Page 26

WARMING CABINET OWNER’S

• REV2

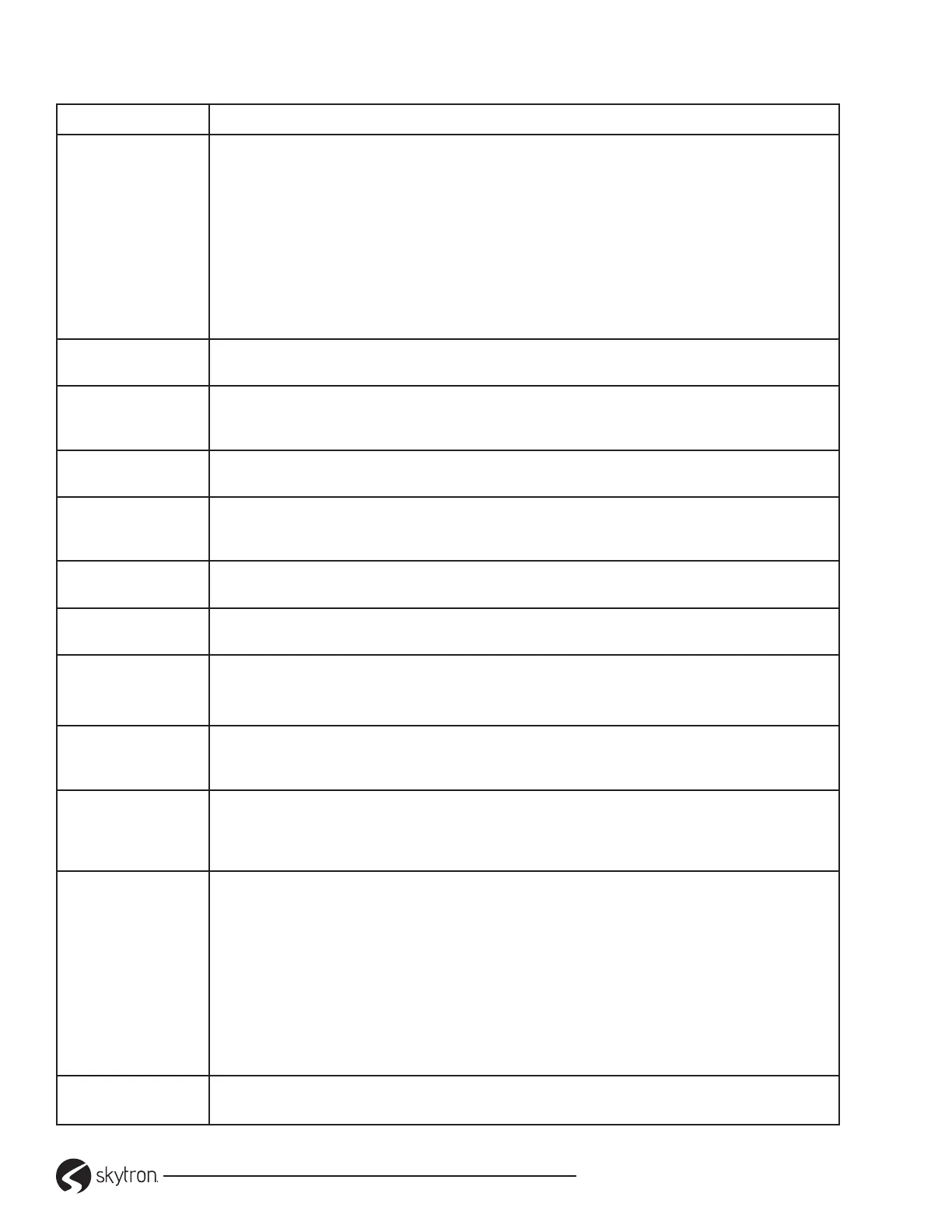

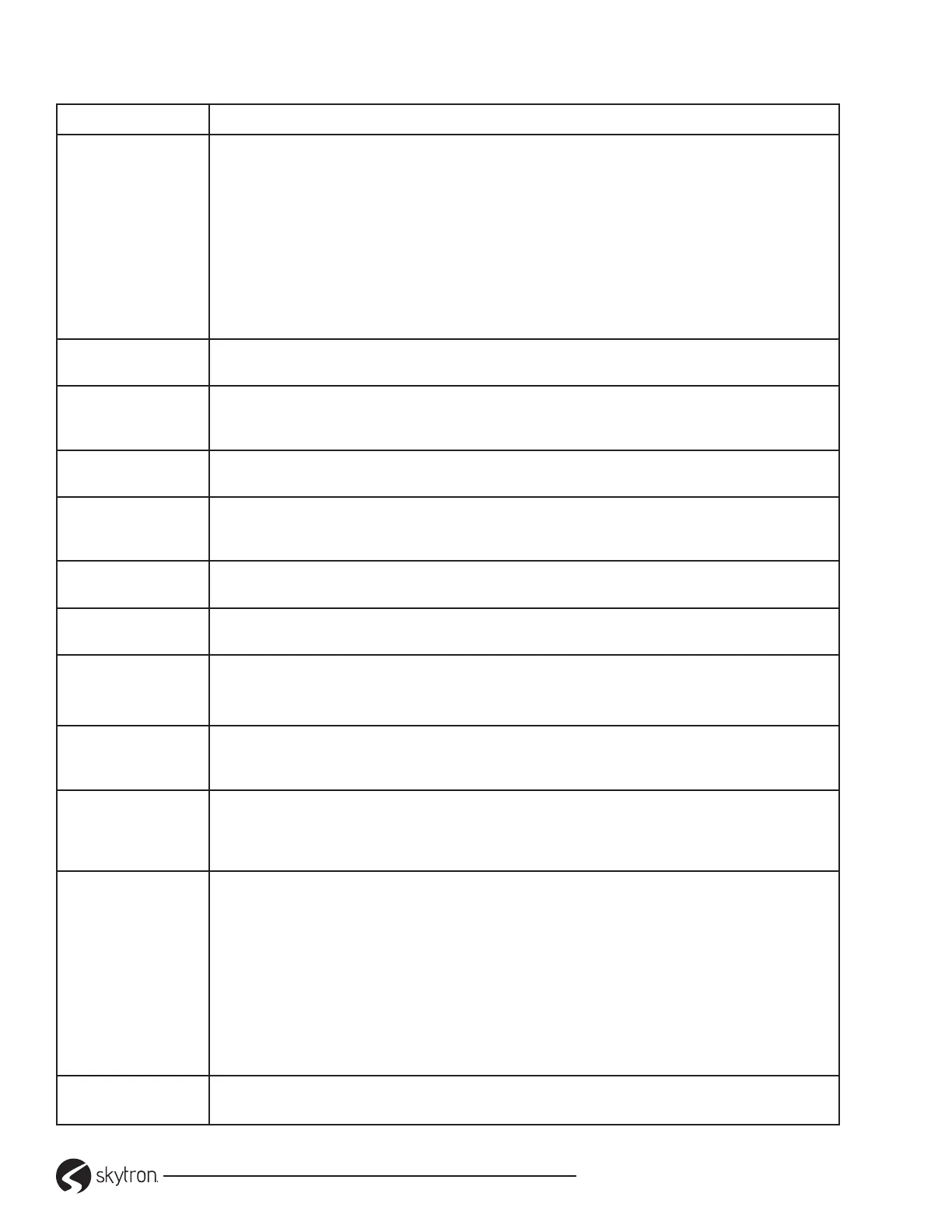

6-2. Touch Screen Controls Troubleshooting Guide

Alarm Description Explanation/Corrective Action

Over Temperature Alarm

is Activated

1. Is the circulating fan operational?

2. Are the contents loaded properly?

3. Has the chamber set temperature been lowered?

4. Lower chamber temperature cannot be in excess of +30° F (+1.1 °C) above an upper chamber.

When cabinet temperature exceeds the setpoint by 10° F (5 °C) or the set temperature is lowered by more

than 10° F (5 °C), the display will ash the Alarm icon and an audible alarm will sound.

Turn off the chamber and wait for the contents to cool adequately. Unload the contents using personal

protective equipment to avoid injury. Reload contents using proper loading guidelines stated in this manual.

Turn on the chamber and monitor performance. If the chamber continues to overheat and the alarm sounds,

turn off the chamber and contact your authorized service personnel.

“Tagname” A to D

Converter Failure

(error code 40) Indicates that the analog to digital converter in the data series controller indicated by

“tagname” has failed. Return to factory for repair or replace.

Auto Tune Failed for

“Tagname”

(error code 26) Indicates that auto tune was unable to execute properly for the data series controller

indicated by “tagname” Verify that PB>0 and TI>0 before starting auto tune. Try manual tuning instead of

auto tuning if the process has a very slow response.

“Tagname” Cold

Junction Failure

(error code 30) Indicates that the cold junction compensation in the data series controller indicated by

“tagname” has failed. Return to factory for repair and replace.

Communications Error

with “Tagname”. Check

Cable.

Check communication wiring between COM2 of the system touch screen and the data series controller

indicated by “tagname” Verify that the data series control has the proper communications address and

communications settings.

“Tagname” EEPROM

Failure

(error code 29) Indicates that the memory in the data series controller indicated by “tagname” has failed.

Return to factory for repair or replace.

Email Error! Check

Cable or Server Down.

Indicates that system was unable to send an alarm message through the mail server. Verify that system is

properly connected to the network and that the email settings and addresses are valid.

FTP! Check Cable or

Server Down.

Indicates that the FTP back-up attempt of the data les failed. Verify that system is properly connected to the

network and that the FTP settings are valid.

If system is not connected to a network, disable the FTP data back-up to prevent seeing this alarm.

NTP Ping Failed. Check

Cable

Indicates that system was unable to synchronize its clock with the selected national time server. Verify that

system is properly connected to the network and the selected time server is accessible. If system is not

connected to a network, disable the NTS clock to prevent seeing this alarm.

“Tagname” Outputs

1 and 2 Incorrectly

Congured.

(error code 4) Indicates that the control data series conguration for the data series controller indicated by

“tagname” is not valid and must be corrected to clear the alarm. Check and correct setup values of output 2,

PB, TI and output 1. If output 2 is required for cooling control, the control should use PID mode (PB > 0, TI >

0) and output 1 should use reverse mode (heat action), otherwise don’t use output 2 for cooling control.

Program Run Error.

“loop 1” and “loop 2” are

Not Synchronized.

Alarm applies to dual systems only and indicates that the running program (in each control) is operating with

a difference of more than 1 minute between the steps programmed for each system.

NOTE: This alarm does not affect program operation. To clear alarm, stop the program. If alarm will not clear,

but the program indicates it is off, select “Stop” from the Program menu and try to clear the alarm again.

The timing accuracy of the system data points controls is + 30 seconds per month. This may cause one

system control to execute the program slightly faster than the other. For programs with long term operation,

weeks of months, one system may get signicantly ahead of the other causing it to begin its next ramp or

soak step ahead of the other affecting product or test results.

Verify that the program end set point conguration for each system is set to the same function. Verify that the

event input functions (if used) are congured for the same function.

“Tagname” Sensor

Break

Check sensor wiring for the system controller indicated by “tagname”. Verify lead connections. If sensor

requires power, verify power to sensor.

Loading...

Loading...