NOTES

3/4" support rods located for total support of light, all labor and materials for fabrication supplied by General

Contractor. 3/4" nuts and washers for support of SKYTRON mounting plate supplied by contractor (8 ea. required).

The mounting structure must be attached to structural ceiling and BRACED TO ALLOW NO TWISTING OR

LATERAL MOTION and shall be designed not to provide a degree of rotation greater than two-tenths of a degree at

the mounting plate.

3/4" metal conduit and minimum 12AWG wire size (3 wires per lighthead) required between fixture and SKYTRON

supplied wall control. All metal conduit, wiring, and other electrical materials as well as installation labor for such

materials associated with the installation of the SKYTRON surgical light to be provided by Electrical Contractor. All

installations of SKYTRON surgical lights should be under the direct supervision of a SKYTRON representative. All

wiring to be in accordance with local codes and by a certified electrician.

Optional Camera Ready Systems require a 1” diameter conduit from the fixture junction box to the camera control

connector junction box. 65’ camera control cable with faceplate and connector supplied by SKYTRON. Conduit and

2” x 4” junction box supplied by General or Electrical Contractor.

CONTRACTOR HAS FINAL RESPONSIBILITY for the strength and stability of the Mounting Structure.

This is a GENERAL GUIDELINE ONLY.

HEADROOM CLEARANCE INCREASE - 2"

1.

2.

3.

4.

5.

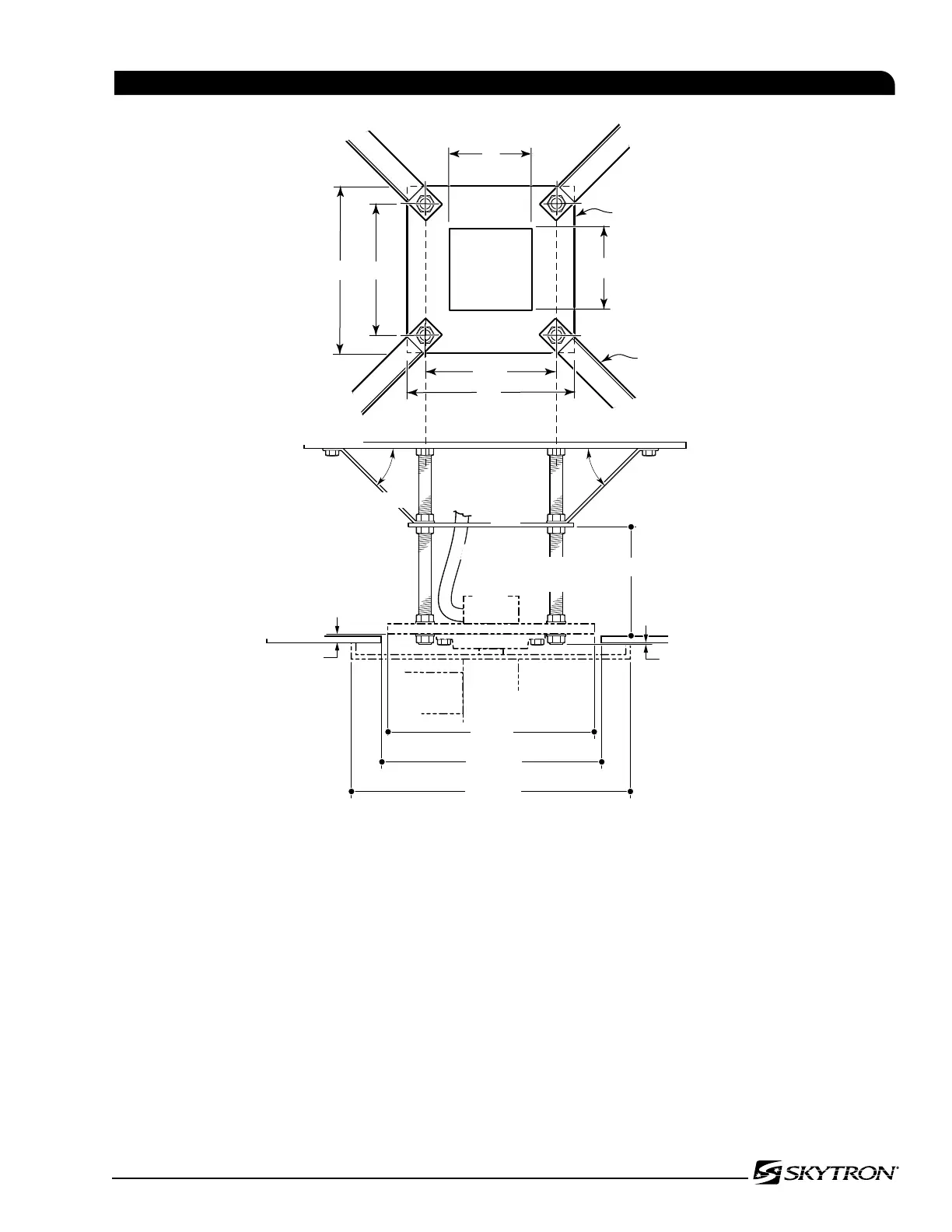

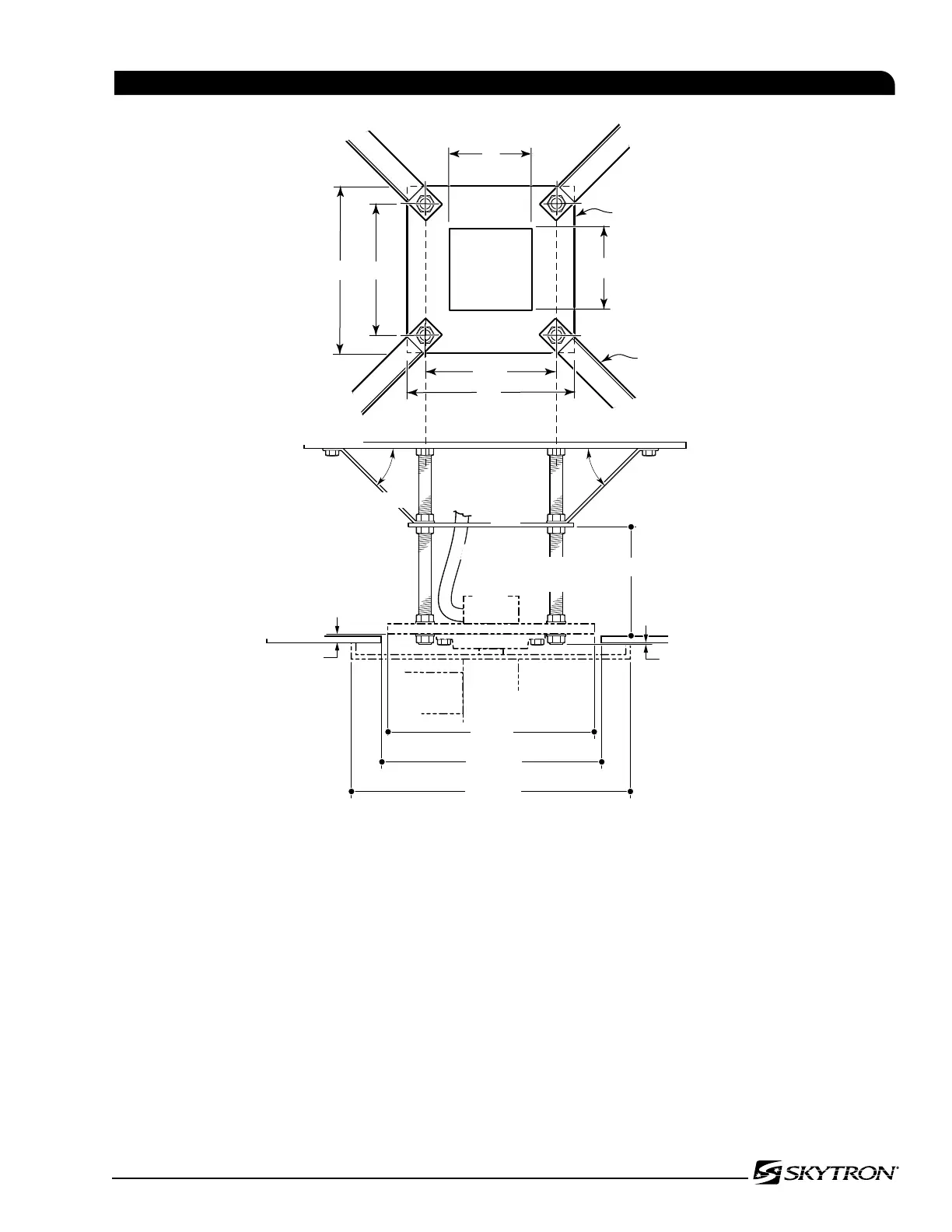

RECESSED MOUNTING STRUCTURE GUIDELINE

45°45°

3/4" Metal

Flex Conduit

(see note 3)

Fixture

Junction

Box

3/4"

All Thread Rod

(see note 1)

1/4"

12" x 12" x 3/8"

Stiffener

Plate

15" dia.

Mounting Plate (SKYTRON Supplied)

20-1/8" dia.

Ceiling Cover (SKYTRON Supplied)

Structural Ceiling

Finished Ceiling

(4) 2" x 2" Angle Sway

Bracing

(see note 2)

STIFFENER PLATE

(provided by others)

9-1/2"

9-1/2"

12"

12"

6"

6"

STIFFENER PLATE DETAIL

TOP VIEW

2" x 2" ANGLE SWAY BRACING

90° APART - 4 EACH

(see note 2)

3/4"

16-1/2" dia.

Access Hole

Hole for

Access to

Fixture

Junction

Box

6" Max/ 4” Min.

Loading...

Loading...