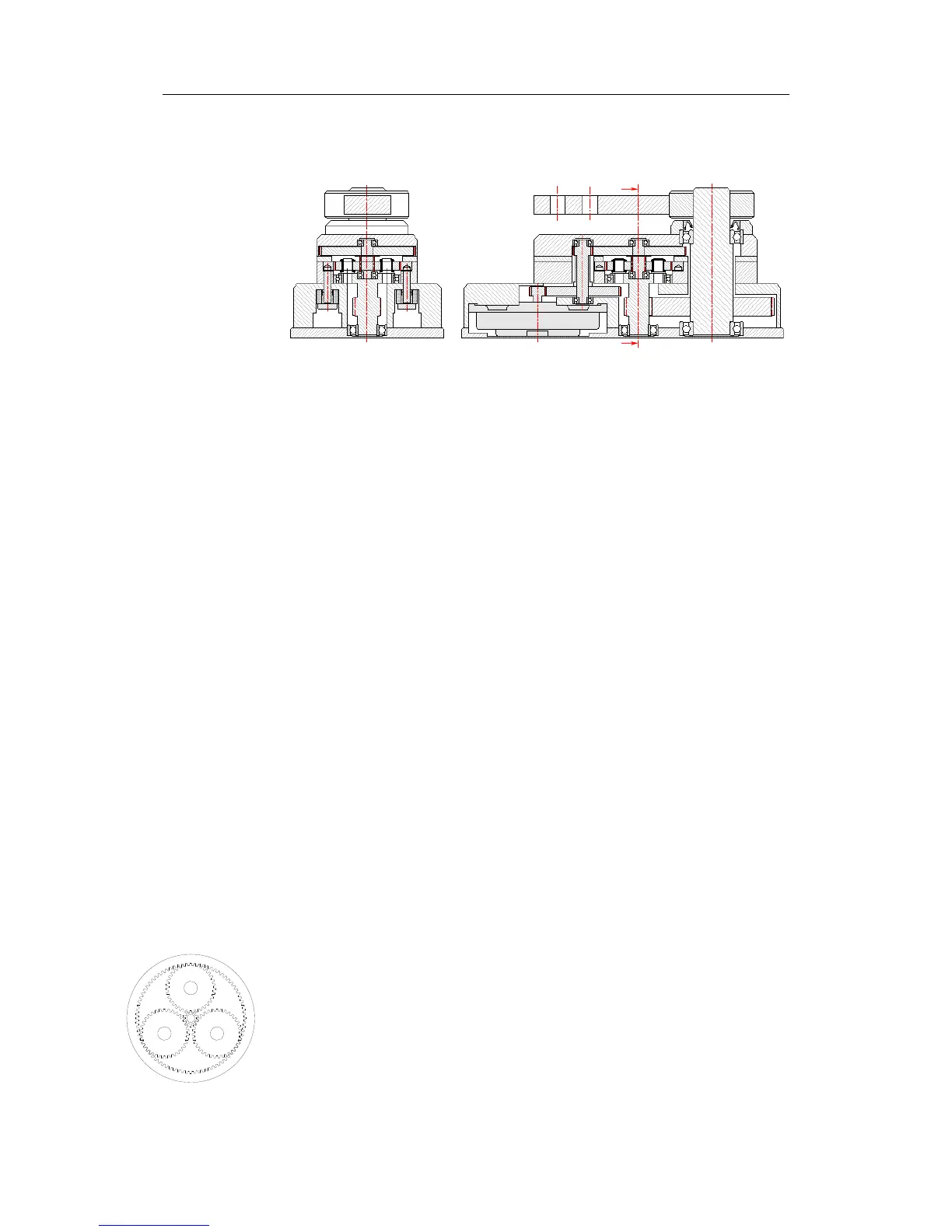

2.2 Planetary gearbox

To achieve a correct rudder travel speed (hard over time) the

electric motor has to be reduced in speed with a factor 750:1.

Some autopilot drive producers use a worm reduction box, but

the efficiency is extremely low as the gears rub each other. The

Simrad direct drive uses a combination of a planetary gearbox

and spur gear sets (one small gear and one big gear). The

planetary gearbox has following advantages:

Loading...

Loading...