MC521 PRO Control Box

24 Document # 204066 REV D2 • www.stanleyaccesstechnologies.com • 1.800.7.ACCESS

Copyright 2015, Stanley Security Solutions. All rights reserved. Reproduction in whole

or in part without the express written permission of Stanley is prohibited.

10.21.2015

Attachment 4

ANSI/BHMA and UL Compliance Requirements for Sliding Doors

(Sheet 2 of 2)

To ensure that a sliding door operates in accordance with UL 325 entrapment protecon criteria the following must

be established:

• Manual opening force (sliding doors without breakout) or breakout force with power on or o must be less

then 50 lbf (222.4 N).

• Closing force must be less than 30 lbf (133.4 N).

• A closing sliding door must not develop kinec energy in excess of 7 -lbf (9.49 J). This is achieved by proper

seng of the closing speed. See secon entled “Closing Speed”.

• Maximum recommended door weight:

• Dura-Glide 5000 Series = 150 lbs (70 kg) per panel.

• Dura-Glide/Dura-Guard/Dura-Storm and similar 2000/3000 Series = 220 lbs (100 kg) per panel.

• IS10000/Double Diamond and similar Industrial Series = 300 lbs (90 kg) per panel

Closing Speed

Closing speed is measured over a travel distance of 2 or 3 feet. On smaller bi-part doors there may only be

2 feet of movement before the door system enters close-check (latch check). The me measurement should

start once the door has achieved closing speed, usually 6 inches from full open. Mark this point on the oor

with tape or other object. Measure from this point 2 or 3 feet toward the closed posion and mark the next

point. Use a stopwatch to measure the me it takes for the sliding panel to travel this distance during normal

closing cycles. Make sure the door system is not braking or entering close-check during the measurement.

Repeat the measurement 3 mes and use the average value. The allowed me for a sliding panel to cover this

distance during the closing cycle is given in the table below.

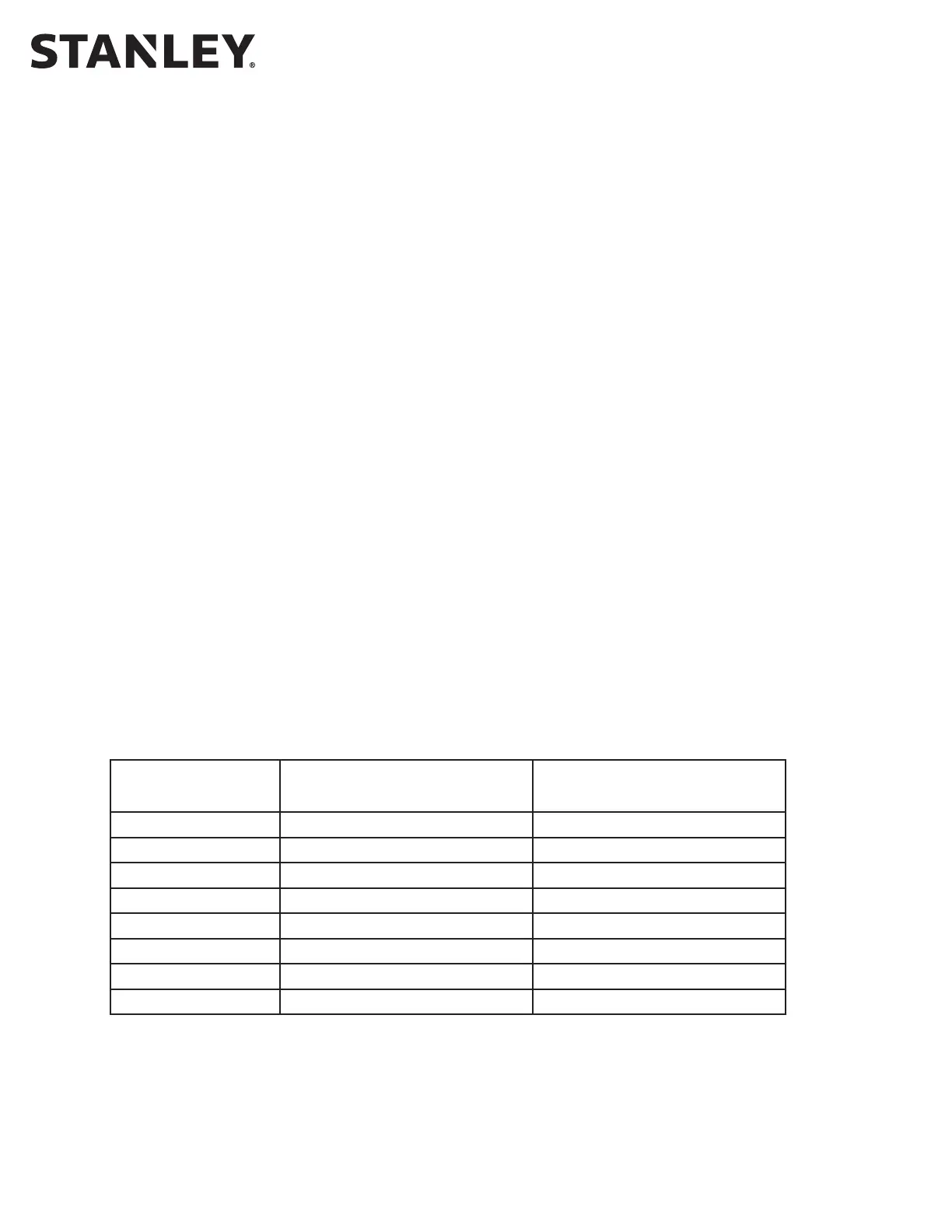

Door Weight

(pounds)

Closing Time (seconds)

2 foot measurement

Closing Time (seconds)

3 foot measurement

160 or less 2.0 3.0

161 to 180 2.1 3.2

181 to 200 2.2 3.3

201 to 220 2.3 3.5

221 to 240 2.4 3.7

241 to 260 2.5 3.8

261 to 280 2.6 4.0

281 to 300 2.7 4.1

Loading...

Loading...