[T]

Thread

breakage

detection

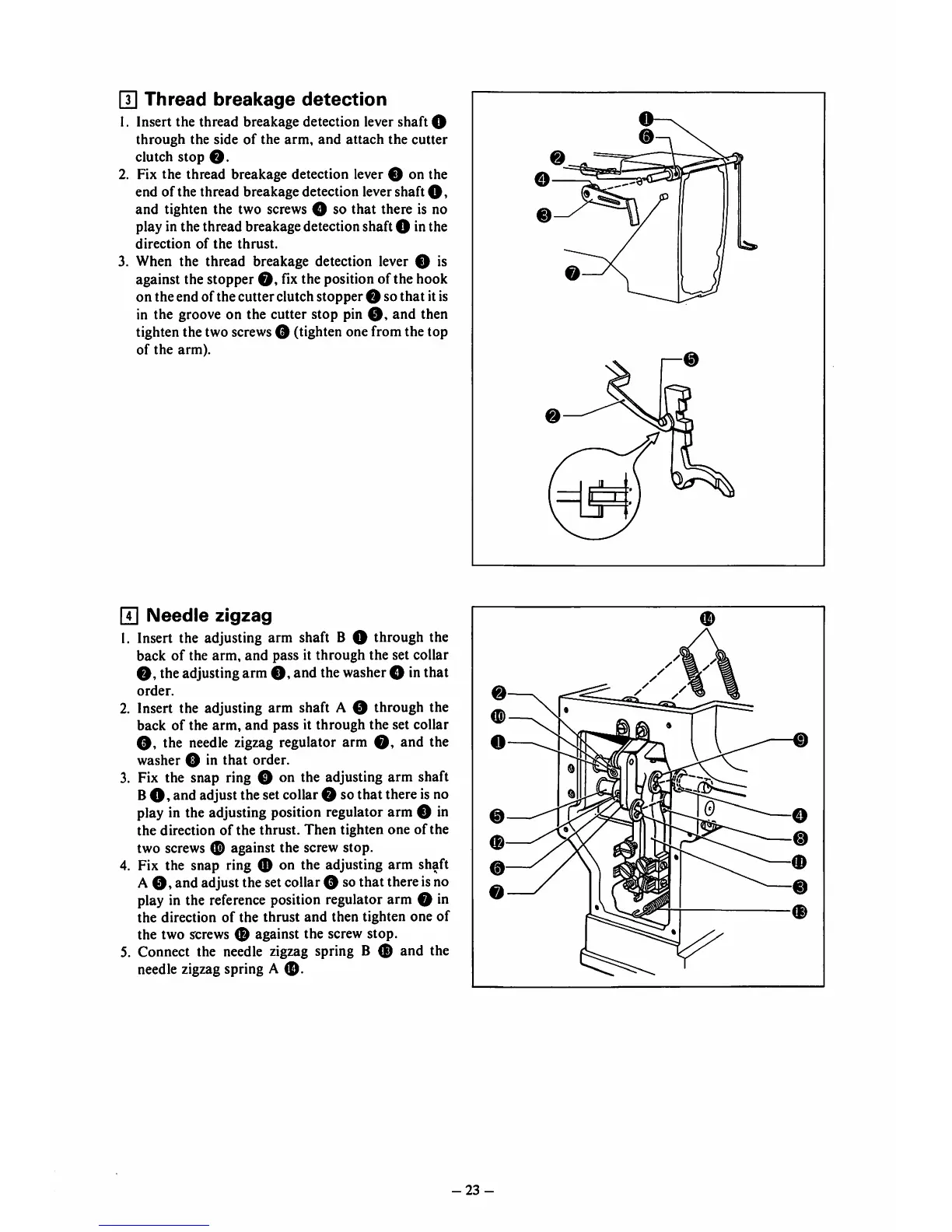

1. Insert the thread breakage detection lever shaft O

through

the side

of

the

arm,

and

attach

the

cutter

clutch stop

O.

2. Fix the thread breakage detection lever O on the

end

of

the

thread

breakage detection lever shaft

and tighten the two screws O so that there is no

play in the thread breakagedetectionshaft O inthe

direction

of

the

thrust.

3. When the thread breakage detection lever O is

against the stopper fix the position of the hook

on theend of the cutter clutch stopper O so that it is

in the groove on the cutter stop pin

0,

and then

tighten the two screwsO (tighten one from the top

of

the

arm).

[T|

Needle

zigzag

1.

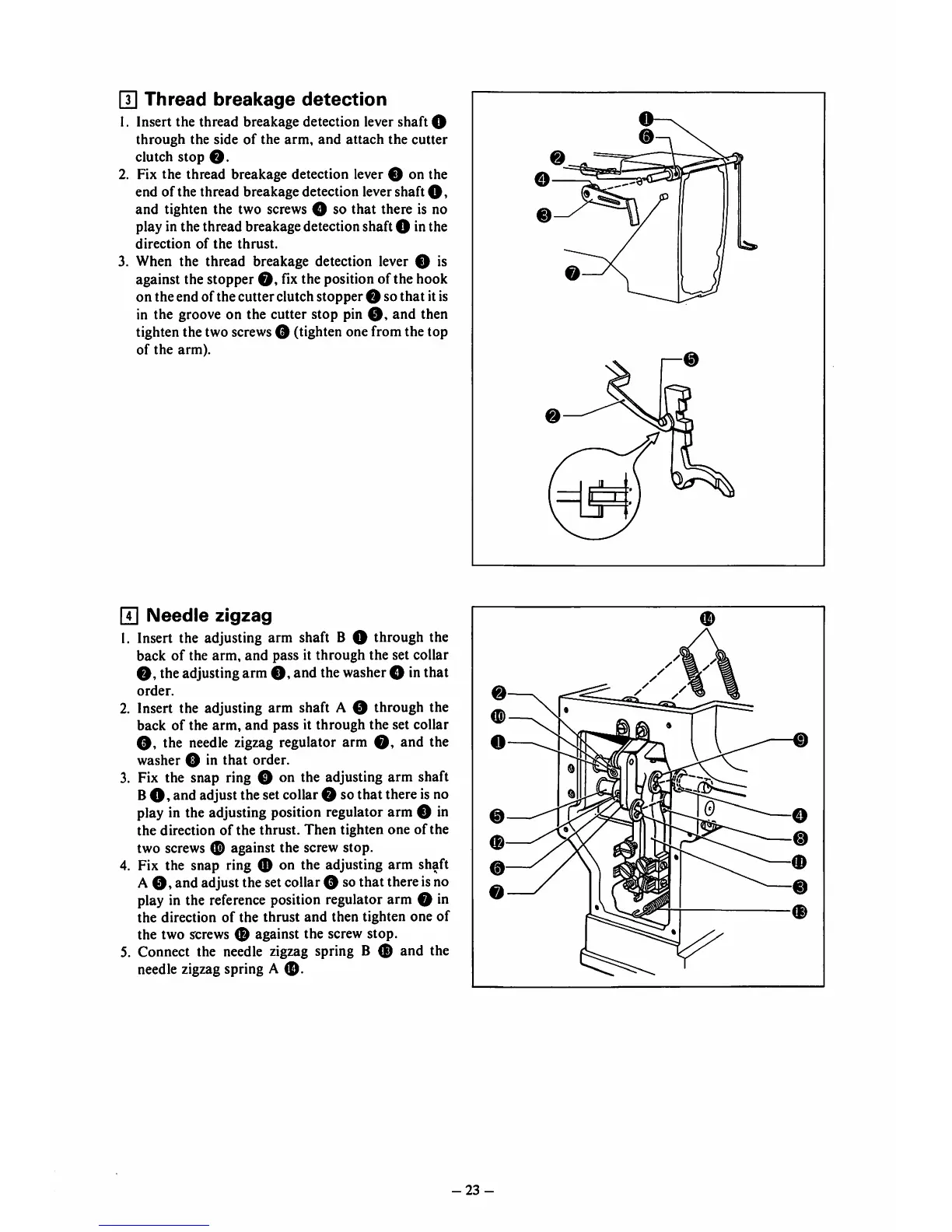

Insert the adjusting arm shaft B O through the

back

of

the

arm,

and

pass it

through

the

set

collar

0,

the adjusting arm

0,

and the washer0 in that

order.

2. Insert the adjusting arm shaft A 0 through the

back

of

the

arm,

and

pass it

through

the

set collar

0,

the needle zigzag regulator arm

0,

and the

washer 0 in that order.

3. Fix the snap ring 0 on the adjusting arm shaft

B

0,

and adjustthe setcollar0 so that there isno

play in the adjusting position regulator arm 0 in

the direction

of

the thrust.

Then

tighten one of the

two screws 0 against the screw stop.

4. Fix the snap ring 0 on the adjusting arm shaft

A0,

and adjust the set collar 0 so that there isno

play in the

reference

position regulatorarm 0 in

the

direction

of

the

thrust

and

then

tighten

one

of

the two screws 0 against the screw stop.

5. Connect the needle zigzag spring B 0 and the

needle zigzagspring A

0.

0

-23-

0

0

0

Loading...

Loading...