19

Original document - Mi-205 EN Edition: 2021-04

* DN80 only for MTV

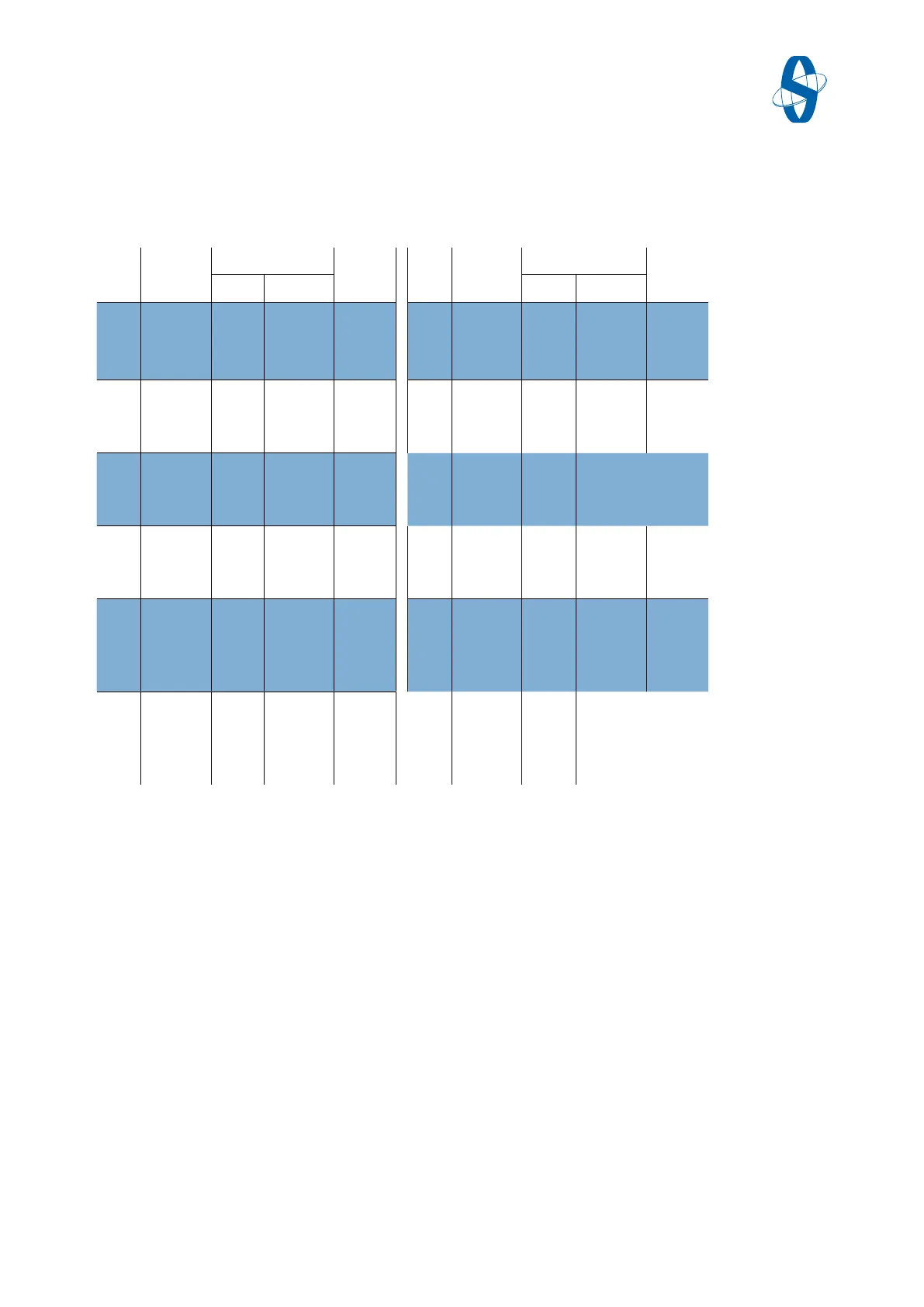

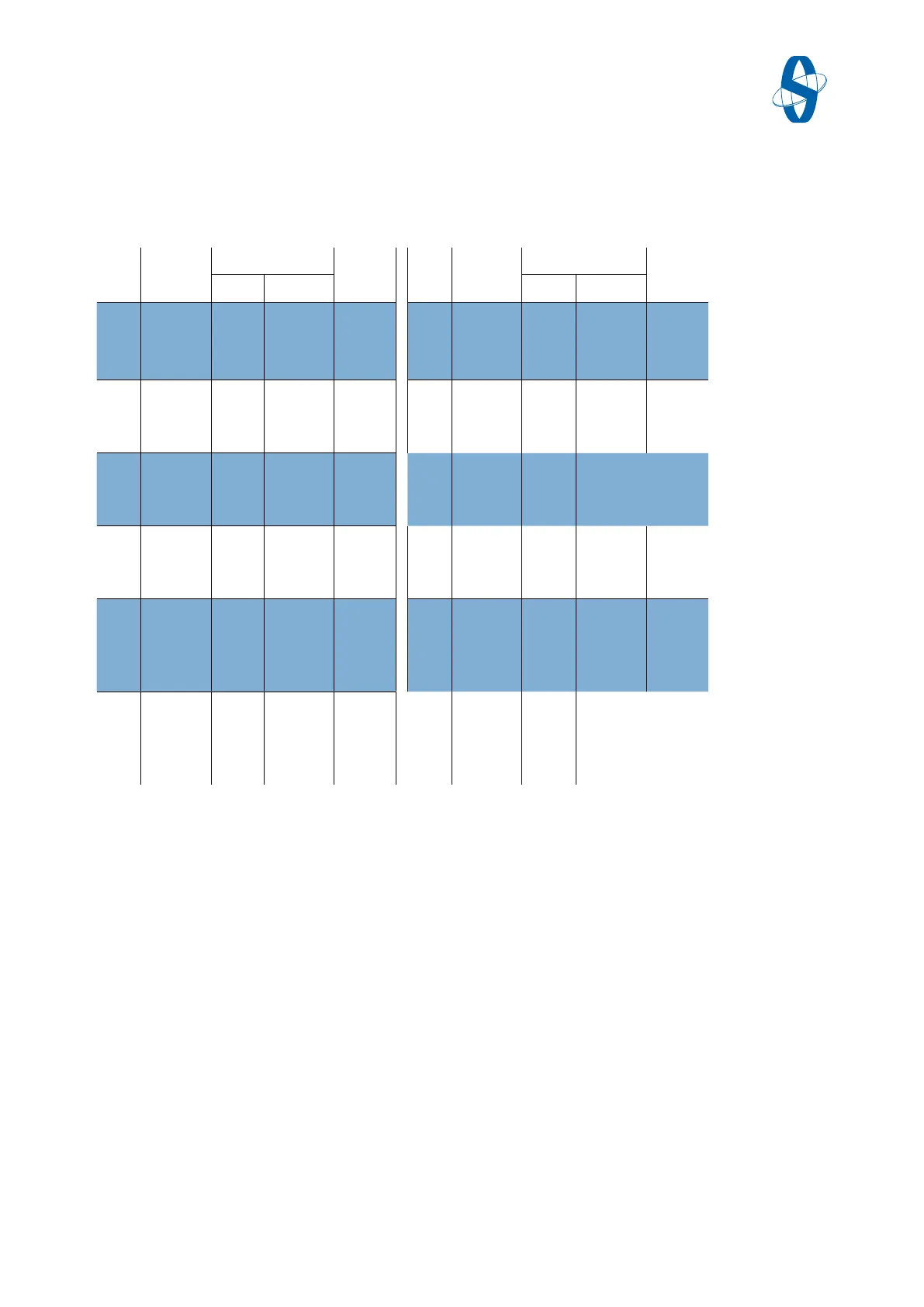

Tab.4-3 Fastening torque for flanges valve body

4.2 Fastening torque for bolts

4.2.1 Fastening torque for flanges valve body

DN PN/Class Screw Torque

(Nm)

1

DN PN/Class Screw Torque

(Nm)

1

Dim. Quantity Dim. Quantity

80* 10, 16, 25

/150

M16

5/8“

8

4

65

120

300 10

16

25

/150

M20

M24

M27

7/8“

12

12

16

12

160

180

205

230

100 10,16

25

/150

M16

M20

5/8“

8

8

8

80

95

70

350 10

16

25

/150

M20

M24

M30

1“

16

16

16

12

215

235

340

280

125 10,16

25

/150

M16

M24

3/4“

8

8

8

90

110

110

400 10

16

25

/150

M24

M27

M33

1“

16

16

16

16

240

300

445

300

150 10,16

25

/150

M20

M24

3/4“

8

8

8

120

140

130

450 10

16

25

/150

M24

M27

M33

1 1/8”

20

20

20

16

210

300

395

405

200 10

16

25

/150

M20

M20

M24

3/4“

8

12

12

8

175

120

140

180

500 10

16

25

/150

M24

M30

M33

1 1/8“

20

20

20

20

245

410

480

355

250 10

16

25

/150

M20

M24

M27

7/8“

12

12

12

12

140

150

200

170

1

The information in the table refers to lubricated bolts. The correction factor for new, unlubricated bolts is 1.5.

Tighten the bolts alternately until the correct tightening torque is reached.

Tightening torque applies to flat gaskets corresponding to non-reinforced and reinforced graphite according to

EN 12516-2: 2014 with m-factor according to ASME 2.0 to 2.5. Maximum thickness for gasket: 2.0 mm. Tightening

torque must not be exceeded, because then the functionality of the valve can be compromised. Tightening

torques in Nm are designed for gaskets according to EN 1514-1, ASME B16.21 and counter flanges according to

EN 1092-1, EN 1759-1, ASME B16.47.

Loading...

Loading...