Installation

20222303 / A 11

3 INSTALLATION

3.1 Mechanical mounting

The direct drive drives the rudder via a draglink to the existing

tiller lever or quadrant or via a separate tiller lever. The length of

the draglink and a separate tiller lever (if necessary) have to be

specified when ordering. See the Direct Drive Specification

Form (page 23) for available draglink lengths and tiller levers.

The draglink part numbers are listed on page 22.

The drive can be mounted behind or next to the rudderstock,

driving the rudder directly or in front of the pedestal driving the

rudder via the pedestal.

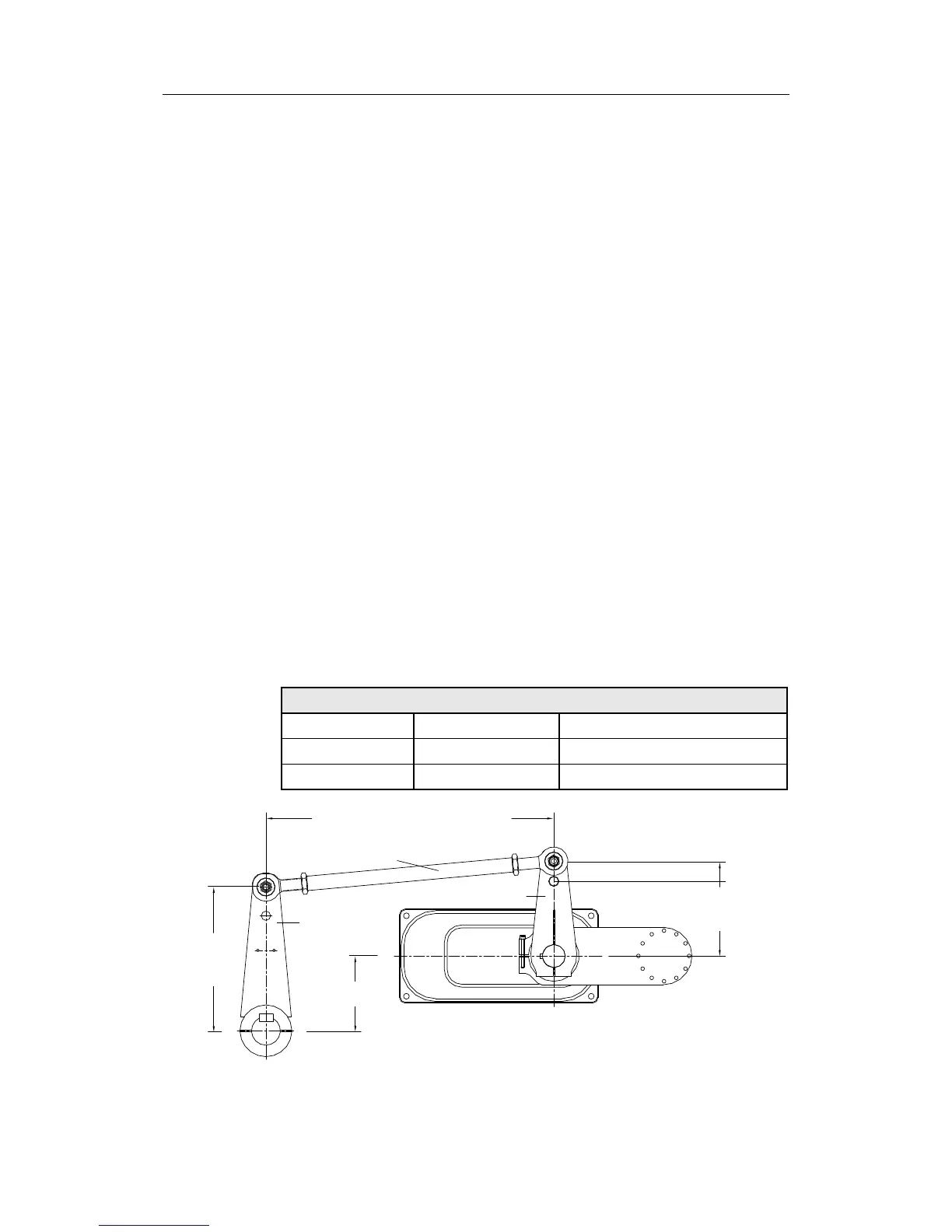

The direct drive com

es as standard with a 16 mm pin 165 mm from

the center of the output lever. The pin can be moved to the 130 mm

position from the center, but must be secured with Loctite.

The direct drive uses “wide angle geometry”. The result of this is

a 130° travel of the output lever and a 72° travel of the tiller

lever( see Figure 3-2). To achieve an equal travel of the drive at

port and starboard, the center point of the output lever needs an

offset to the rudderstock centre. The offset depends on the used

lever centers. Following table shows the correct offset distances:

Operating centers in mm valid for 72° (2x36°) rudder travel.

Output center Offset distance Tiller center

130 106 200

165 127 250

Offset

Tiller

center

Output

center

Min. 300 - max 2000 mm

165 mm

130 mm

Output lever

Tiller lever

Draglink

Figure 3-1 Mechanical mounting

Loading...

Loading...