40

UL, cUL Installation Instructions

1. Input power and output motor field wiring

shall be copper conductors, rated 75ºC.

2. Use UL listed closed-loop connectors sized

for the selected wire gauge. Install connectors

using the correct crimp tool recommended by

the connector manufacturer. Applies only to

units bus bars.

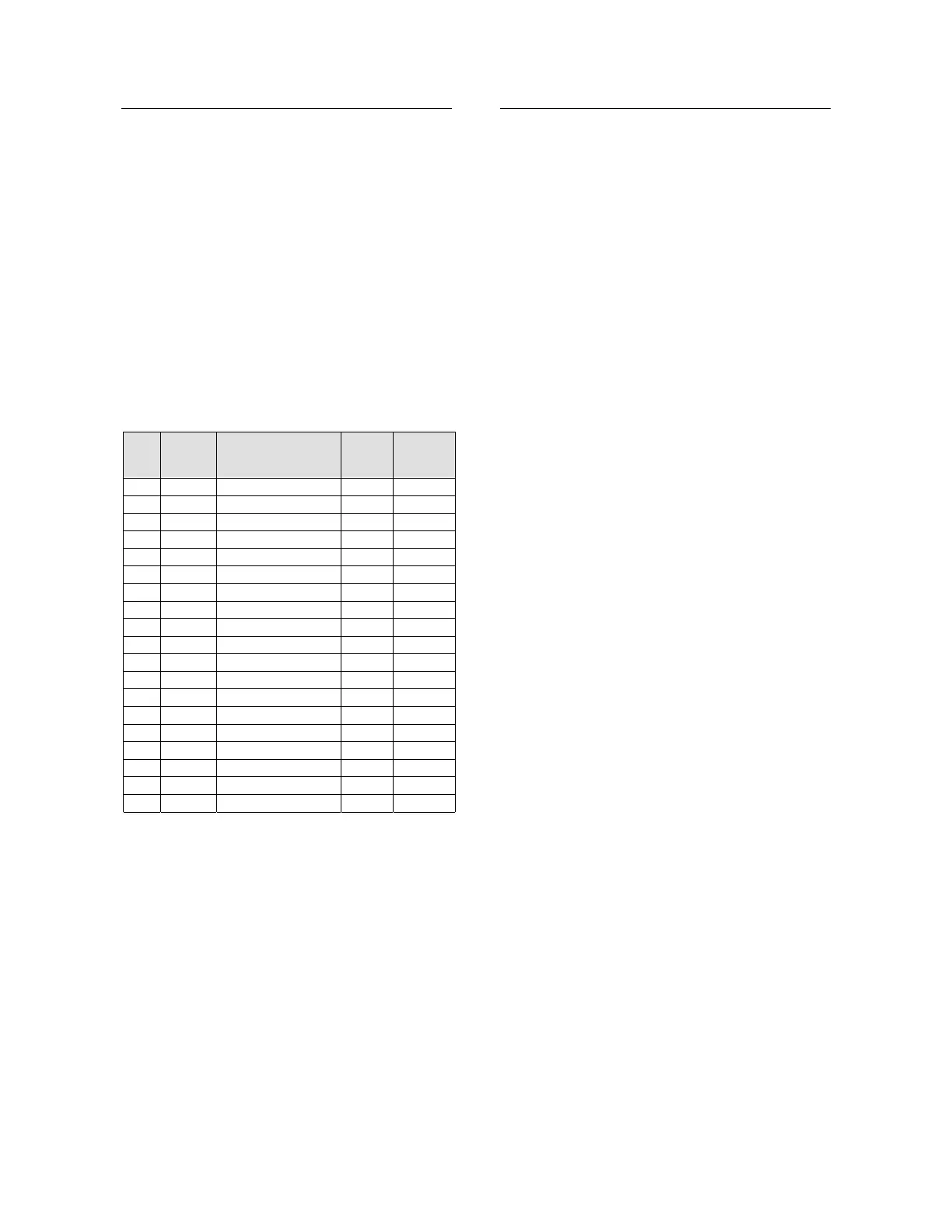

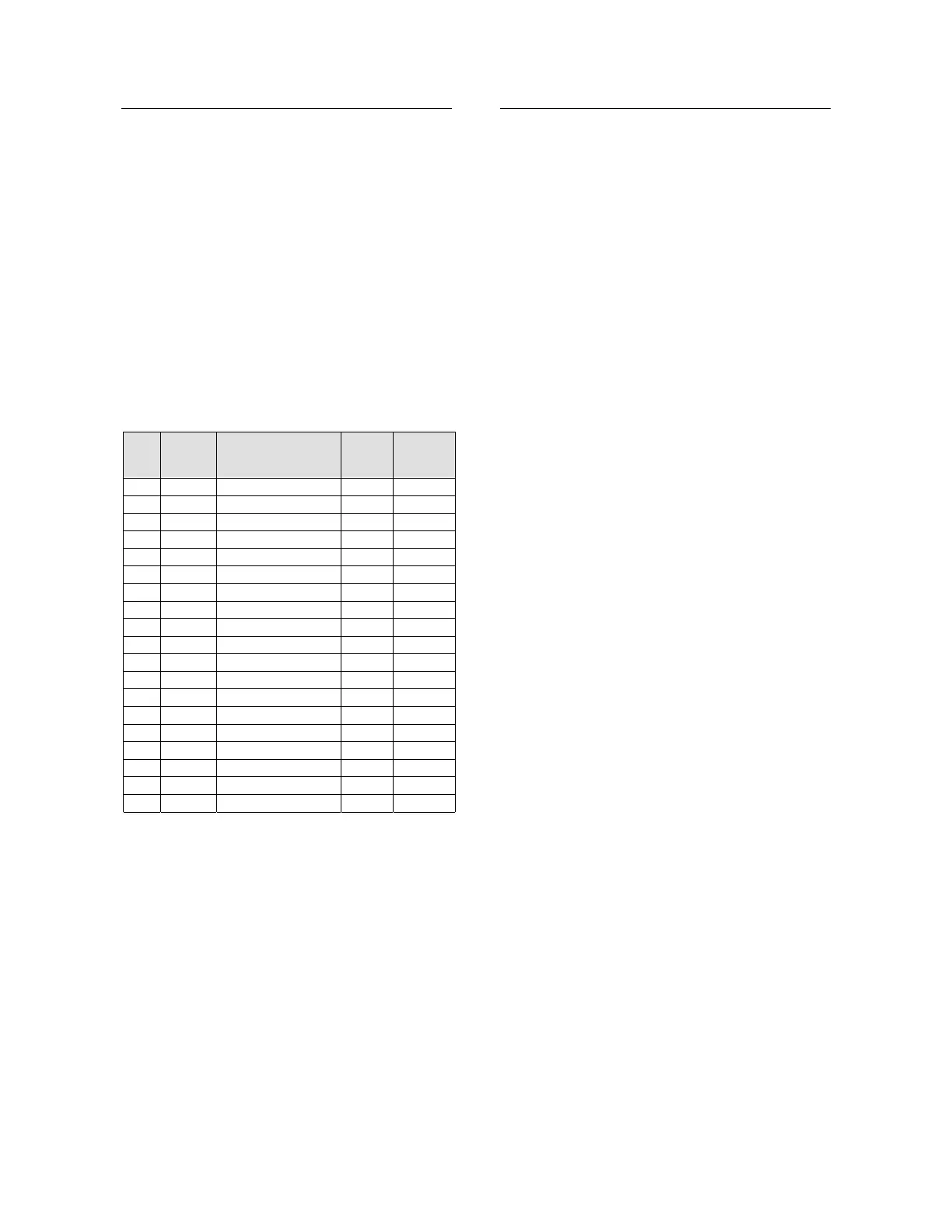

3. Table showing corresponding wire size,

terminal screw, closed-loop connector size.

Torque ratings for attachment of connector to

bus bar (see table).

4. Branch circuit protection, shall be provided

per the NEC.

For units with UL cUL, see ordering information.

Cables, Terminal screws and Torque

recommendations

No.

Max.

Mot.

FLA

Min. dimensions for

copper cables

(mm

2

)

Term

Screw

Mech.

Torq.

Kg.cm

1 8 3 x 1.5 + 1.5

2 17 3 x 2.5 + 2.5

3 31 3 x 6 + 6

4 44 3 x 6 + 6

5 58 3 x 10 + 10

6 72 3 x 16 + 16

7 105 3 x 50 + 50 M8 180

8 145 3 x 70 + 35 M8 180

9 170 3 x 95 + 50 M8 180

10 210 3 x 150 + 70 M10 220

11 310 2 x (3 x 120+ 70) M10 220

12 390 2 x (3 x 185+ 95) M10 220

13 460 2 x (3 x 240+120) M10 220

14 580 3 x (3 x 185+ 95) M10 220

15 820 3 x (3 x 240+120) M10 220

16 1100

17 1400

18 1800

19 2500 TBD TBD TBD

LR Recommendation

LR recommendations for marine, offshore or industrial

use.

System design needs to take into account the power

supply source and the motor drive together with the

electronic soft starter. Particular features to be

considered are torque production, harmonic production

and their consequential effects and EMC. These points

are relevant for marine, off-shore or industrial use.

Loading...

Loading...