Mx37y_Technical_Description_ENG_v2.00.doc

9

─ Single- and three-phase electronic meters with built-in DLC

modem, GSM/GPRS modem or RS485 comm. interface

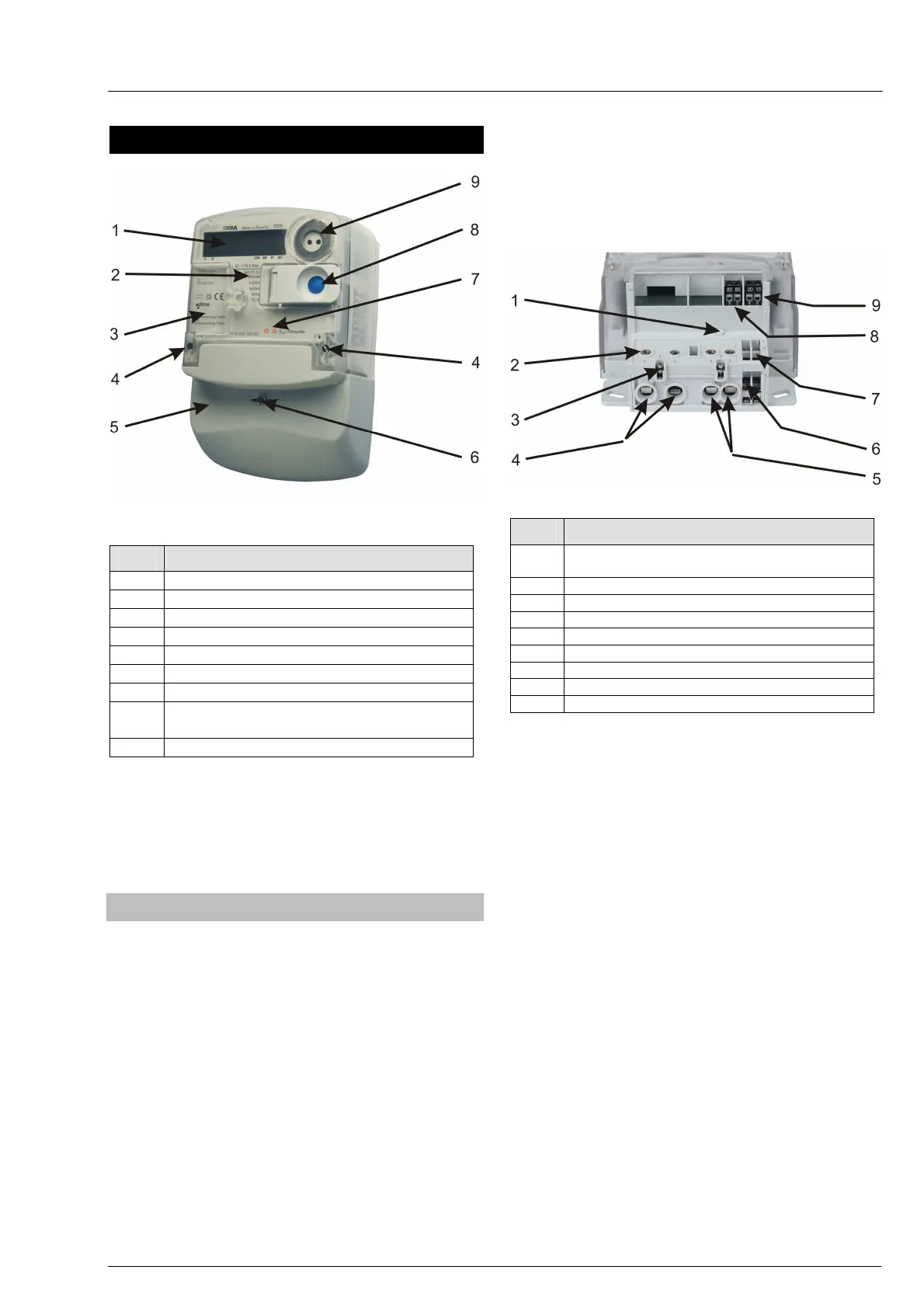

2. Meter appearance (ME37y)

Fig. 3: Meter ME37y constituent parts

ITEM DESCRIPTION

1 Liquid crystal display (LCD)

2 Meter tehnical data

3 Legend for data displayed on LCD

4 A meter cover sealing screw

5 A terminal cover

6 A terminal cover sealing screw

7 Impulse LED

8 Scroll (blue) and Reset (orange) push-

buttons

9 IR optical interface

Two screws for fixing the meter cover (item 4) are

sealed with metrological seals.

The screw for fixing the terminal cover (item 6) and

the Reset push-button lid (item 8) are sealed with

seals of electric utility.

2.1. Meter case (ME37y)

A compact meter case consists of a meter base with

a terminal block and fixing elements for mounting the

meter, a meter cover and a terminal cover. The case

is made of self-distinguishing UV stabilized

polycarbonate which can be recycled. The case

ensures double insulation and IP54 (IEC 60529)

protection level against dust and water penetration.

The top hanger is provided on the back side of the

meter base, under the top edge. On request, an

extended top hanger can be mounted on the meter

base, which ensures the upper fixing hole height of

155 mm above the line connecting the bottom fixing

holes (DIN 43857).

The meter cover is made of transparent polycar-

bon

ate. A nickel-plated iron ring in the right top corner

is utilized for attaching an optical probe to the optical

port. There is a lid which is fixed to the meter cover

with a hinge. The lid covers the Reset push-button

and can be sealed in the closed position.

The terminal block contains current terminals,

auxiliary terminals and potential links for supplying

potential circuits of the meter.

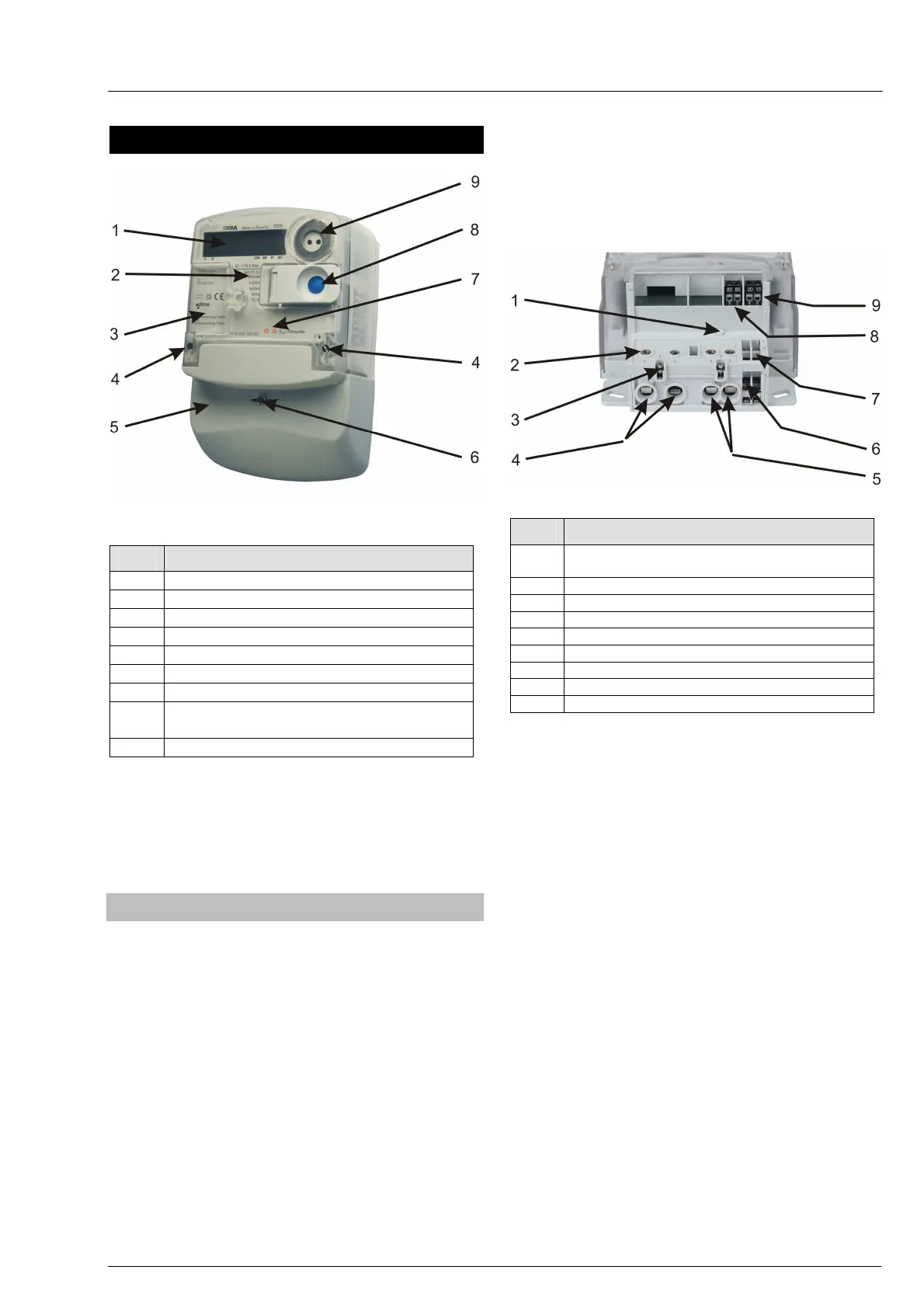

Fig. 4: A terminal block of ME37y meter

ITEM DESCRIPTION

1 A switch for detection of terminal cover

opening

2 A screw for fitting current cables

3 Additional voltage terminals

4 Current terminals

5 Neutral terminals

6 Load control output

7 M-Bus communication interface

8 Second alarm input

9 First alarm input

Current terminals (item 4) are made of galvanized

iron sheet. They are universal terminals for all shapes

and cross sections of connected conductors up to

35 mm

2

. The terminals ensure the same contact

quality with conductors irrespective of whether they

are made of copper or aluminum. Only one screw in a

current terminal reduces time needed for the meter

installation in the field. Due to the indirect pressure on

the conductor it is not damaged.

Up to 8 auxiliary terminals can be fitted in the meter.

They can be utilized for M-Bus, bistable 6 A relay for

load control or alarm inputs. Inputs and outputs are

fitted into the meter regarding the customers request

at meter ordering.

Voltage terminals (item 3) are built into the meter

upon request. They are intended for supplying an

add-on unit from the meter terminal block.

Detectors of opening the terminal cover (item 1) and

the meter cover are built into the meter.

The

terminal cover can be long or short. The meter

connection diagram is stuck on the internal side of

the terminal cover.

Loading...

Loading...