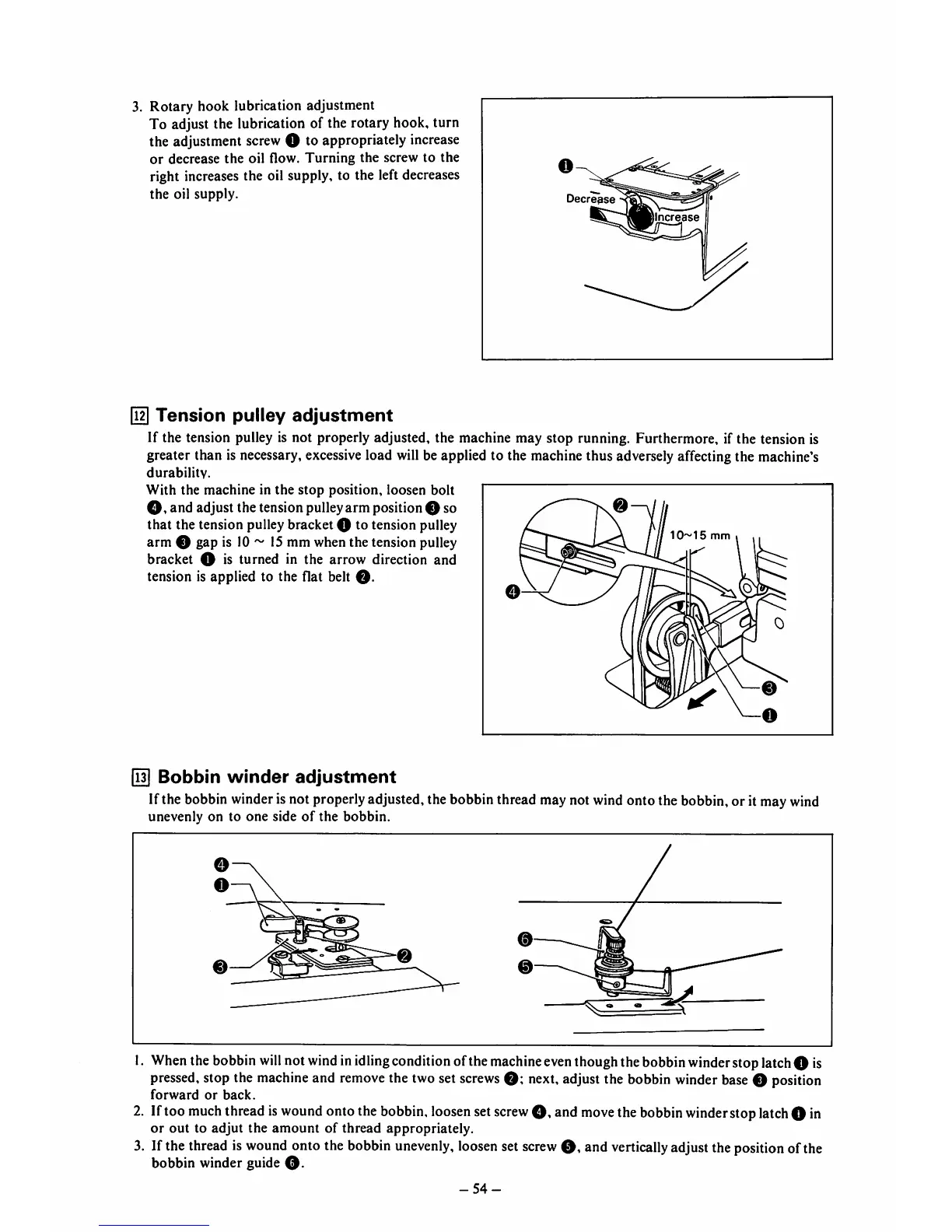

Rotary hook lubrication adjustment

To adjust the lubrication of the rotary hook, turn

the adjustment

screw

O to appropriatelyincrease

or

decrease

the

oil flow.

Turning

the

screw to

the

right increases the oil supply, to the left decreases

the

oil supply.

Decrease

«

^^~~Wttlncrease

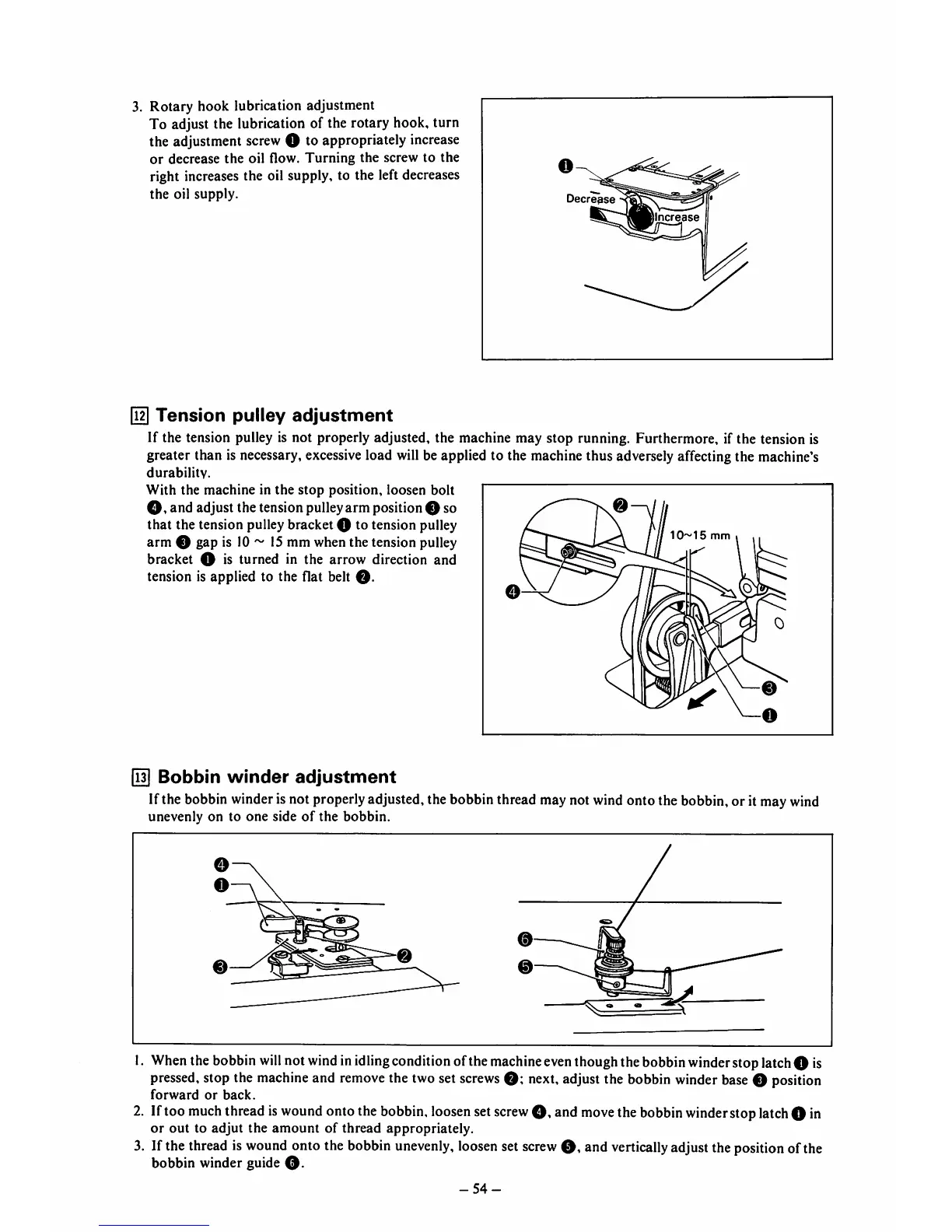

[I2]

Tension

pulley

adjustment

If the tension pulley is not properly adjusted, the machine may stop running. Furthermore, if

greater than is necessary,excessiveload will be applied to the machine thus adversely affecting

durability.

With the machine in

the

stop

position, loosen bolt

^nd adjust the tension pulley

arm

position O so

that the tension pulleybracket O to tension pulley

arm O gap is

10

~

15

mm whenthe tension pulley

bracket O is turned in the

arrow

direction

and

tension is applied to the flat belt

O.

lb

mm

the

tension

is

the

machine's

i]

Bobbin

winder

adjustment

Ifthe

bobbin

winder

isnot properly adjusted,the bobbinthread maynot

wind

ontothe bobbin,or it may

wind

unevenly on to

one

side

of

the

bobbin.

1.

When

the bobbin

will

not

wind

inidlingconditionofthe

machine

eventhoughthebobbinwinderstop latchO is

pressed,

stopthe

machine

and

remove

the

two

set

screws

O;

next,

adjust

the

bobbin

winder

base

O

position

forward

or

back.

2. Iftoo

much

thread iswoundonto the bobbin,loosenset

screw

and

move

the bobbinwinderstoplatchO in

or

out

to

adjut

the

amount

of thread appropriately.

3. Ifthe

thread

is

wound

onto the

bobbin

unevenly,

loosen

set

screw

0,

and

vertically

adjusttheposition ofthe

bobbin winder guide

O.

-54-

Loading...

Loading...