Page 19

LFS Height Adjustable Arm Tension

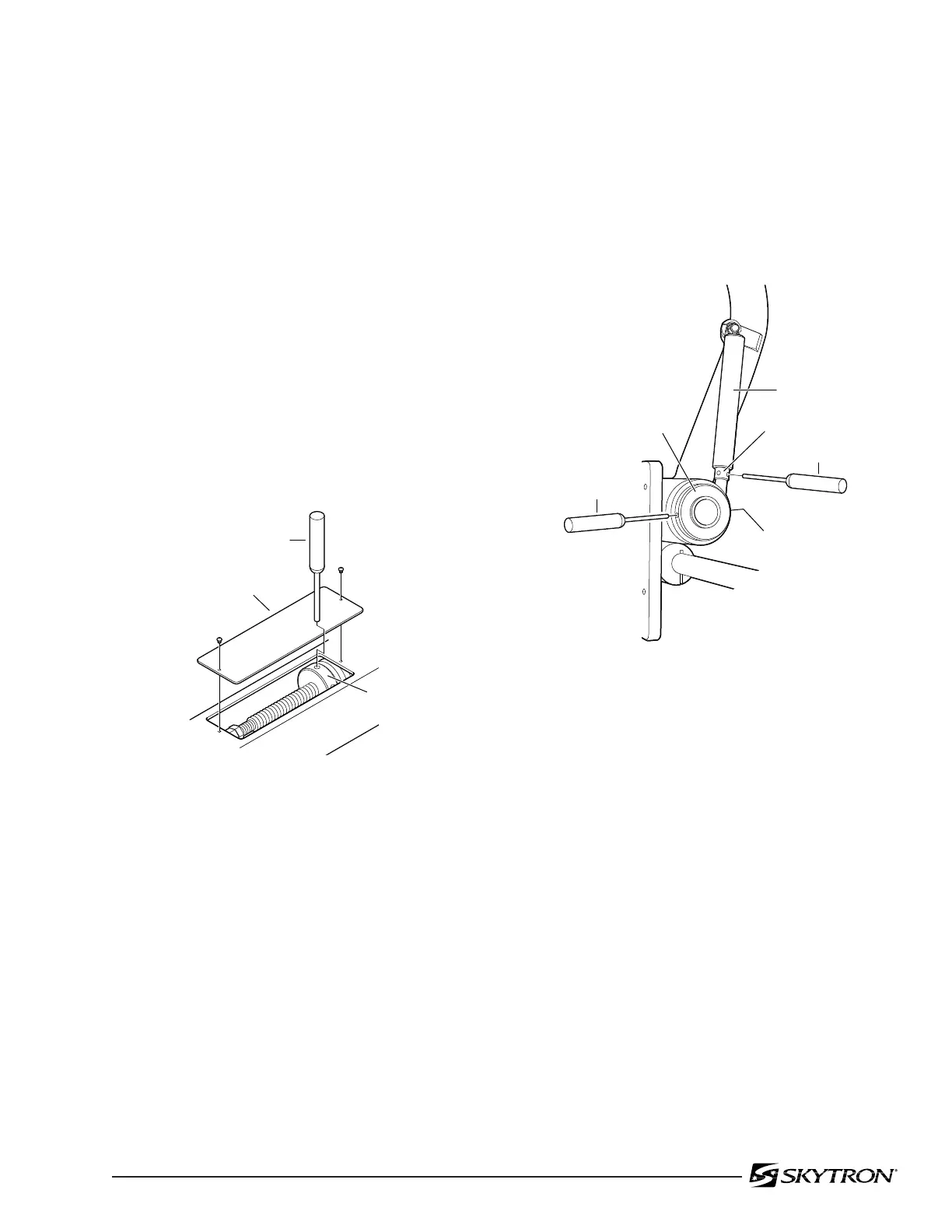

Adjustment

a. Check the vertical tension adjustment of the

Height Adjustable Arm for its capacity to support

the flatscreen monitor throughout its range of mo-

tion. The monitor should move freely yet maintain

its selected position without drifting. If an adjust-

ment is necessary, refer to figure 19 and proceed

as follows:

NOTE

The System can support and balance a

monitor weight up to 20 lbs. Exceeding

the weight will result in poor balance

and performance.

Figure 19

b. Remove the cover plate on the top of the

Height Adjustable Arm for access to the tension

adjustment nut. Insert a 1/8" pin punch into a hole in

the adjustment and turn the nut as required to

achieve proper tension - clockwise to increase

tension, counterclockwise to decrease tension.

Replace access cover when adjustment is com-

plete.

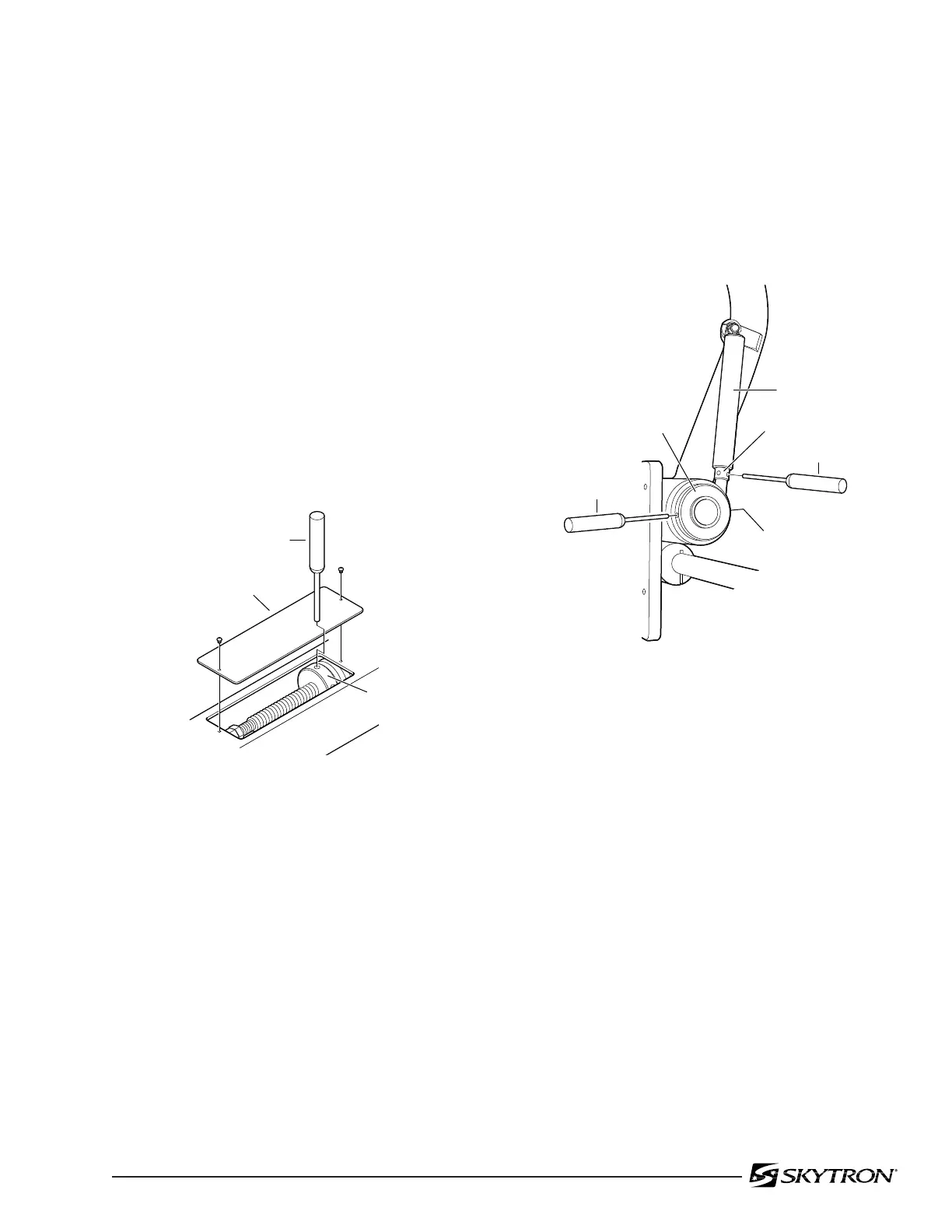

Figure 20

d. Loosen set screw on trunnion nut, insert a

1/8" pin punch into hole opposite set screw location

and adjust trunnion nut as required - clockwise to

increase tension, counter clockwise to decrease

tension. Tighten set screw when adjustment is

complete.

e. For fine adjustment, rotate the monitor down-

ward until the adjustment nut is visible on the

tension spring assembly. Using a pin punch, turn

the adjustment nut until proper tension is achieved.

c. Check the adjustment for the flatscreen

monitor pitch axis. The monitor should move freely

yet maintain its selected position without drifting. If

an adjustment is necessary, refer to figure 20 and

proceed as follows:

COVER PLATE

1/8" PIN PUNCH

ADJUSTMENT

NUT

PIN PUNCH

1/8"PIN

PUNCH

ADJUSTMENT NUT

TRUNION

NUT

SET SCREW

TENSION SPRING

Loading...

Loading...