Page 10

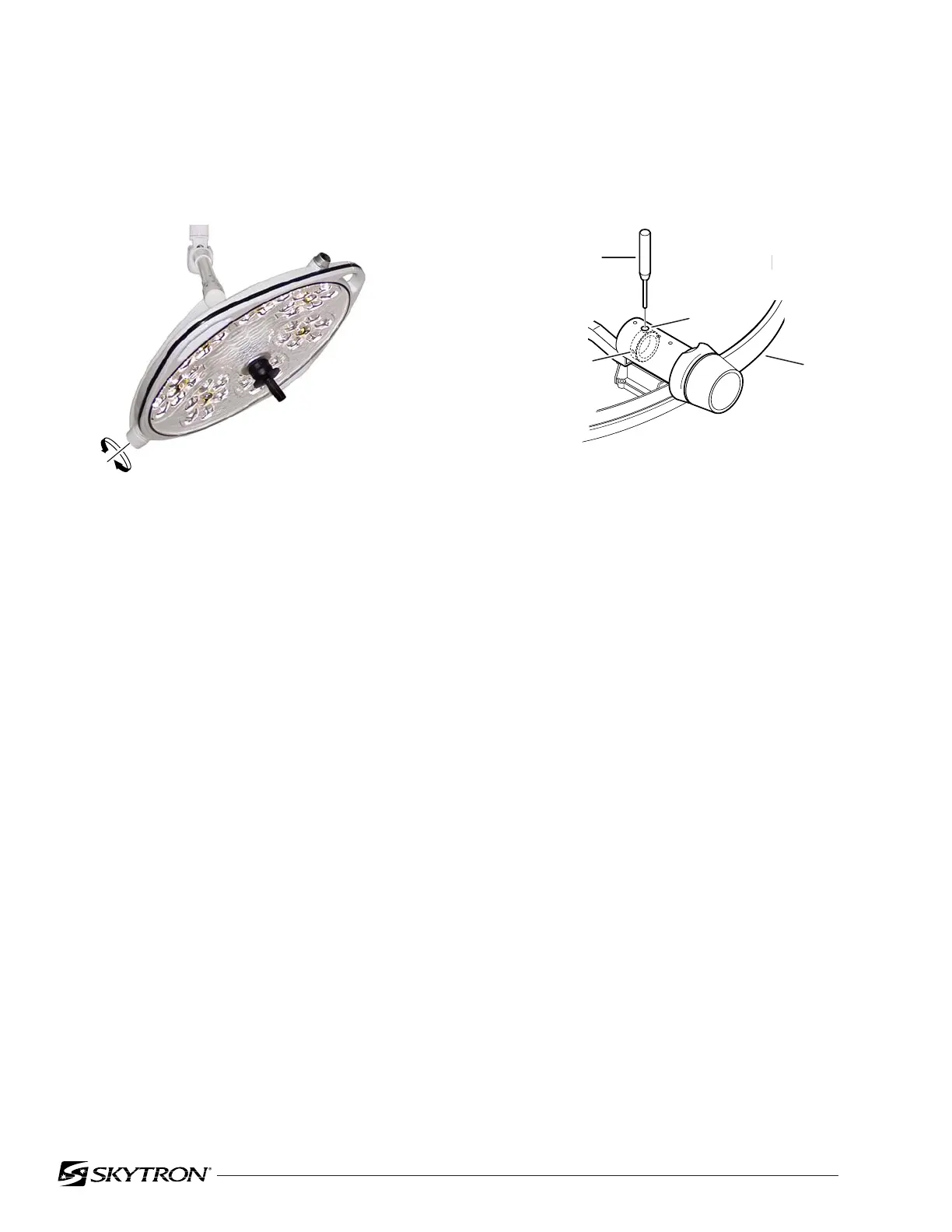

Figure 2-3. Lighthead Pitch Adjustment

d. Rotate the lighthead until a hole is visible and

insert a pin punch into the hole in the adjustment

nut.

e. With the nut held captive with the pin punch,

rotate the lighthead clockwise to increase the fric-

tion or counterclockwise to decrease the friction.

f. Remove pin punch and check adjustment.

Tighten set screws and replace top cover when

adjustment is complete.

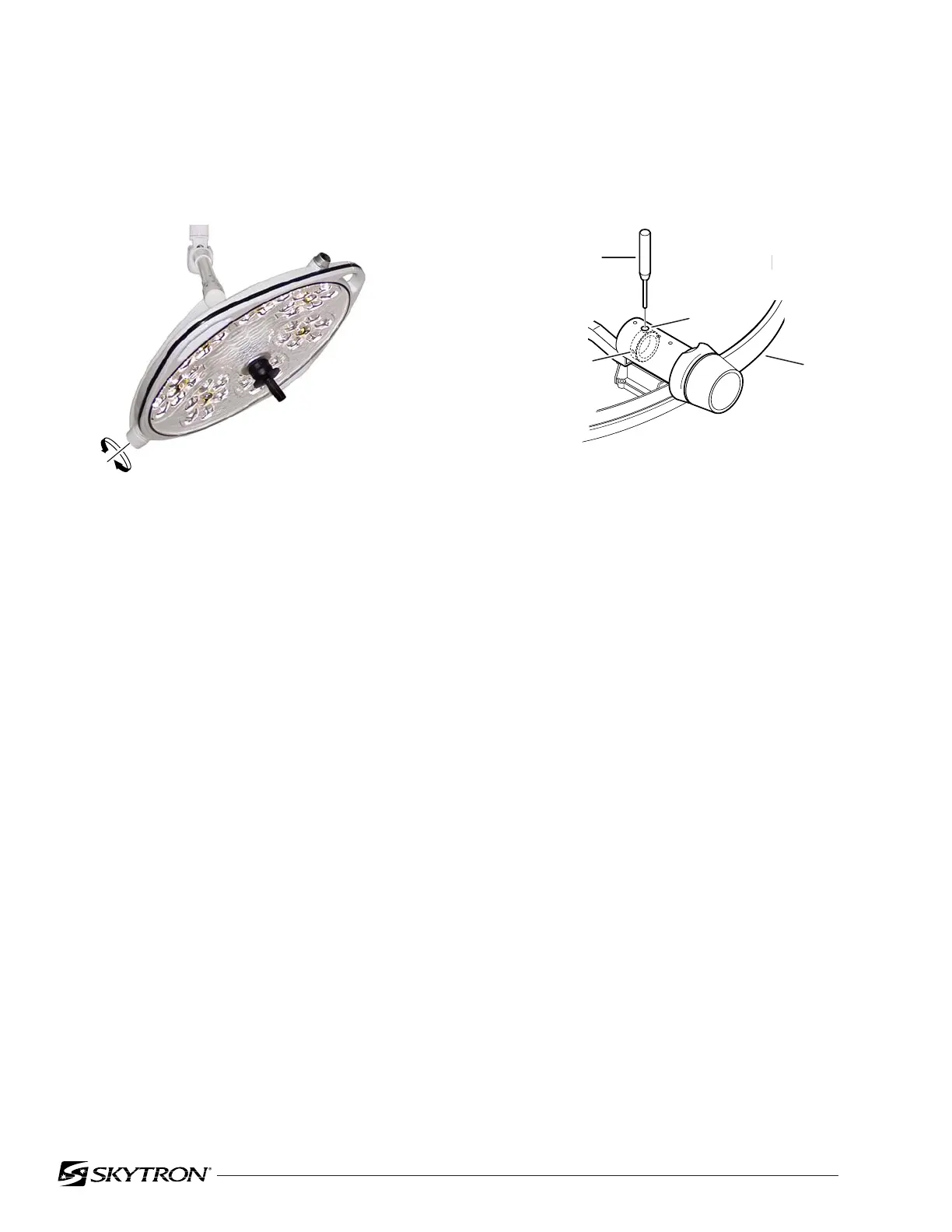

Figure 2-2. Lighthead Pitch

b. The lighthead should move freely yet main-

tain its position without drifting. If an adjustment is

required, remove the top cover, refer to figure 2-3

and proceed as follows:

c. Rotate the lighthead until an allen set screw

is visible through the adjustment hole. Loosen the

set screw, rotate the lighthead 180° and loosen the

second set screw.

2-2. Lighthead Pitch Adjustment

a. Check the pitch axis tension of each lighthead

by moving it through its full range of motion. See

figure 2-2.

A

PIN PUNCH

HOLE

YOKE

SET

SCREW (2)

Loading...

Loading...