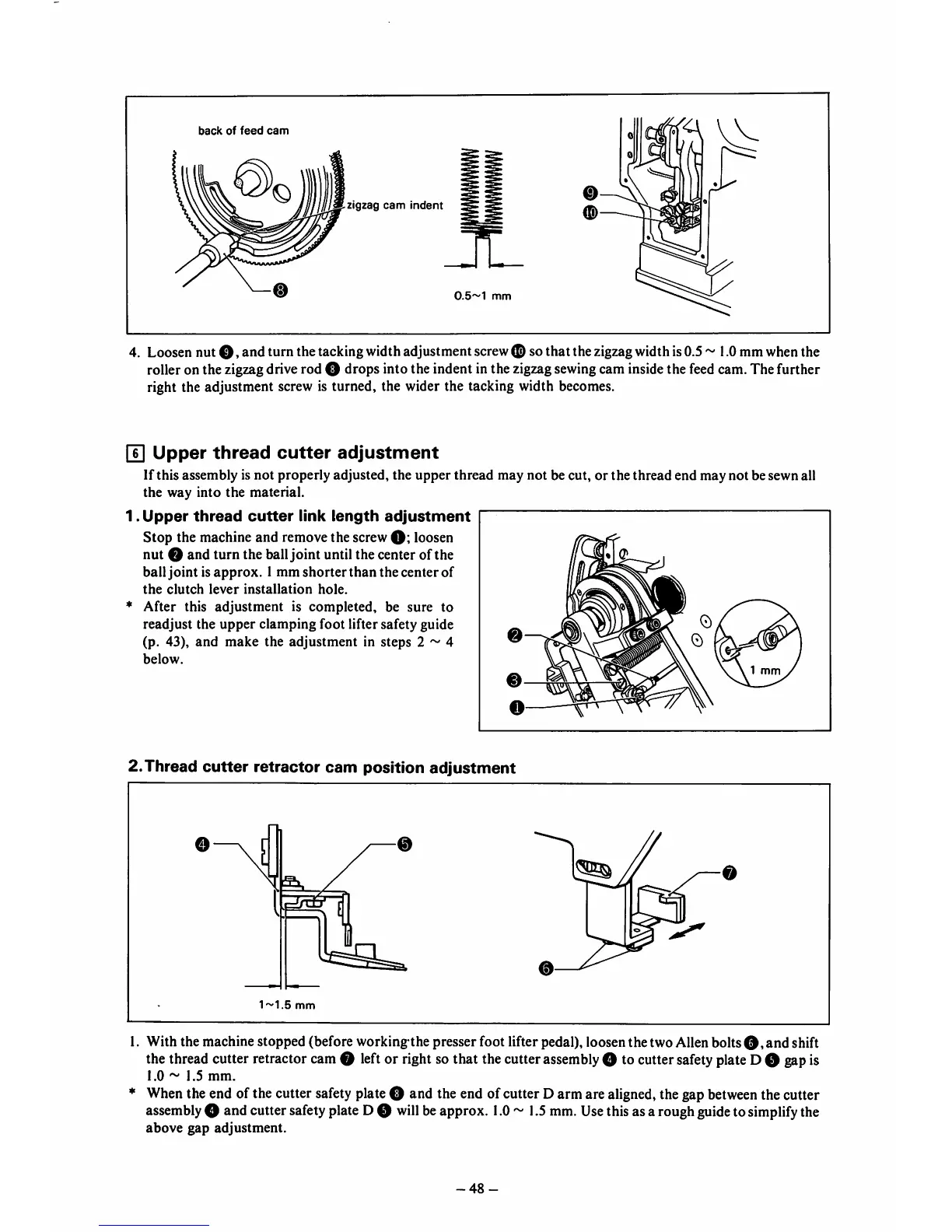

back

of

feed

cam

zigzag

cam

indent

0.5~1

mm

4. Loosen nut

O,

and turn thetackingwidthadjustment screw

(S)

so that the zigzagwidthis0.5 1.0mmwhenthe

roller on the zigzagdrive rod O drops into the indent in the zigzagsewingcam insidethe feedcam. The further

right the adjustment screw is turned, the wider the tacking width becomes.

U]

Upper

thread

cutter

adjustment

If this assembly is not properly adjusted, the

upper

thread

may not be cut, or the thread end may not be sewn all

the way into the material.

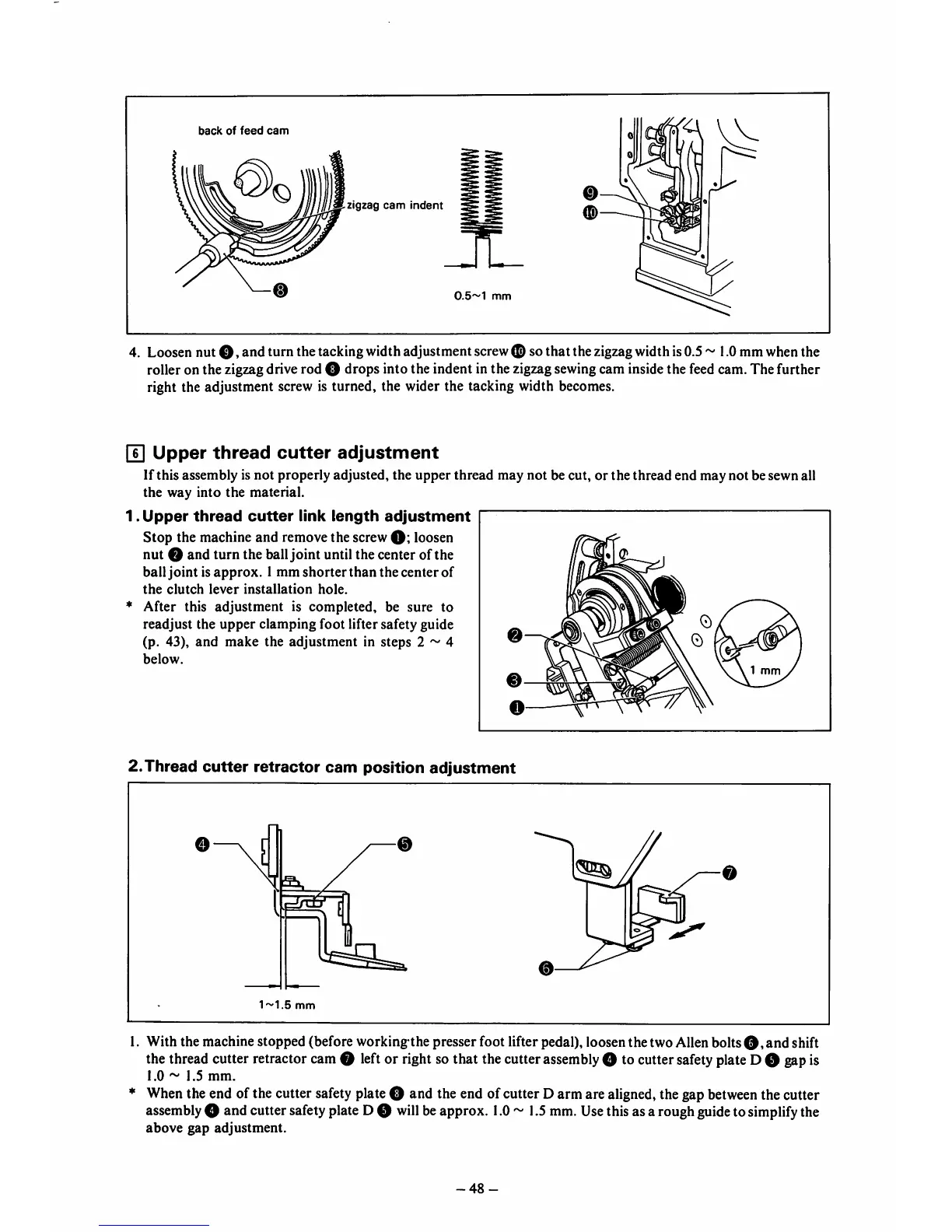

1.

Upper

thread

cutter

link

length

adjustment

Stop

the machine

and

remove the screw loosen

nut o and turn the balljoint until the center of the

ball joint is approx. 1mm shorterthan the centerof

the

clutch

lever

installation

hole.

♦

After this adjustment is completed, be sure to

readjust the upper clamping foot lifter safety guide

(p. 43),

and

make

the adjustment in steps 2 ~ 4

below.

2.Thread

cutter

retractor

cam

position

adjustment

0

1.5

mm

1. With the machine stopped (before working the presser foot lifter pedal), loosen the two Allen bolts

©,

and

shift

the threadcutter retractorcamo leftor rightso that thecutter

assembly

O to cutter

safety

plateD 0 gapis

1.0

~

1.5

mm.

♦

When

the end ofthe cutter

safety

plateO and the end ofcutter Darm are

aligned,

thegap

between

thecutter

assembly

O andcutter

safety

plateD0

will

beapprox.

1.0

~

1.5

mm.

Use

thisasa rough

guide

to

simplify

the

above

gap

adjustment.

-48-

Loading...

Loading...