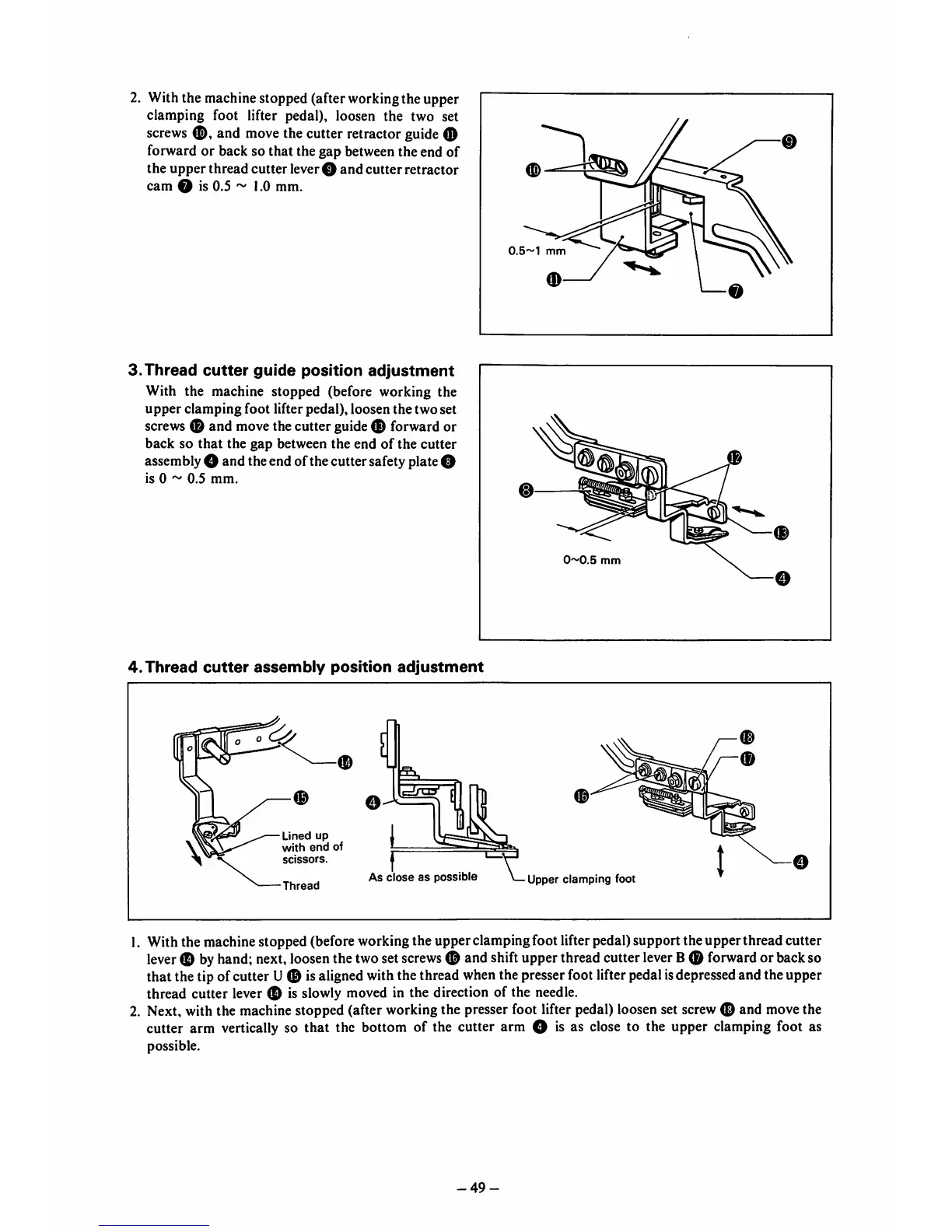

2. Withthe machinestopped (after workingthe upper

clamping foot lifter pedal), loosen the two set

screws

and

move the cutter retractor guide 0

forward or back so that the gap between the end of

the upperthread cutter lever O

and

cutter

retractor

cam O is 0.5 ~ 1.0 mm.

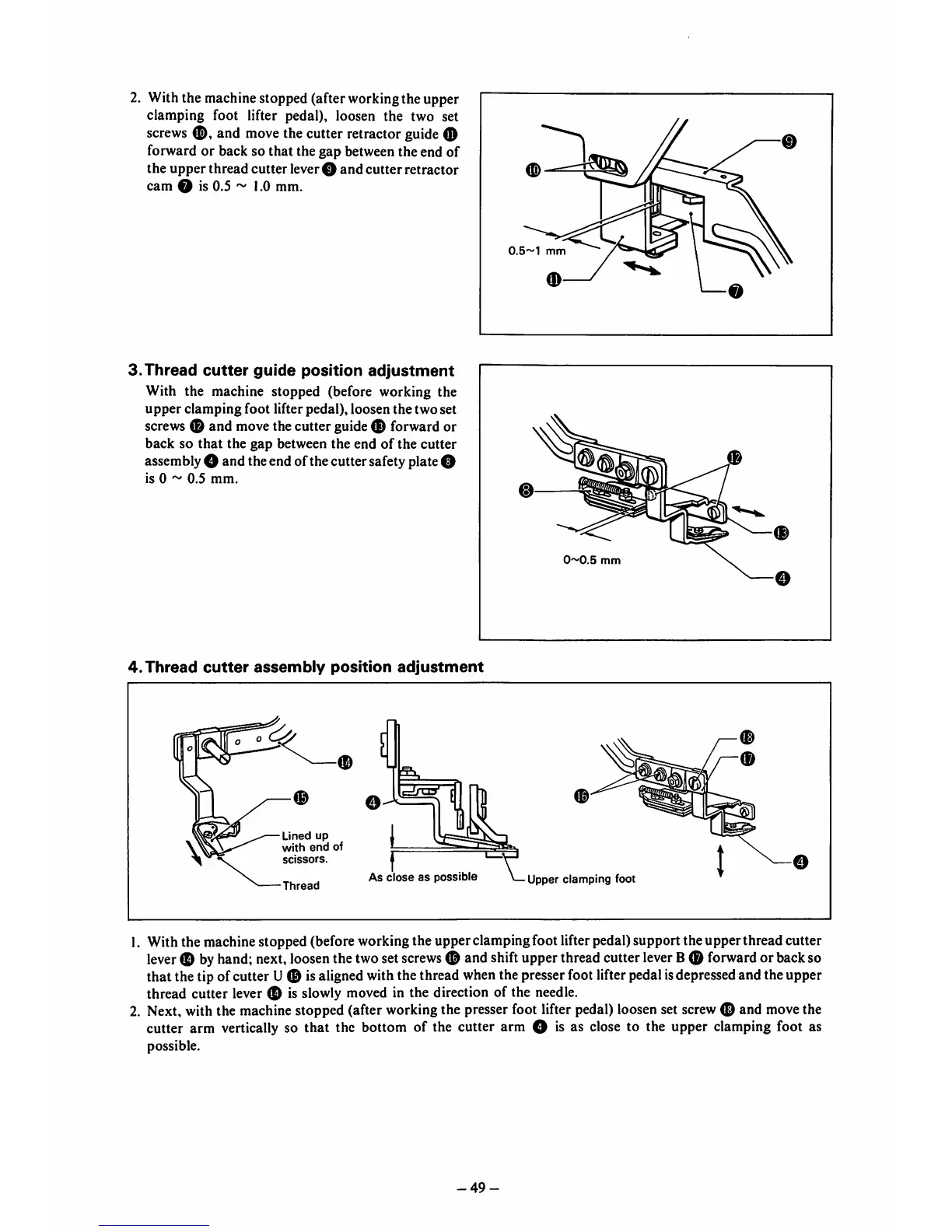

3.Thread

cutter

guide

position

adjustment

With the machine stopped (before working the

upper

clamping

foot

lifter pedal), loosen

the

two

set

screws 0 and movethe cutter guide 0 forward or

back

so

that

the

gap

between the end

of

the

cutter

assemblyO and theend ofthecutter safetyplateO

is 0 ~

0.5

mm.

/—®

0.5~1

mm

0

^ \

—0

I

0~0.5

mm

4.

Thread

cutter

assembly

position

adjustment

2.

0

Lined

up

with

end

of

scissors.

Thread

O

c=DTP'

As

close

as

possible

Upper clamping foot

With the machine stopped (before working the upper clamping foot lifter pedal) support the upperthread cutter

lever

0 byhand;next,

loosen

thetwoset

screws

0 and shiftupperthreadcutter

lever

B0

forward

or backso

that the tip of cutter U© is aligned with the thread when the presserfoot lifterpedalisdepressedand the upper

thread cutter lever 0 is slowly moved in the direction of the needle.

Next, with the machinestopped (after workingthe presserfoot lifter pedal) loosenset

screw

0 and movethe

cutter arm vertically so that the bottom of the cutter arm O is as

close

to the upper clamping foot as

possible.

-49-

Loading...

Loading...