Stellar® Heavy-Duty Crane Owner’s Manual

When using the torque data in the chart,

the following rules should be observed:

1. Bolt manufacturer’s particular

specifications should be consulted when

provided.

2. Flat washers of equal strength must be

used.

3. All torque measurements are given in

foot-pounds. To convert to inch-pounds,

multiply by 12.

4. Torque values specified are for bolts with

residual oils or no special lubricants

applied. If special lubricants of high stress

ability, such as Never-Seez compound

graphite and oil, molybdenum disulphite,

colloidal copper or white lead are

applied, multiply the torque values in the

charts by the factor .90. The use of Loctite

does not affect the torque values listed

above.

5. Torque values for socket-head capscrews

are the same as for Grade 8 capscrews.

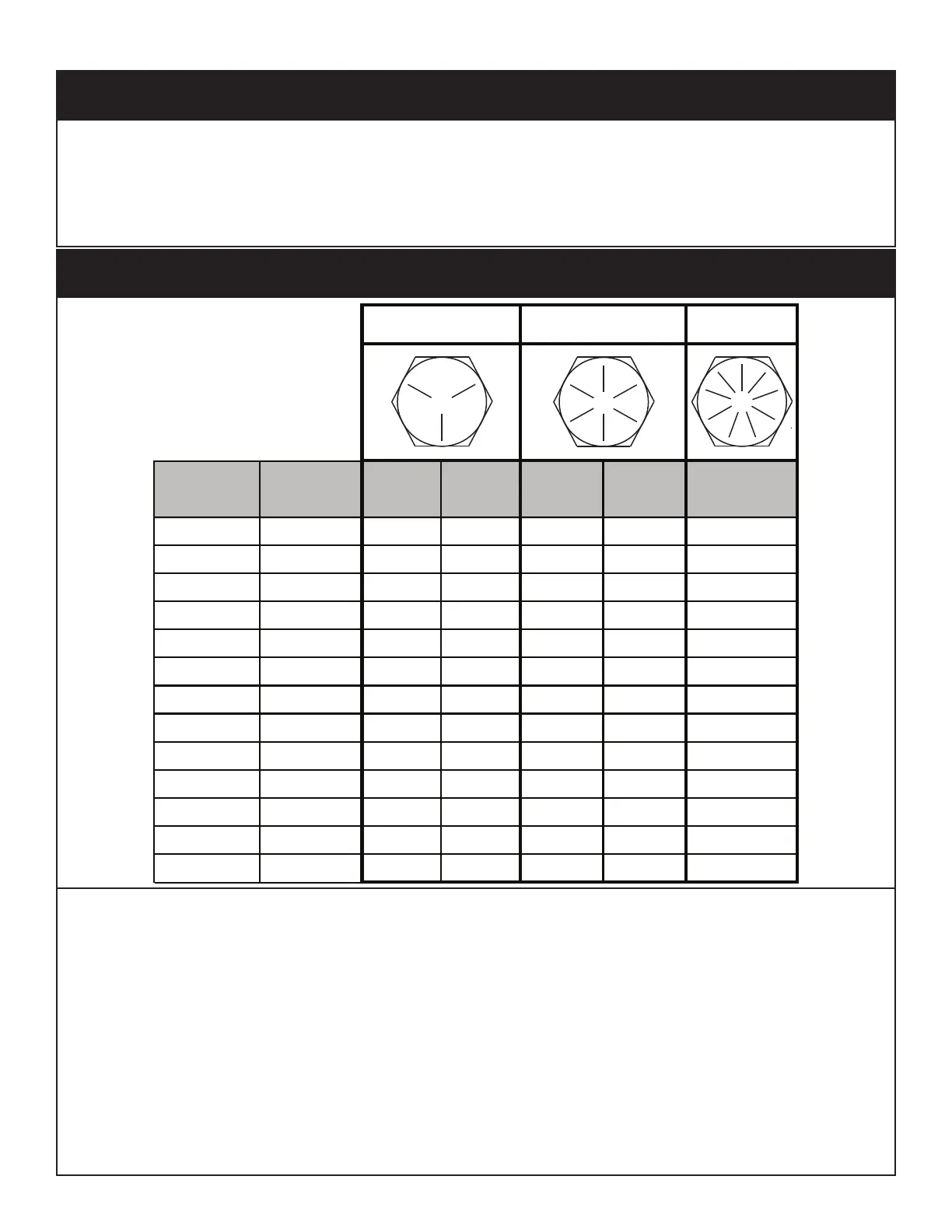

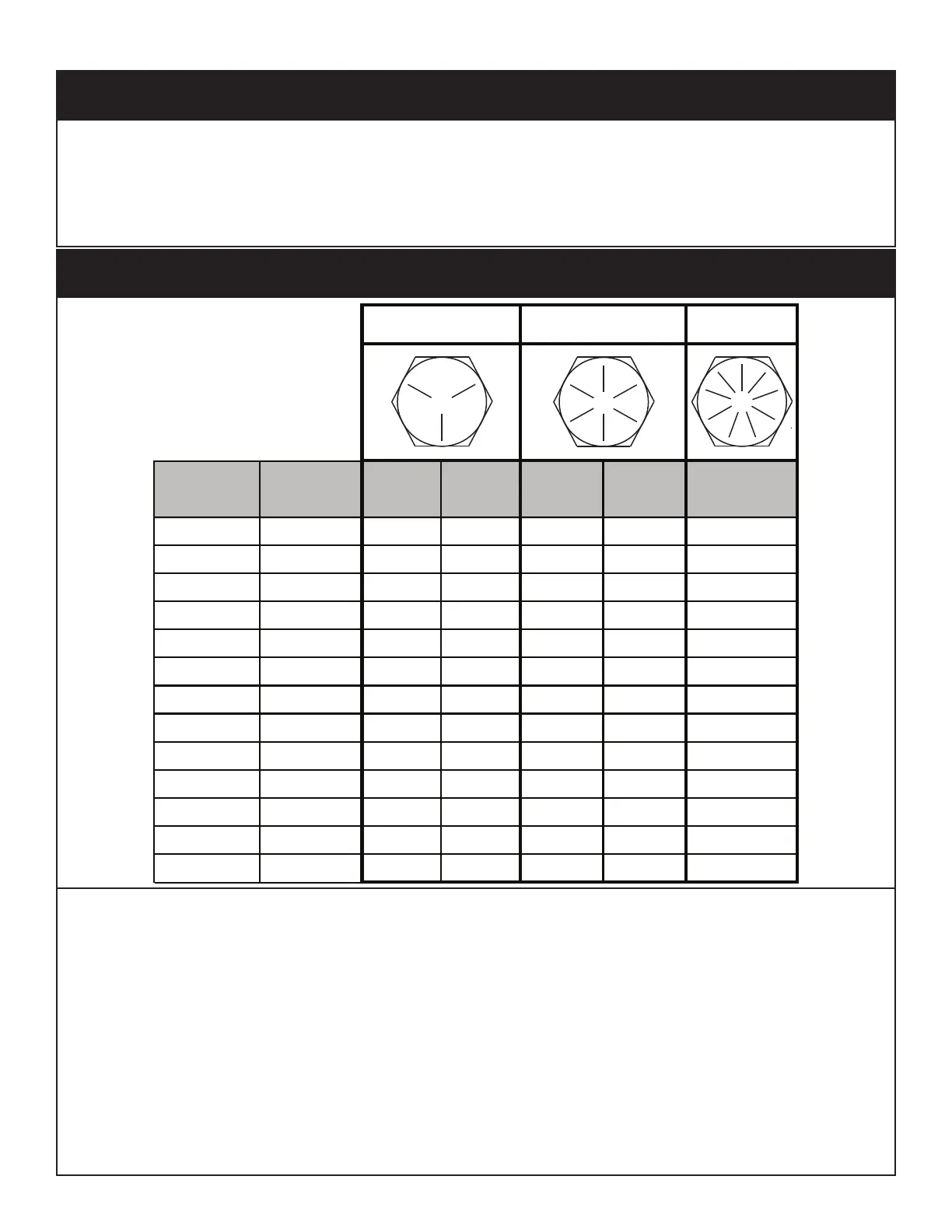

Size Bolt DIA Plain Plated Plain Plated Plated

(DIA-TPI) (Inches) (Ft-Lb) (Ft-Lb) (Ft-Lb) (Ft-Lb) (Ft-Lb)

5/16-18 0.3125 17 13 25 18 22

3/8-16 0.3750 31 23 44 33 39

7/16-14 0.4375 49 37 70 52 63

1/2-13 0.5000 75 57 105 80 96

9/16-12 0.5625 110 82 155115 139

5/8-110.6250 150 115 220 160 192

3/4-10 0.7500 265 200375280340

7/8-9 0.8750 395 295 605 455549

1-8 1.000590445910680823

1 1/8-7 1.1250 795 595 1290 965 1167

1 1/4-7 1.2500 1120 840 1815 1360 1646

1 3/8-6 1.3750 1470 1100 2380 1780 2158

1 1/2-6 1.500 1950 1460 3160 2370 2865

Anytime a gear-bearing bolt is removed, it must be replaced with a new bolt of the

identical grade and size. Once a bolt has been torqued to 75% of its proof load and then

removed, the torque coefficient may no longer be the same as when the bolt was new

thus giving indeterminate damp loads after torquing. Note: Always use Red Loctite

Threadlocker sealant to secure the new bolt.

Gear Bearing Bolt Maintenance

Torque Data Chart

Loading...

Loading...