- 5 -

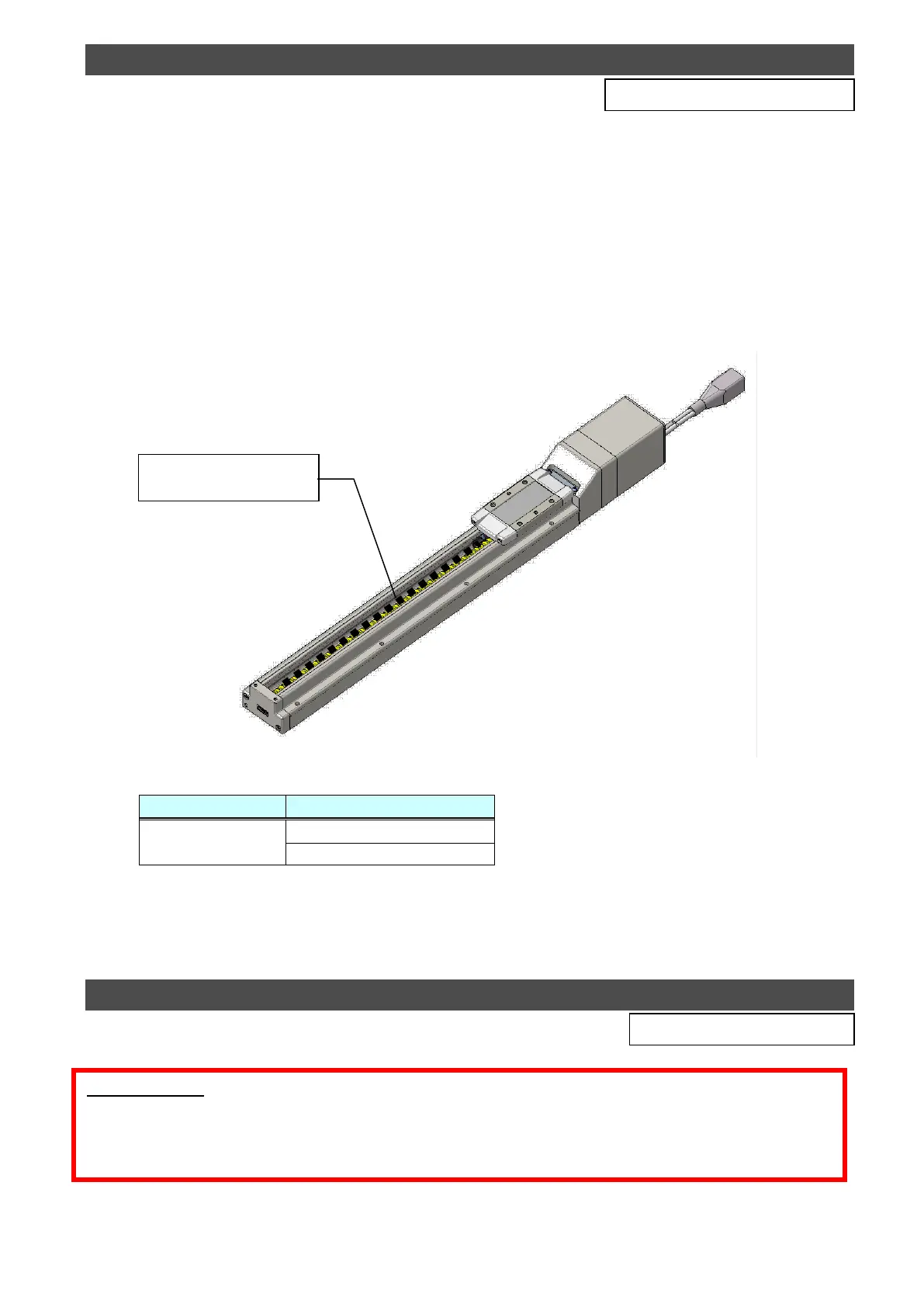

4. Replenishment of grease for the ball screw

4-1. Remove the dust seal band. ( Refer to Chapter 2 Mounting and removal of the dust

seal band and seal band stopper assembly)

4-2. Apply grease to the entire ball screw shaft using a spatula.

Slowly slide the table by hand so that the grease is applied to the inside of the ball

screw nut.

After replenishment, perform several test runs to allow the grease to spread evenly.

* For lubrication, use lithium grease No. 2.

When ordering the grease from SMC, please order a grease pack: GR-S-.

* Not applicable for clean series, secondary battery or special product. Please contact

SMC.

Table.4-1 Grease package (Lithium grease No. 2) A

Refer to the

above figure

4-3. Mount the dust seal band. ( Refer to Chapter 2 Mounting and removal of the dust seal

band and seal band stopper assembly)

5. LEFB Belt Tension Adjustment

Fig. 4-1 Places of grease application

It is recommended to use a belt tension meter.

If you do not have a belt tension meter, align the belt back to the original position that was

marked before removal.

Recommended belt tension meter: (Gates Unitta Asia: U-508)

Loading...

Loading...