PRE-OPERATION INSPECTION

1323RE&1623RE Operation Manual 5-3 © Jun. 2021

Perform the following procedure with the platform

retracted and machine off:

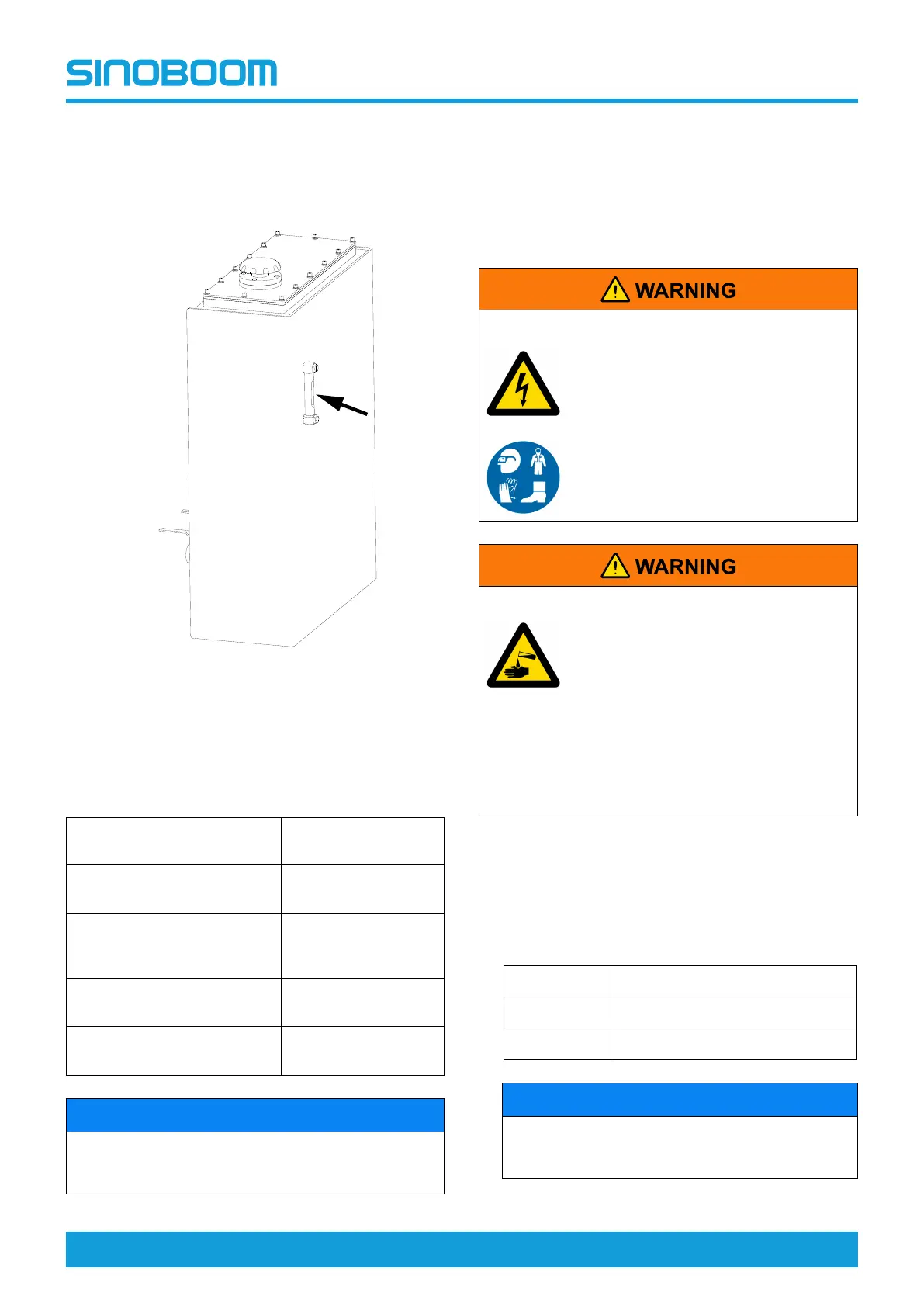

1. Visually inspect on the hydraulic tank side to be

sure the hydraulic oil level is whithin the marking

range of sight gauge.

Figure 5-1

2. Ensure the tank body and ports are free of leakage.

3. Add hydraulic oil as needed. Never overfill the tank.

Table 5-1

CUSTOMER

REQUIREMENTS

HYDRAULIC OIL

MARK

Normal-temperature region

0°C to 40°C (32°F to 104°F)

L-HM46

Cold region

-25°C to 25°C (-13°F to 77°

F)

L-HV32

High-temperature region

greater than 40°C (104°F)

L-HM68

Extremely cold region

less than -30°C (-22°F)

Special programmes

need to be identified.

NOTICE

Different hydraulic oils can be added according to

customer requirements upon factory delivery, but

cannot be mixed.

INSPECTING THE BATTERY

The condition of the battery affects the performance of

the machine. Improper levels of battery electrolyte or

damaged cable and wiring may harm battery parts and

may pose dangerous conditions.

ELECTROCUTION HAZARD

• Contact with live circuits may

cause death or serious injury.

Always wear goggles, protective

gloves and protective clothing.

• Remove all rings, watches or

other jewelry

CHEMICAL BURN HAZARD

• Avoid battery acid spillage or

contact with unprotected skin. If

the battery acid comes into

contact with the skin, wash it

immediately with plenty of water

and seek medical attention

immediately.

• In case of battery acid spillage,

use water mixed with baking soda

to neutralize the acid.

• Check the battery level. The discharged capacity

shall not exceed 80% of the total capacity of the

battery. Charge the battery immediately after each

discharging.

• Ensure the battery cells are wired reliably with the

locking nuts torqued to the specifications as below:

Nut type Torque

M8 9~11Nm (6.6~8.1ft-lb)

M10 18~23Nm (13.2~17ft-lb)

NOTICE

Improper connection may cause reduced

performance, damaged terminals, fusions and

even fires.

Loading...

Loading...