Stellar® Heavy-Duty Crane Owner’s Manual

Lubrication Recommendations

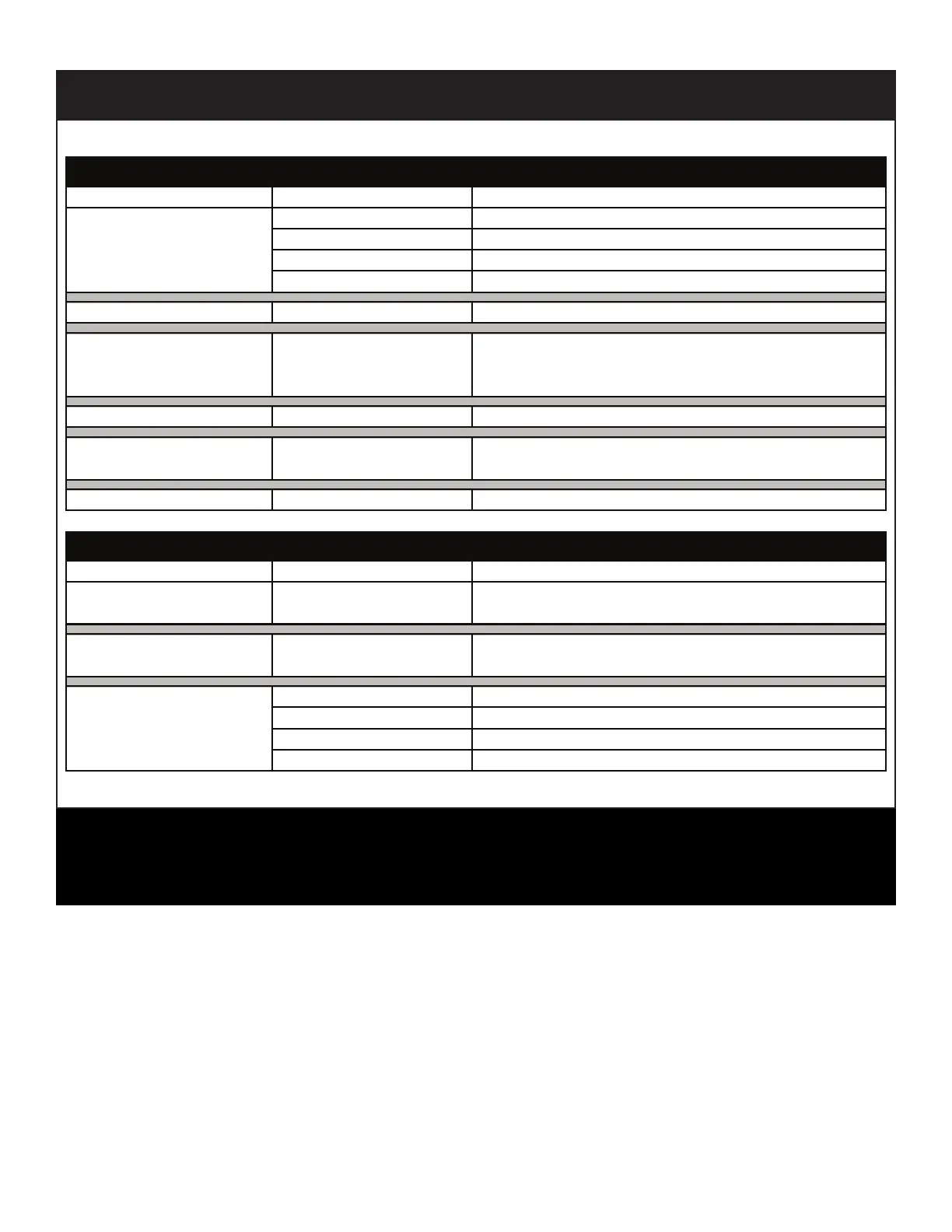

Greasing the Crane

Lubricate all grease gun points with

Extreme Pressure Grease - Stellar P/N: 22059.

Component Location Recommendation

Reservoir

Below –5˚F High VI, low pour, ISO 22, AW hydraulic oil

-5˚F to 90˚F High VI, low pour, ISO 32, AW hydraulic oil

Above 90˚F ISO 46, AW hydraulic oil

Open Gear Teeth Crane Rotation Gear Lithium complex, NLGI 2 grease with moly

Worm Drive Bearings

(including turntable

bearing inner race)

Crane Rotation Gear,

Inside Crane

Compartment

Lithium complex, synthetic based NLGI 00 grease

Cylinders Crane Pivot Areas Lithium complex, NLGI 2 grease

Synthetic 80W-90 gear oil with friction modifiers, API

GL-5

Wear Pad Lubrication Extension Booms Synthetic lubricant containing Teflon®

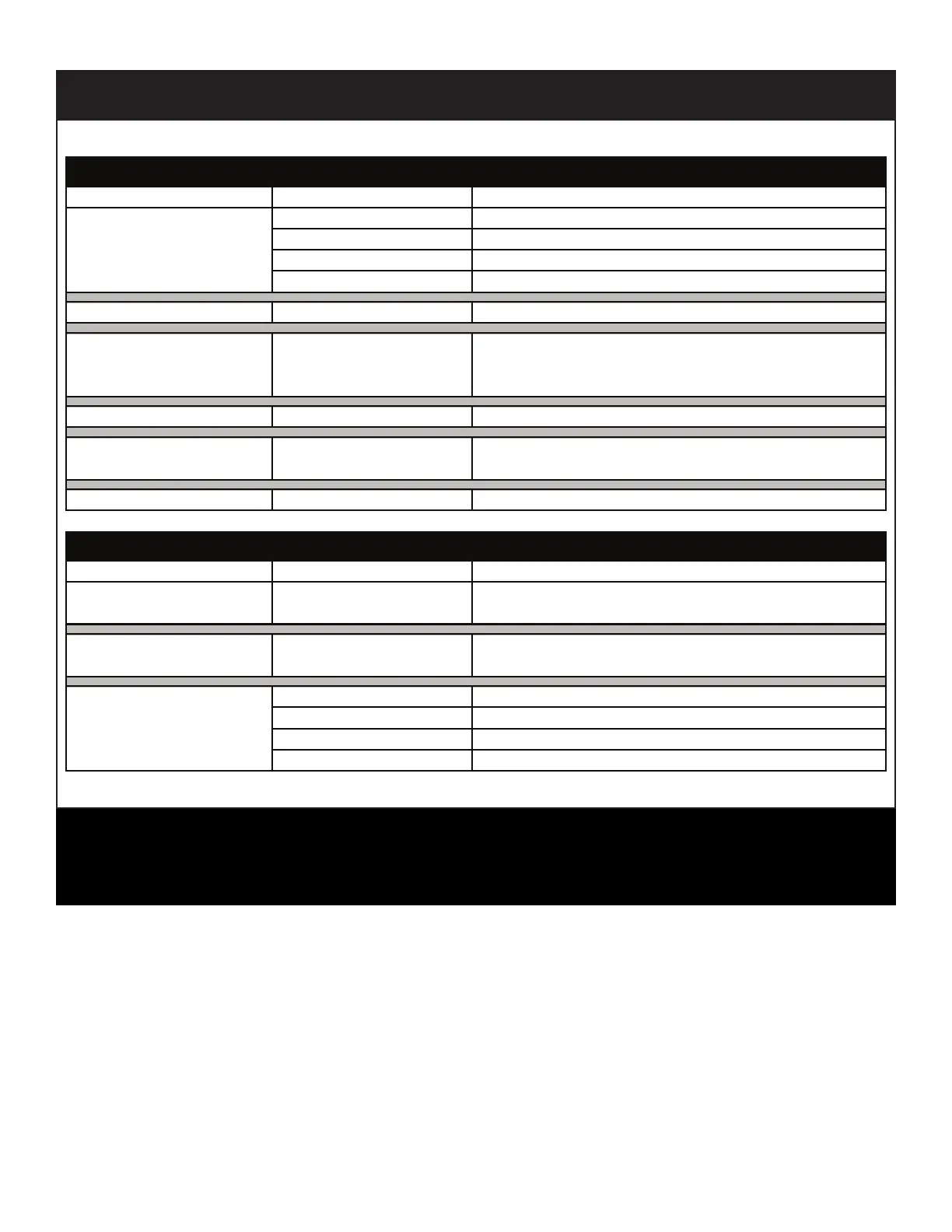

Component Location Recommendation

Reciprocating Single

Stage

Compressor Crankcase ISO 100 compresser oil

Reciprocating Double

Stage

Compressor Crankcase ISO 100 compresser oil

Compressor Crankcase

-15˚F to 86˚F Synthetic performing ISO 32 compresser oil

-23˚F to 100˚F Synthetic performing ISO 46 compresser oil

32˚F to 113˚F Synthetic performing ISO 68 compresser oil

Loading...

Loading...