( ADJUSTMENTS

))

U]

Needle

sidewise

movement

adjustment

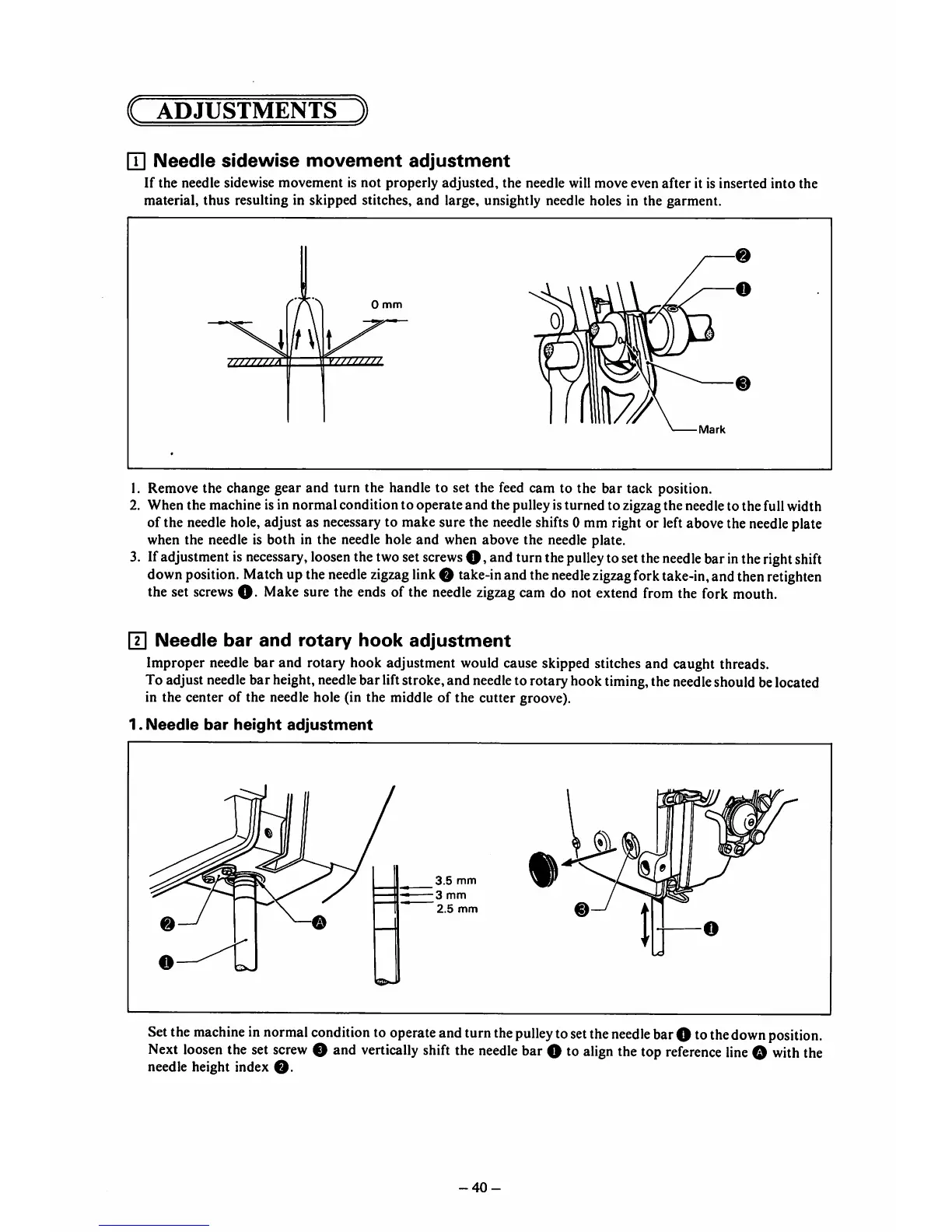

If the needle sidewise

movement

is

not

properly

adjusted,

the needle will move even

after

it is inserted

into

the

material, thus resulting in skipped stitches, and large, unsightly needle holes in the garment.

0

mm

o

0

Mark

1. Remove the change gear and turn the handle to set the feed cam to the bar tack position.

2. When the machine is in normal condition to operateand the pulleyisturned to zigzagthe needle to the full width

of the needle hole, adjust as necessary to make sure the needleshifts 0 mm right or left above the needleplate

when the needle is both in the needle hole and when above the needle plate.

3. If

adjustment

is

necessary,

loosen

thetwoset

screws

O»and turnthe

pulley

tosetthe

needle

barinthe

right

shift

down

position.

Match

upthe

needle

zigzag

link

O

take-in

andthe

needle

zigzag

fork

take-in,

and

then

retighten

the set

screws

O.

Make sure the ends of the

needle

zigzag

cam do not extend from the fork mouth.

|T|

Needle

bar

and

rotary

hook

adjustment

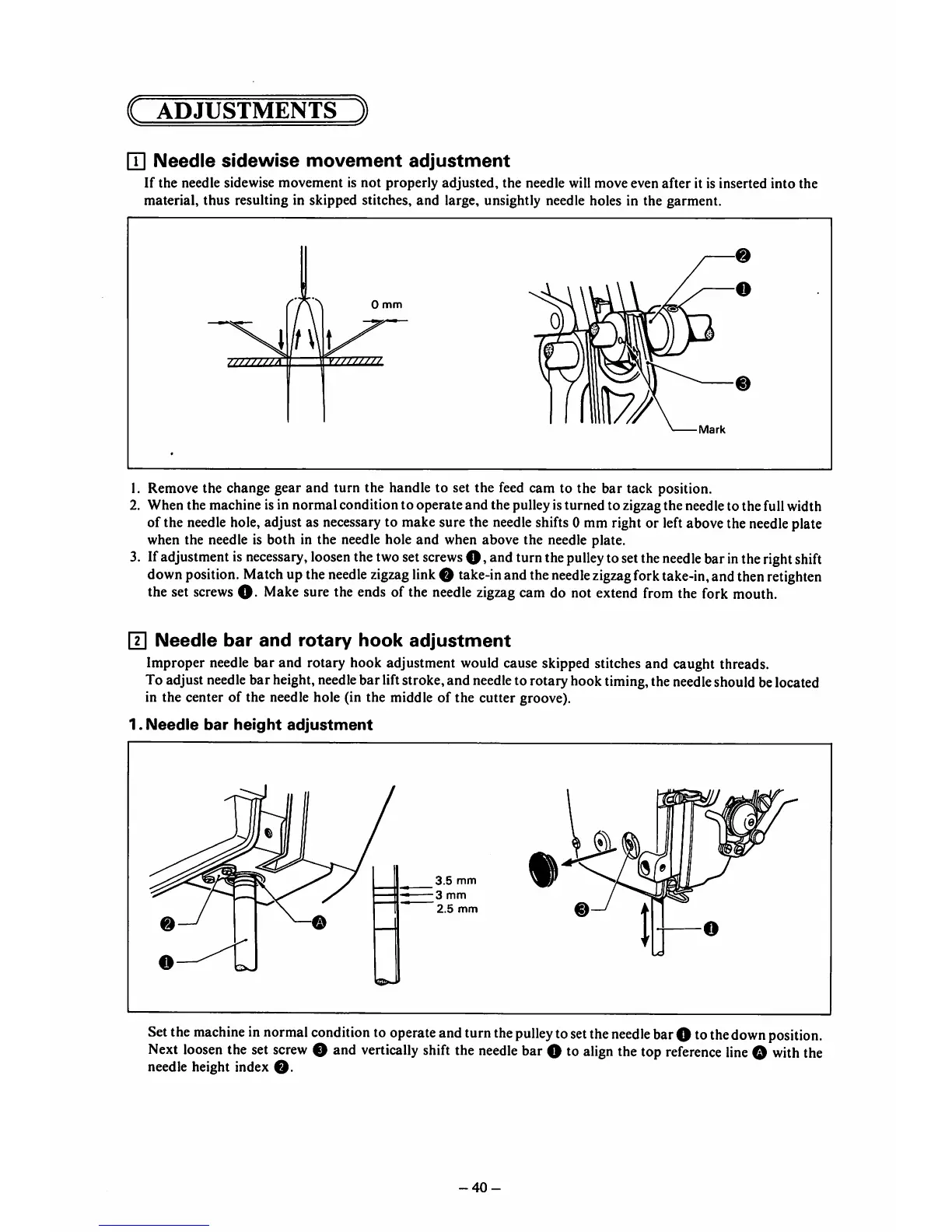

Improper needle

bar

and rotary hook adjustment would cause skipped stitches and caught threads.

To adjust needlebar height,needlebar liftstroke, and needleto rotary hook timing,the needleshould belocated

in the center of the needle hole (in the middle of the cutter groove).

1.

Needle

bar

height

adjustment

3.5

mm

;3 mm

2.5

mm

Setthe

machine

in

normal

condition

to

operate

andturnthe

pulley

to

set

the

needle

barO tothe

down

position.

Next

loosen

the set

screw

and vertically shift the

needle

bar O to alignthe top

reference

lineO withthe

needle height index

O-

40-

Loading...

Loading...