- 26 -

Part to be

tightened

Model

Tightening torque

+/- 10% [Nm]

(3) Housing

(2) Cross recessed round

head screw

2

∗

∗

∗

(3) End cover

∗

∗

(2) Hexagon socket head cap

screw

∗

∗

Band stopper

∗

(1) Round head combination

screws

∗

M3x6

∗

LEF∗40

0.63

10-2. To reassemble, mount the parts in reversed order of removing. Points to be Noted for

Assembly.

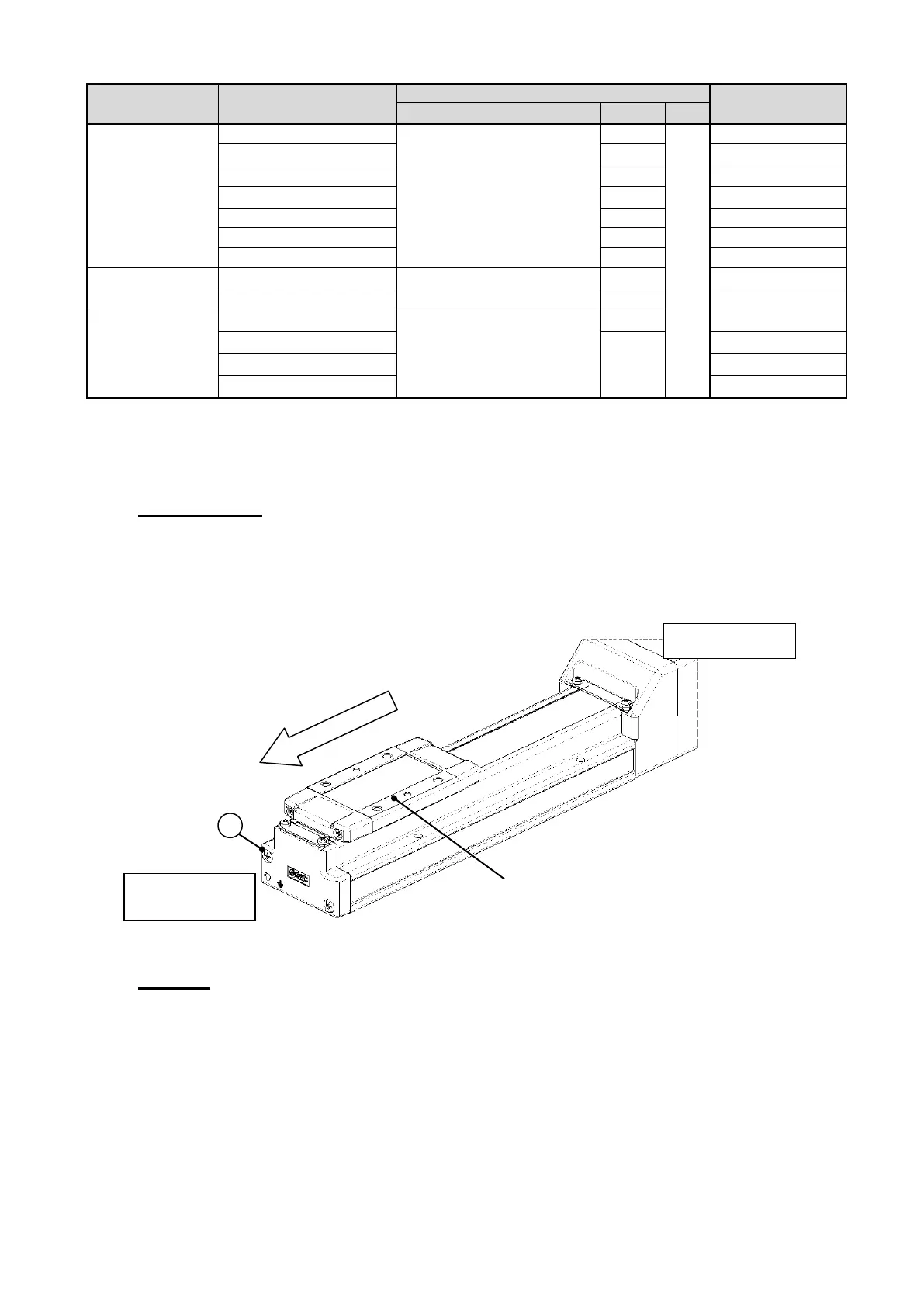

Cautions 1):

Ball screw type

Before fixing the housing, it is necessary to align the slide bearing and the ball screw

axis.

Move the table to the opposite side of the motor as much as possible. And then,

tighten the screw (2).

∗ When they are misaligned, there will be vibration and noise while the actuator is in

operation.

Cautions 2):

Belt type

It is necessary to adjust the belt tension.

Refer to the Chapter 5 LEFB Belt Tension Adjustment.

Cautions 3):

Pull the dust seal band smoothing out the band with a finger from the motor side so

that there will be no deflection in the band, and then hold the band with a band

stopper.

For the replacement of the housing, order the part referring to the spare parts list in

the attachment.

Table.10-1 Fixing screws of the housing (end cover) and band stopper

Opposite side

of the motor

Loading...

Loading...