Appendix C: Cleaning & Service

C-2

WFM 1125 Option 0A/0B/0C/0D User Manual

Inspect the outside of the waveform monitor for damage, wear, and missing

parts, using Table C–1 as a guide. A waveform monitor that appears to have been

dropped or otherwise abused should be checked thoroughly to verify correct

operation and performance. Immediately repair any defects that could cause

personal injury or lead to further damage to the instrument.

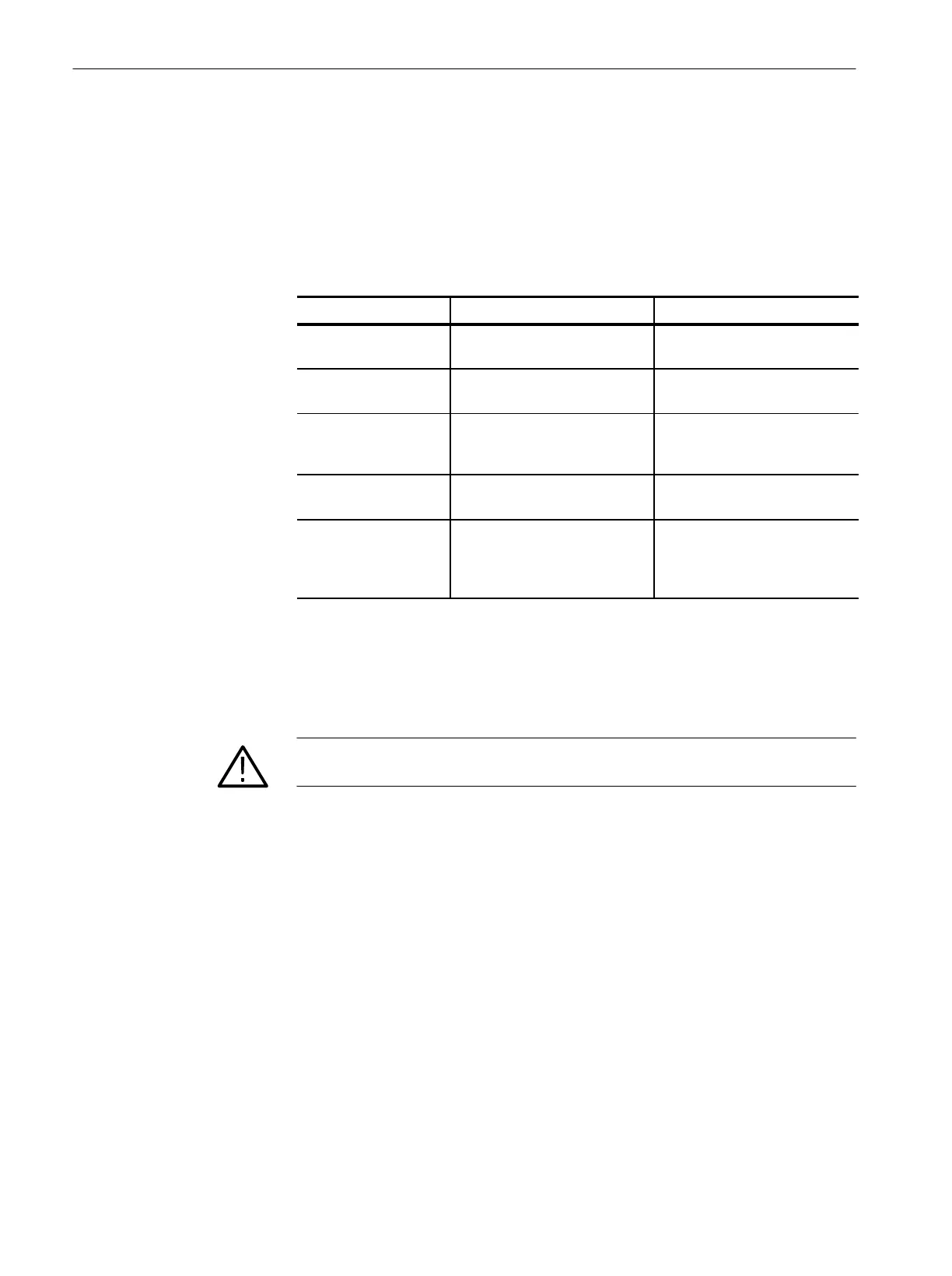

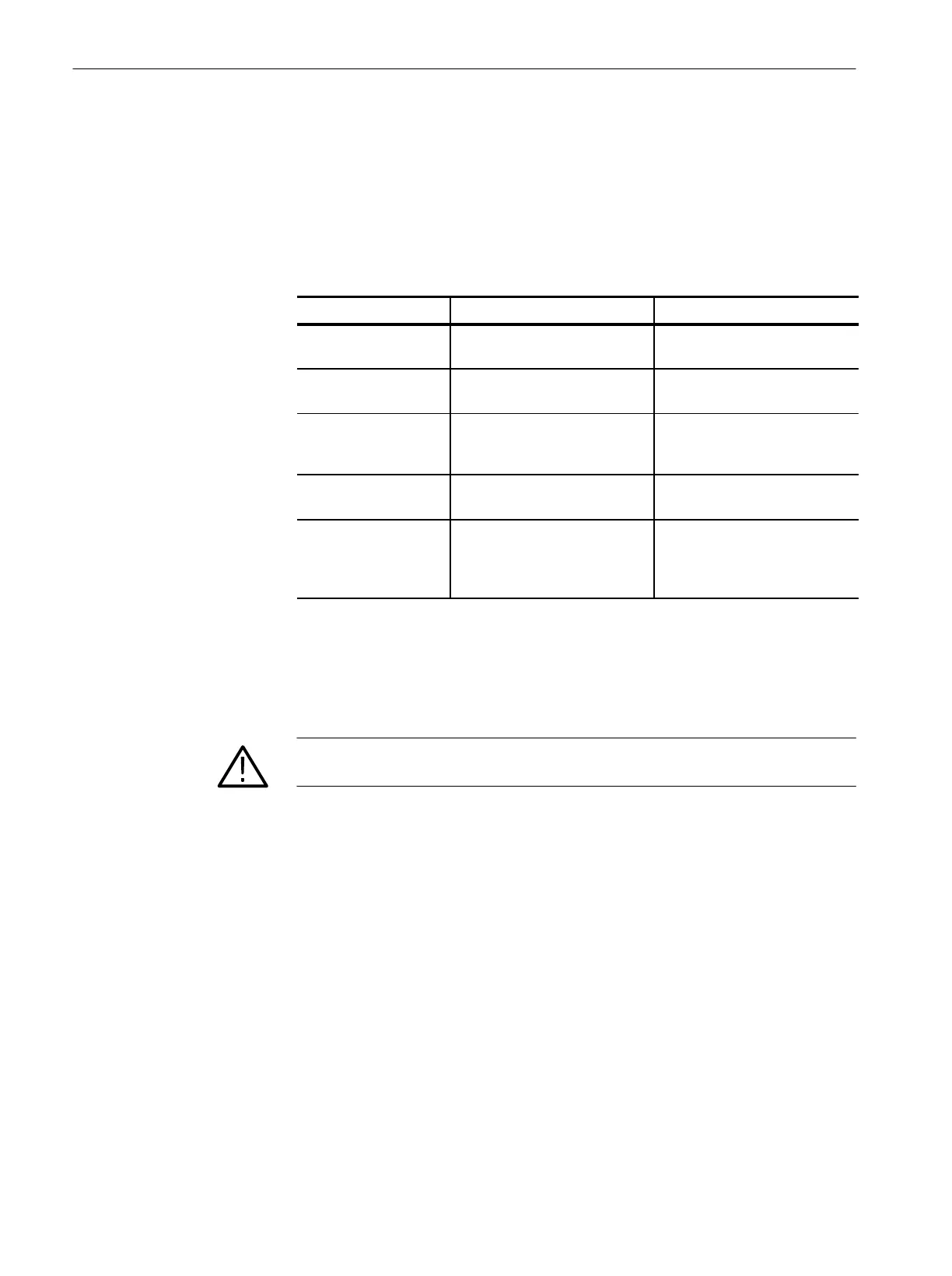

Table C-1: External inspection check list

Item Inspect for Repair action

Cabinet, front panel,

and cover

Cracks, scratches, deformations,

damaged hardware or gaskets.

Repair or replace defective

module.

FrontĆpanel knobs Missing, damaged, or loose

knobs.

Repair or replace missing or

defective knobs.

Connectors Broken shells, cracked insulation,

and deformed contacts. Dirt in

connectors.

Repair or replace defective

modules. Clear or wash out dirt.

Carrying handle, bail,

and cabinet feet

Correct operation. Repair or replace defective

module.

Accessories Missing items or parts of items,

bent pins, broken or frayed

cables, and damaged connecĆ

tors.

Repair or replace damaged or

missing items, frayed cables, and

defective modules.

To clean the instrument exterior, do the following steps:

1. Remove loose dust on the outside of the waveform monitor with a lint free

cloth.

CAUTION. To prevent getting moisture inside the waveform monitor during

external cleaning, use only enough liquid to dampen the cloth or applicator.

2. Remove remaining dirt with a lint free cloth dampened in a general purpose

detergent-and-water solution. Do not use abrasive cleaners.

3. Clean the light filter protecting the monitor screen with a lint-free cloth

dampened with either isopropyl alcohol or, preferably, a gentle, general

purpose detergent-and-water solution.

Inspection

Cleaning Procedures

Loading...

Loading...