9. Faults Page 26

EN

9. Faults

Table 6 provides an overview of possible

malfunctions and their causes. Contact the Service

department of SKF Lubrication Systems Germany

AG if you cannot remedy the malfunction.

Danger!

Performing work on an energized pump or

product may result in serious injury or

death. Assembly, maintenance, and repair

work may only be performed on products

that have been de-energized by qualified

technical personnel. The supply voltage

must be switched off before opening any

of the product's components.

Danger!

Centralized lubrication systems are

pressurized during operation. Centralized

lubrication systems must therefore be

depressurized before starting assembly,

maintenance or repair work, or any

system modifications or system repairs.

Dismantling of the product or individual

parts thereof within the statutory warranty

period is not permitted and voids any

claims.

All assembly, maintenance and repair work

beyond this scope must be performed by

the Service department of SKF Lubrication

Systems Germany AG.

Only original spare parts from SKF

Lubrication Systems Germany AG may be

used. Unauthorized alterations to products

and the use of non-original spare parts

and accessories are not permitted.

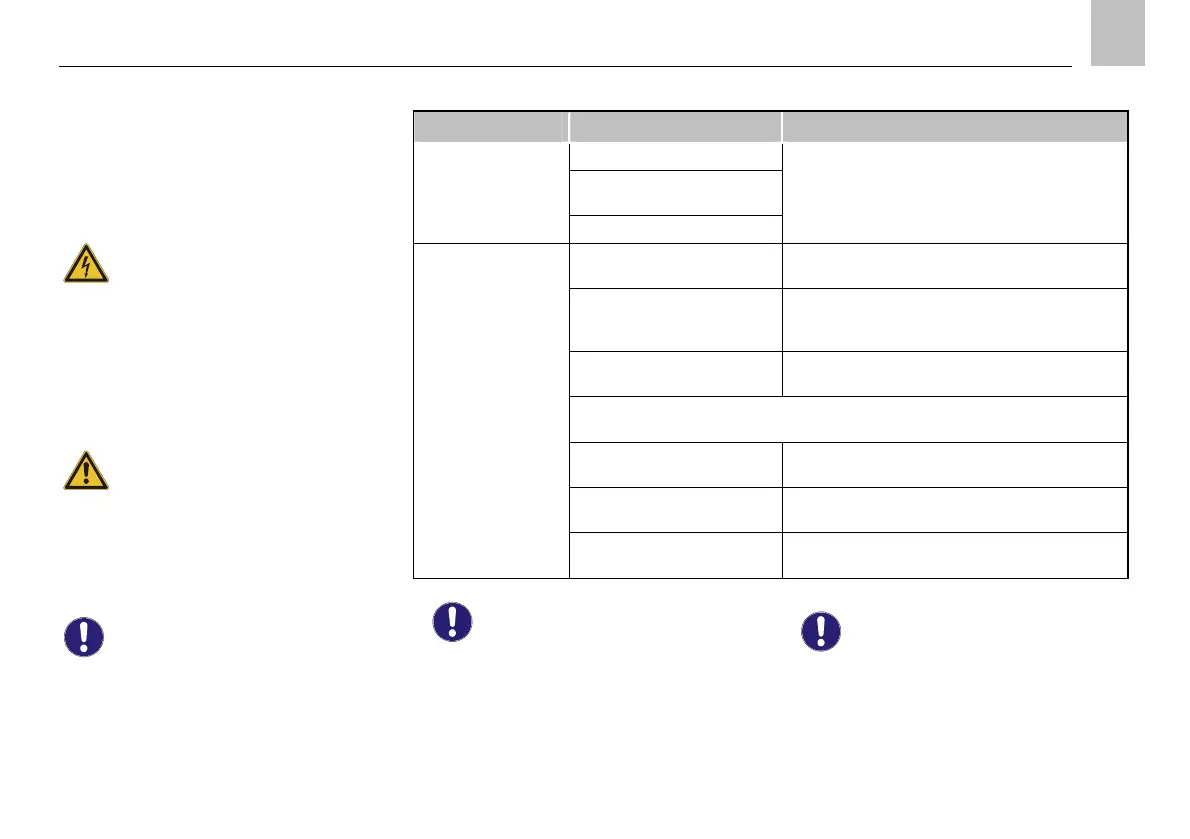

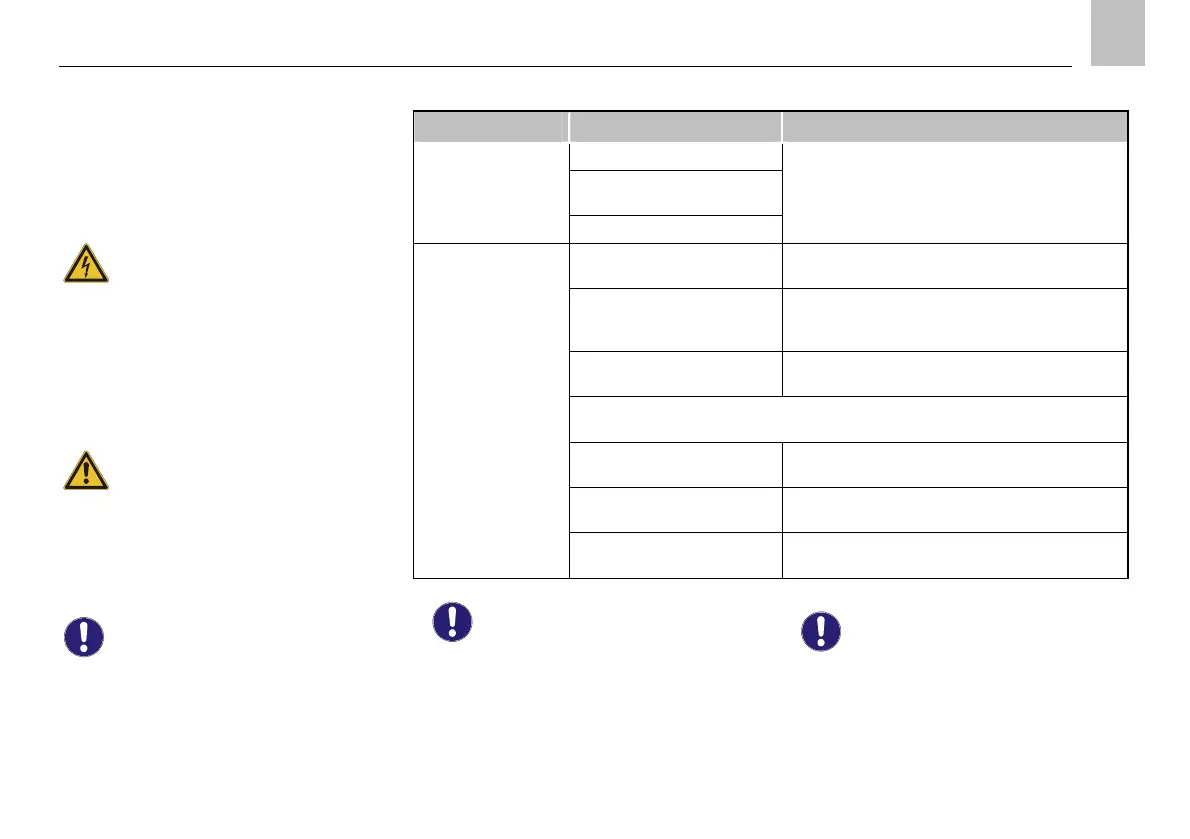

Table 6. Fault analysis and rectification

Malfunction Possible cause Rectification

Driver pin is broken

Seals in the actuating cylinder

are defective

Power transmission

from the actuating

mechanism to the

piston pump is

interrupted

Return spring is broken

Disassemble the piston pump in observance of the

safety instructions and replace the broken components.

Too little lubricant in lubricant

reservoir

Top up lubricant; check float switch, if installed

Wrong lubricant Remove lubricant from entire system and dispose of

lubricant properly; fill system with suitable lubricant

and vent system.

Air in the system Vent the system until lubricant without bubbles

discharges at the lubrication points.

For all other work, relieve pressure in the centralized lubrication system and the

actuating cylinder on pneumatically or hydraulically actuated piston pumps.

Pressure regulating valve does

not work

Check the pressure regulating valve for contamination

and damage, clean or replace as necessary.

Pressure relief valve does not

close

Check the pressure relief valve for contamination and

damage, clean or replace as necessary.

Piston pump does not

deliver medium

No pressure build-up

Discharge or suction valves do

not close.

Remove and inspect the valves, clean or replace as

necessary.

Loading...

Loading...