im

Adjustment

of

feed

cam

segment

When theseadjustments are not complete,the timingfor the bar tackingperiodsand thetenison releasingwillbe

adversely affected, resulting in

thread

breakage

or

uneven stitches.

1.

Position

adjustment

of

stop

cam

segment

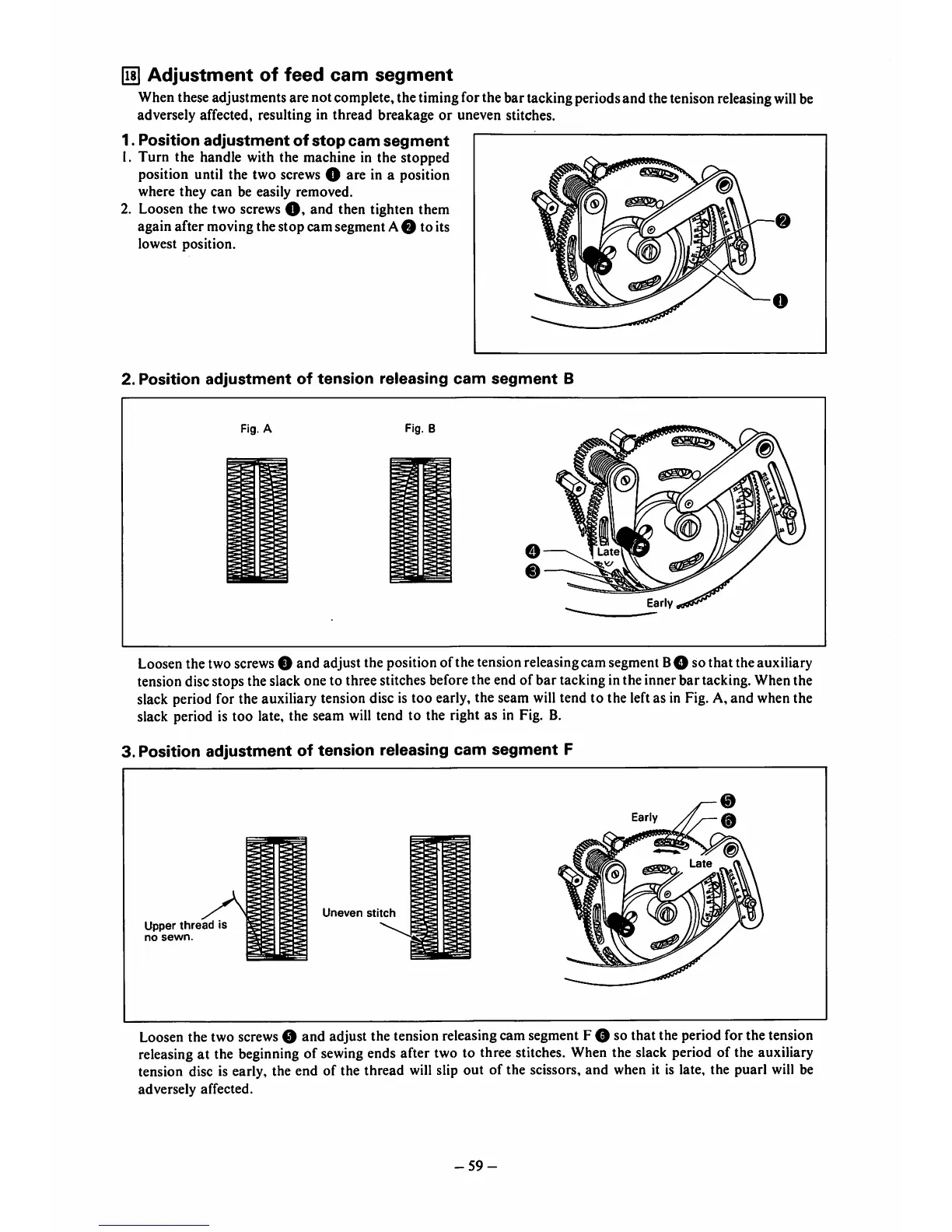

1.

Turn

the handle with the machine in the stopped

position until the two screws O are in a position

where

they

can

be easily removed.

2. Loosen the two screws and then tighten them

again after moving the stop cam segment AO to its

lowest

position.

2.

Position

adjustment

of

tension

releasing

cam

segment

B

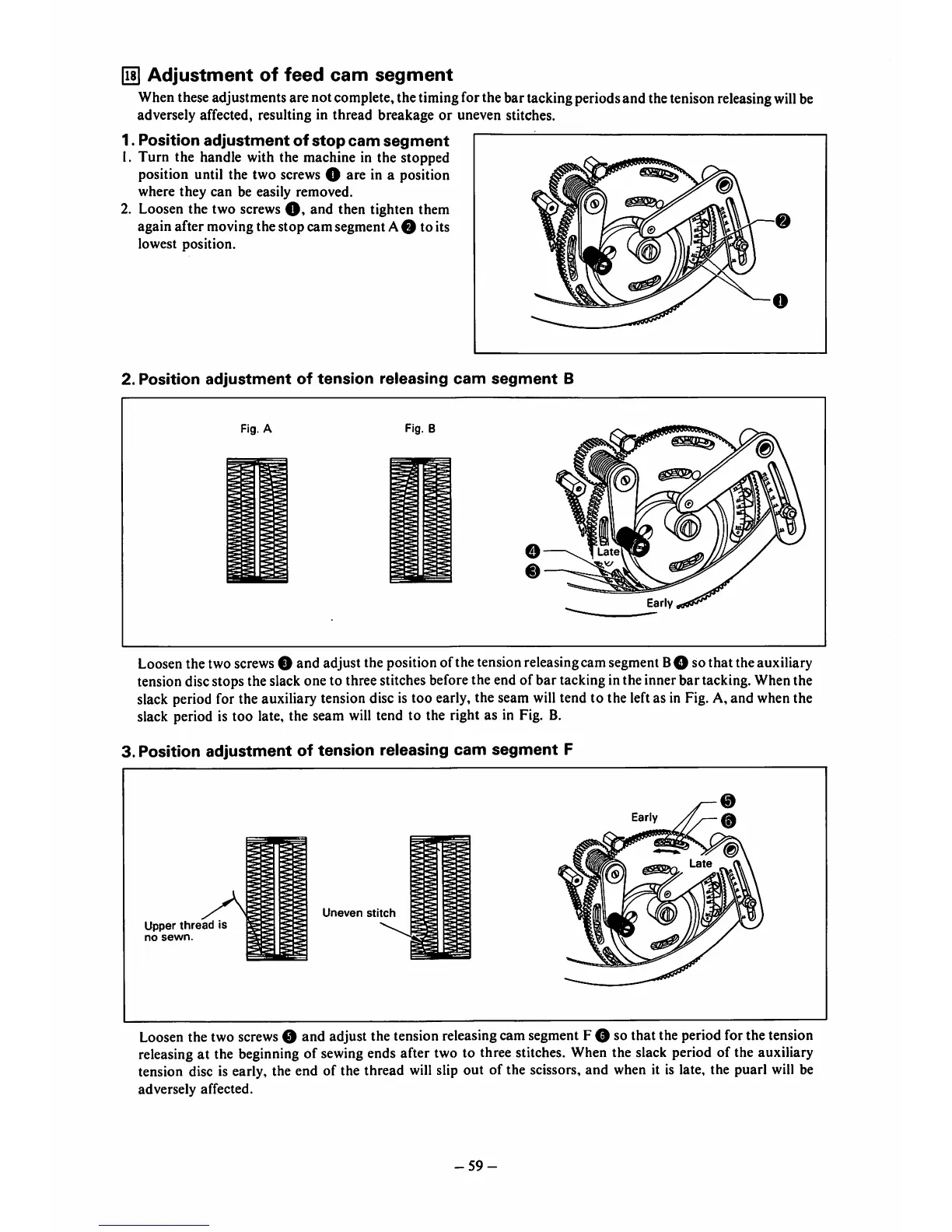

Loosen the two screwsO and adjust the position of the tension releasingcam segment

BO

so that the auxiliary

tension disc stops the slack one to three stitches before the end of bar tacking in the inner bar tacking. When the

slack period for the auxiliary tension disc is too early, the seam will tend to the left as in Fig. A, and when the

slack period is too late, the seam will tend to the right as in Fig. B.

3.

Position

adjustment

of

tension

releasing

cam

segment

F

Upper

thread

is

no

sewn.

Uneven

stitch

Loosen the two screws0 and adjust the tension releasingcam segment F O so that the period for the tension

releasingat the beginning of sewing ends after two to three stitches. When the slack period of the auxiliary

tension disc is early, the end of the thread will slip out of the scissors, and when it is late, the puarl will be

adversely affected.

-59-

Loading...

Loading...