25

EEWB330B

Continuing balancing optimization

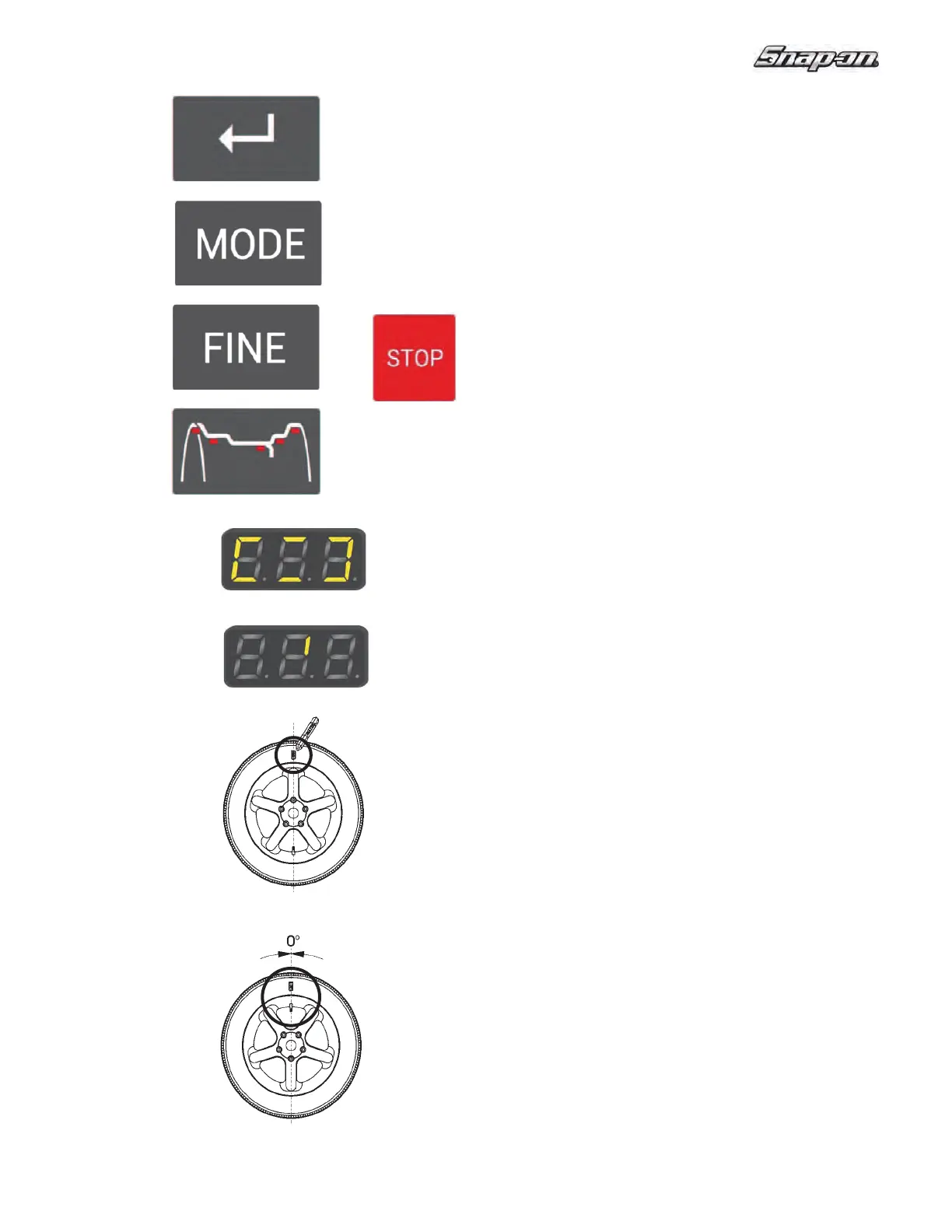

(Fig. 5-34)

• START

the rim compensation run, without the tire.

After the measuring run the O

P

.3

reading appears.

•

Mount the tire and in! ate correctly (see note below).

Note

For mounting and demounting (tire changer) and tire

turning or readjustment on the rim, always apply a

suf" cient amount of tire lubricant on the tire beads and

the rim edges and shoulders. Each time the position

of the tire is changed on the rim, in! ate the tire to

overpressure (approx. 3.5 bar) then de! ate to correct

tire pressure.

Make sure the centering line is correctly positioned on

the tire bead.

• Clamp the wheel.

• Position the valve exactly perpendicular to and

above the main shaft.

• Press the ENTER k

ey (1) to acquire the valve

position.

OP.4 appears (Fig. 5-34).

• Spin the wheel (START).

The measuring run is carried out. After the measuring

run two readings are possible:

OP.5 - H1

Further optimization is not recommended, but possible.

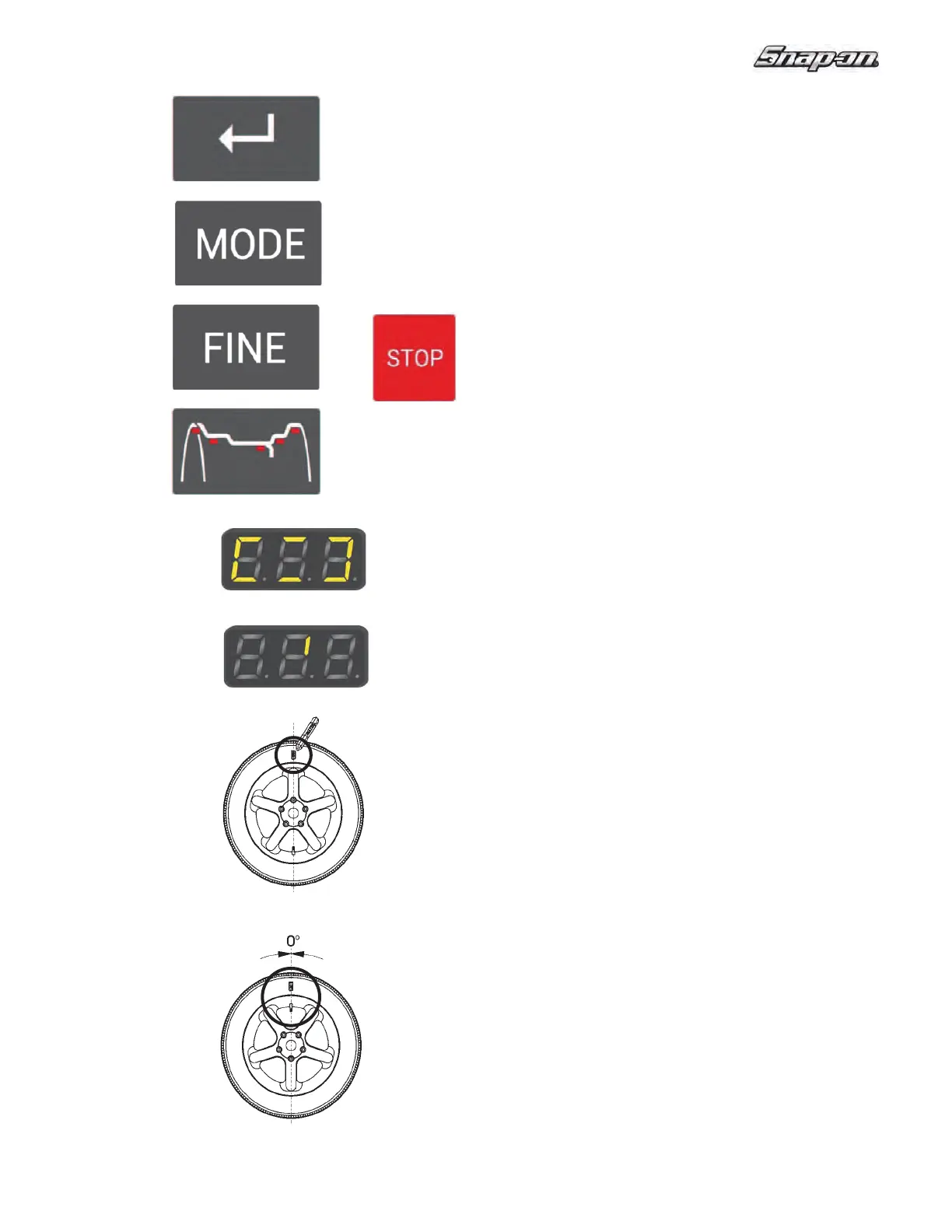

OP.5 – I (1 Reference mark Fig. 5-35)

Continue with the OP program.

Reading OP.5 - H1

If

OP.5 - H1 appears, further optimization is not

recommended, since the measurement values which

activated the optimization recommendation are below

the limit value. However, it is possible to continue

optimization for the most silent possible wheel running,

reducing imbalances below the limit value (critical

vehicle).

To continue optimization

• To continue with the OP program proceed as

speci" ed for OP.5 – I (given below).

To abort optimization

• Press the STOP key to return to the balancing

program and balance the wheel according to the

readings (F 5.9).

5-35

5-36

5-34

5-37

5-32

1

2

3

4

5

Loading...

Loading...