Page 12

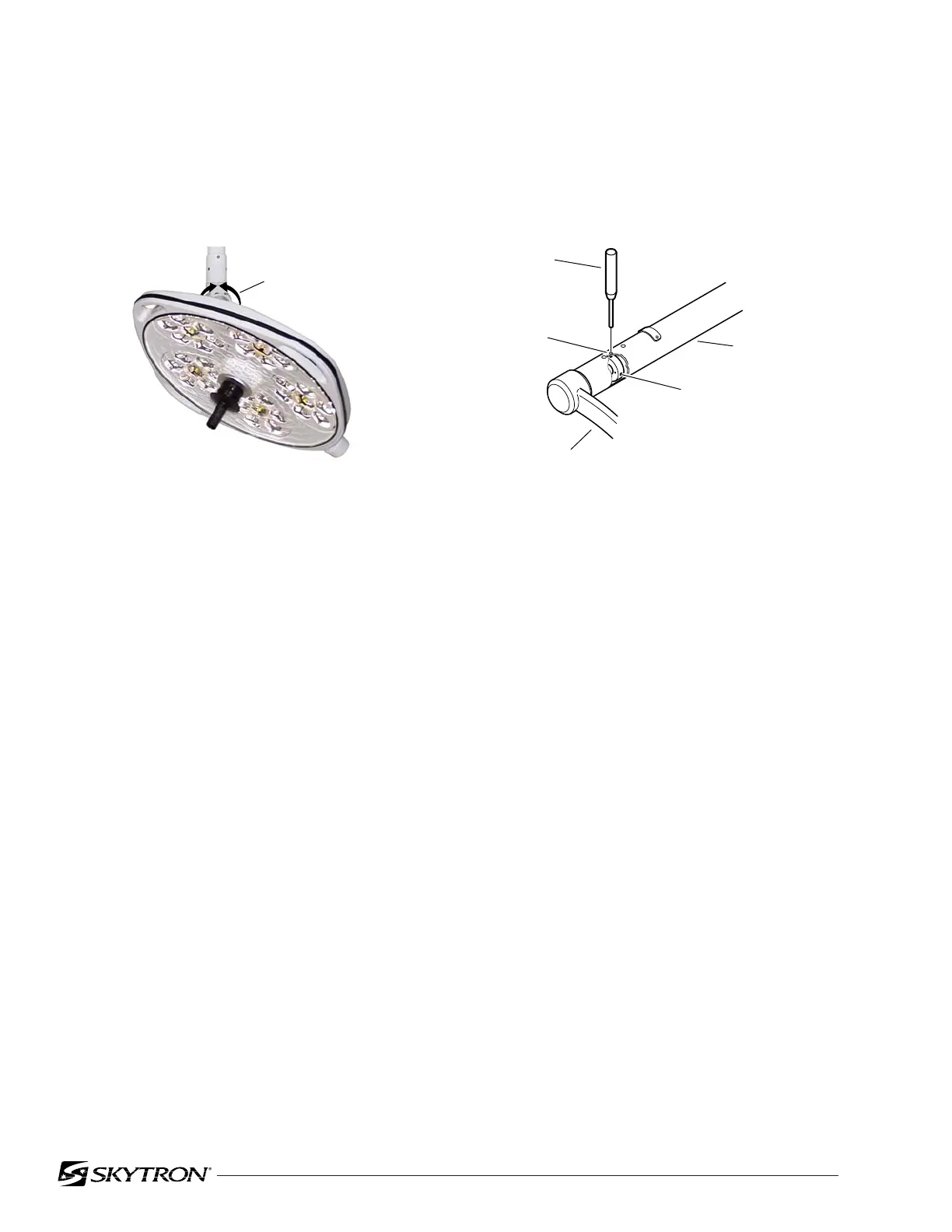

Figure 2-6. Model 5 Lighthead Roll

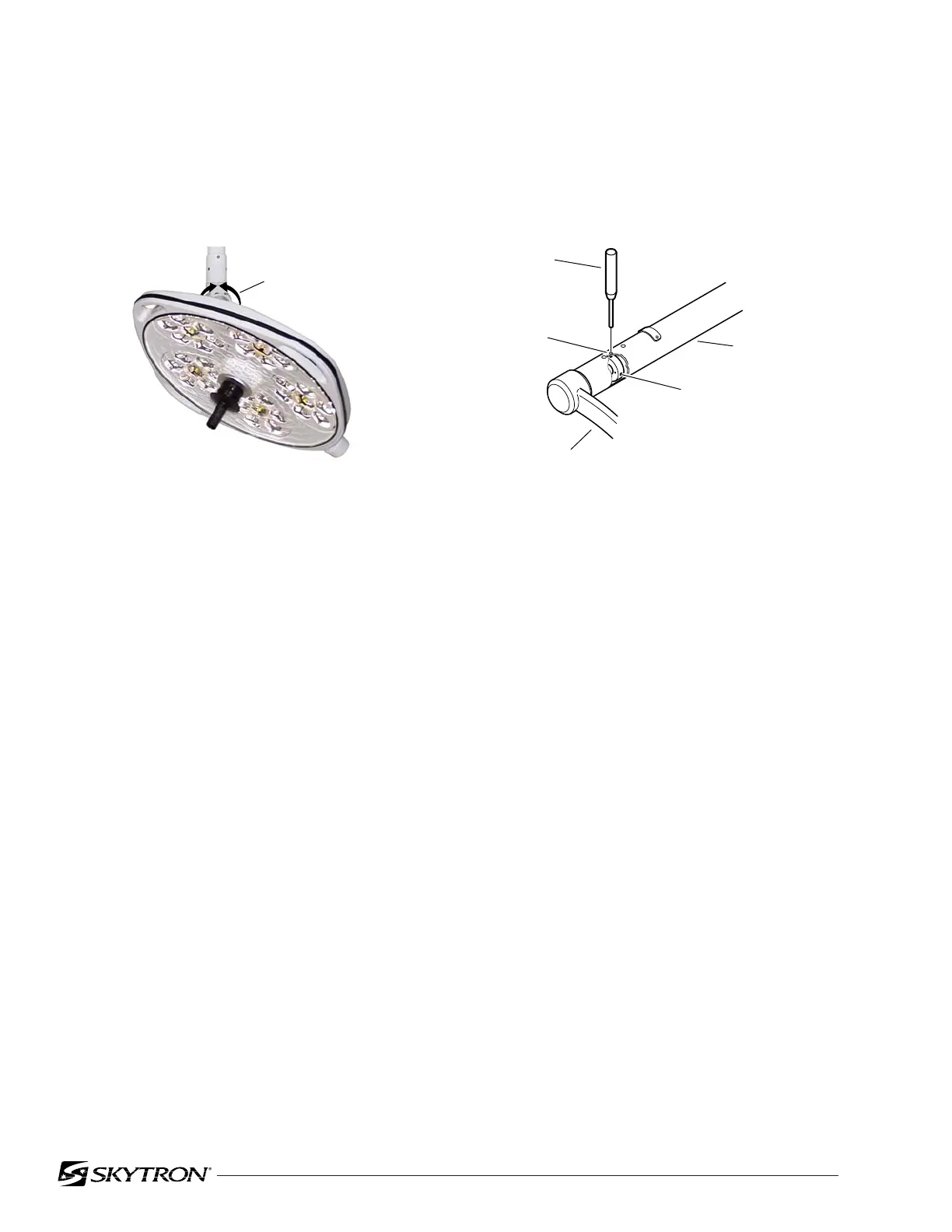

b. The lighthead should move freely yet main-

tain its position without drifting. If an adjustment is

required, refer to figure 2-7 and proceed as follows:

c. Rotate the yoke until an allen set screw is

visible through the adjustment hole and loosen the

set screw. Rotate the yoke 180° and loosen the

second set screw.

2-4. Model 5 Lighthead Roll Adjustment

a. Check the roll axis tension of the model 5

lighthead by moving it through its full 360° range of

travel. See figure 2-6.

Figure 2-7. Model 5 Roll Adjustment

d. Continue to rotate the yoke until a 5mm hole

is visible through the hole. Insert a pin punch into

the hole in the adjustment nut.

e. With the tension nut held captive with the pin

punch, rotate the yoke clockwise (viewed from the

front) to increase the friction and counterclockwise

to decrease the friction.

f. Remove pin punch and check the lighthead for

proper tension. Repeat adjustment procedure if

necessary. After the adjustment is correct, be sure

to tighten the set screws.

B

SUPPORT

ARM

YOKE

SET SCREW (2)

HOLE

PIN

PUNCH

Loading...

Loading...