ADJUSTMENTS

– 31 –

1. Gap Adjustment Between Print Head and Platen

1-1. Measuring Gap Between Print Head and Platen

(1) Remove the upper case unit according to procedures

described in chapter 4.

(2) Set the adjustment lever [1] at step two.

(3) Remove the ribbon guide [2].

(4) Insert a thickness gauge [3] between the print head[4]

and the platen [5], and measure the gap.

(5) This measurement must be carried out at the center

[C].

(6) The standard gap value is 0.30 to 0.40 mm.

(7) If the gap does not lie within this range, adjust it by

following the procedure in item 1-2.

Fig. 3-2 Position of Adjustment Lever Fig. 3-3 Gap Measurement

1-2. Adjusting Gap Between Print Head and Platen

If the gap does not lie within the standard range, adjust it by

carrying out the following procedures.

(1) Remove the printer mechanism according to the

procedures described in chapter 4.

(2) Loosen the nut [6].

(3) Insert the shaft in the ø2.5 hole [7].

Adjust the gap by rotating the carriage stay [8] with

the shaft.

When the shaft is lowered to the platen side, the gap

is reduced, and when lowered to the opposite side,

the gap is expanded.

(4) After adjusting, set the adjustment lever [1] to the

position shown in Fig. 3-2 and tighten the nut [6].

(Note) When tightening the nut [6], make sure that the

carriage stay [8] does not move.

Fig. 3-1 Gap Adjustment

Fig. 3-4 Gap Adjustment

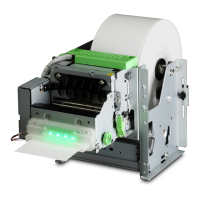

Loading...

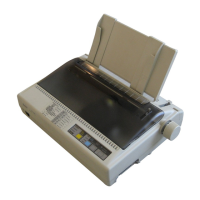

Loading...