15

EEWB330B

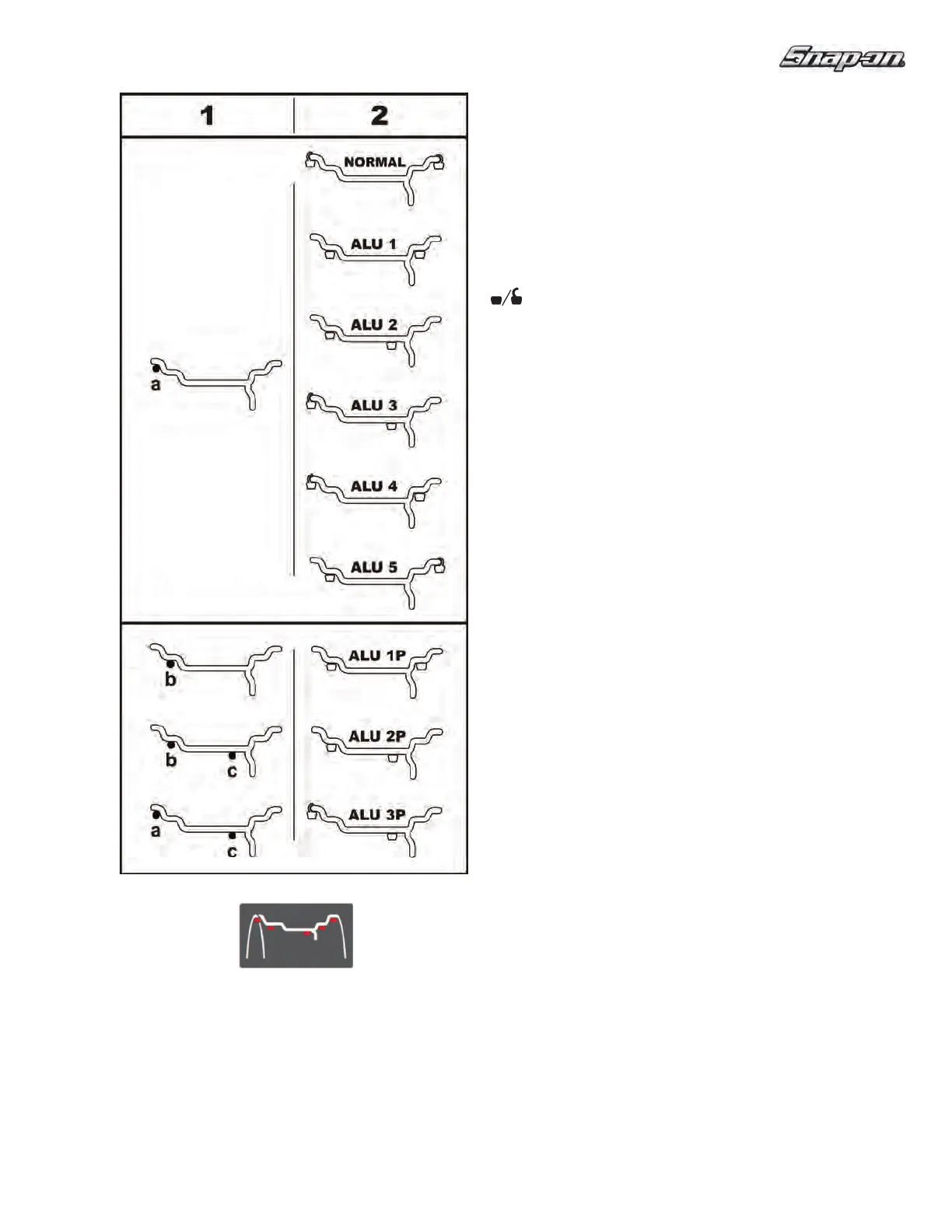

4.3.2 SAPE ARM POSITIONS FOR ALU

WEIGHTS PLACEMENT

Fig.

18 shows the corrected reading positions of the

SAPE arm (1), depending on the required weight

positions (2); adhesive weights and clip-on weights.

Weight Placement illuminated indicators indicate the

weights placement positions on the rim.

— = SAPE arm application point (1).

= resulting in weight position (2).

Normal Tou

ch the SAPE arm to the rim flange (a).

Manually input the rim width dimension. This

mode require the clip-on weights placement.

Alu 1 Touch the SAPE arm to the rim flange (a).

Manually input the rim width dimension. Press

once the Alu key (9). This mode uses the

standardized adhesive weights placement.

Alu 2 Touch the SAPE arm to the rim flange (a).

Manually input the rim width dimension. Press

twice the Alu key (9). This mode uses the

standardized adhesive weights placement.

Alu 3 Touch the SAPE arm to the rim flange (a).

Manually input the rim width dimension. Press

three times the Alu key (9). This mode uses the

standardized weights placement

.

Alu 4

Touch the SAPE arm to the rim flange (a).

Manually input the rim width dimension. Press

six times on the Alu key (9). This mode uses the

standardized weights placement.

Alu 5 Touch the SAPE arm to the rim flange (a).

Manually input the rim

width dimension. Press

seven times on the Alu key (9). This mode uses

the standardized weights placement.

Alu 1P Touch the SAPE arm to the rim ! ange (b). Press

once the Easy Alu Toggle key (9).

Manually input the rim width dimension.

- The internal correction plane for adhesive

weights is precisely indicated by the machine.

Note: Make sure all entries are completed prior to

balancing spin.

Alu 2P Perform the SAPE arm detection in (b-c) points.

- The adhesive weights are placed where the

readings are taken, according to the reading

positions.

Alu 3P Perform the SAPE arm detection in (a-c) points.

- The adhesive weight is placed where the

reading is taken, according to the reading

position.

Note: The Easy Alu Toggle key (6), can retrieve an

alternative ALU P mode.

9

Figure 18

Loading...

Loading...