Maintenance Waukesha Cherry-Burrell Brand W60/W80 Valves

Page 40 95-03022 08/2018

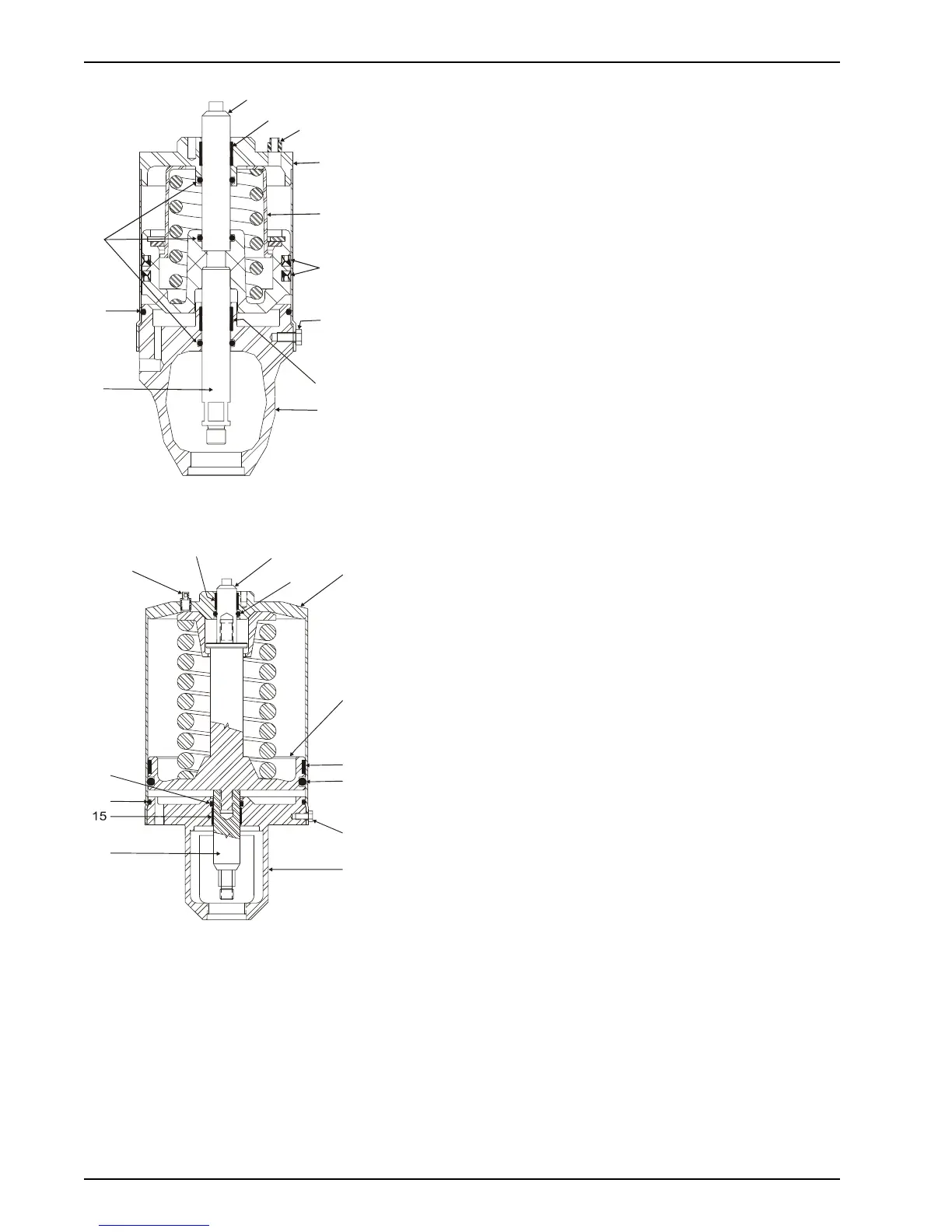

U-cup Replacement: 4" and 5" Actuator

1. Inspect the piston U-cup seal (Figure 36, item 8).

2. Remove the worn U-cup seal. Do not score or nick grooves in

the piston (item 10).

3. Coat the new U-cup seal with Dow Corning

®

#7 Silicone

Lubricant or equivalent.

4. Slightly stretch the lubricated seal to fit over the piston. Install

the lower seal first with the "U" pointing down. Install the

upper seal with the "U" pointing up. U-cup seals flare slightly

at the outer edges when they are properly installed.

5. Place the piston and spring assembly in the cylinder.

6. Place the cylinder over the yoke, and install cap screws (item

9) to secure it.

NOTE: If the stems were disassembled during this maintenance

procedure, clean, prime, and apply Loctite

®

2440 Thread Locker,

according to manufacturer’s specifications, to the upper (items 1,

1a) and lower (item 3) stems. Torque the stems to 200 in/lbs.

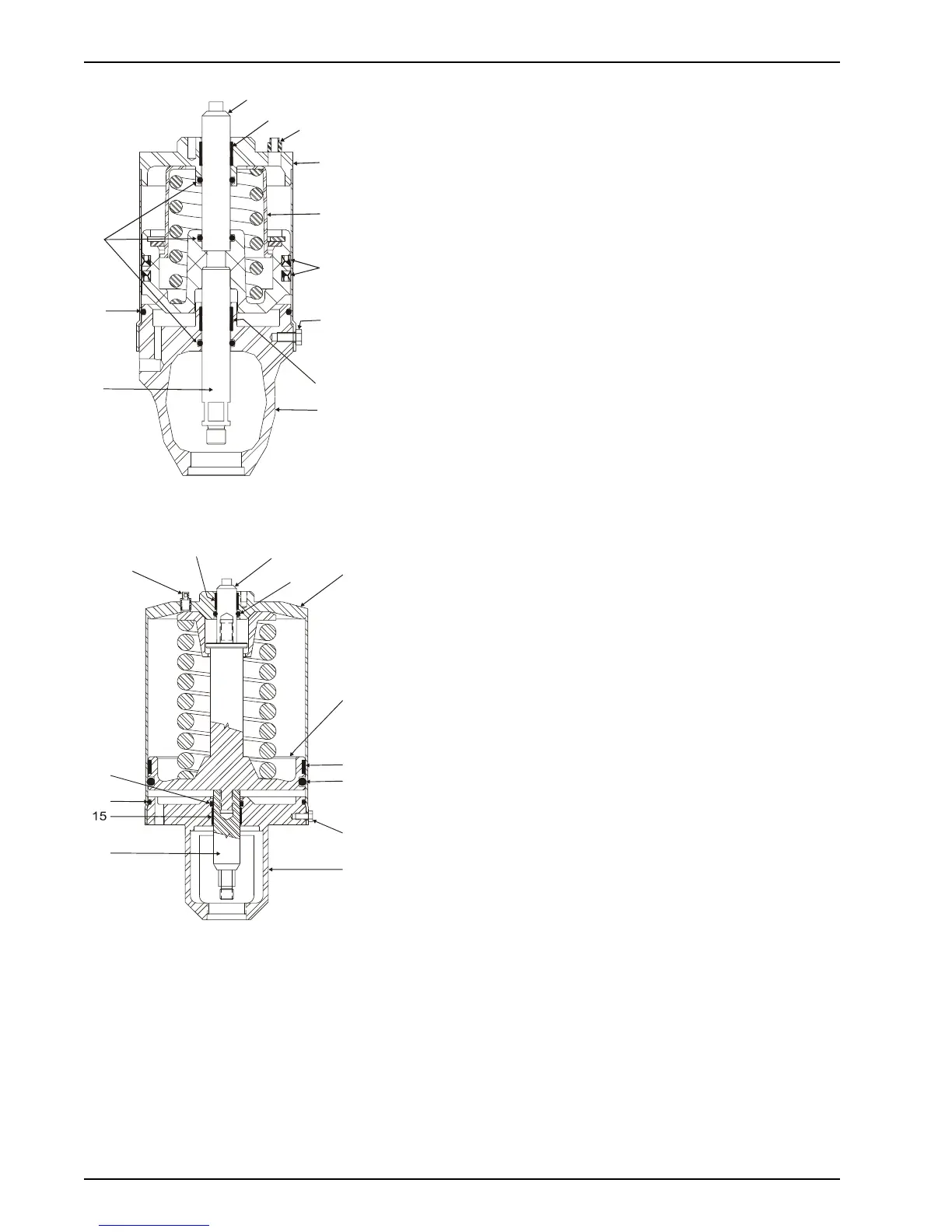

O-ring and Bearing Replacement: 6” Actuator

1. Inspect the piston o-ring seal (Figure 37, item 8).

2. Remove the worn o-ring seal. Do not score or nick grooves in

the piston (item 10).

3. Coat the new o-ring seal with Dow Corning

®

#7 Silicone

Lubricant or equivalent.

4. Slightly stretch the lubricated seal to fit over the piston.

5. Inspect and replace the PTFE guide bearing (item 14) on the

piston as needed.

6. Place the piston and spring assembly in the cylinder.

7. Place the cylinder over the yoke, and install cap screws (item

9) to secure it.

NOTE: If the stems were disassembled during this maintenance

procedure, clean, prime, and apply Loctite

®

2440 Thread Locker,

according to manufacturer’s specifications, to the upper (items 1,

1a) and lower (item 3) stems. Torque the stems to 400 in/lbs.

Figure 36: 4" and 5" Actuator

3

7

6

Figure 37: 6" Actuator

13

1,1a

3

7

Loading...

Loading...