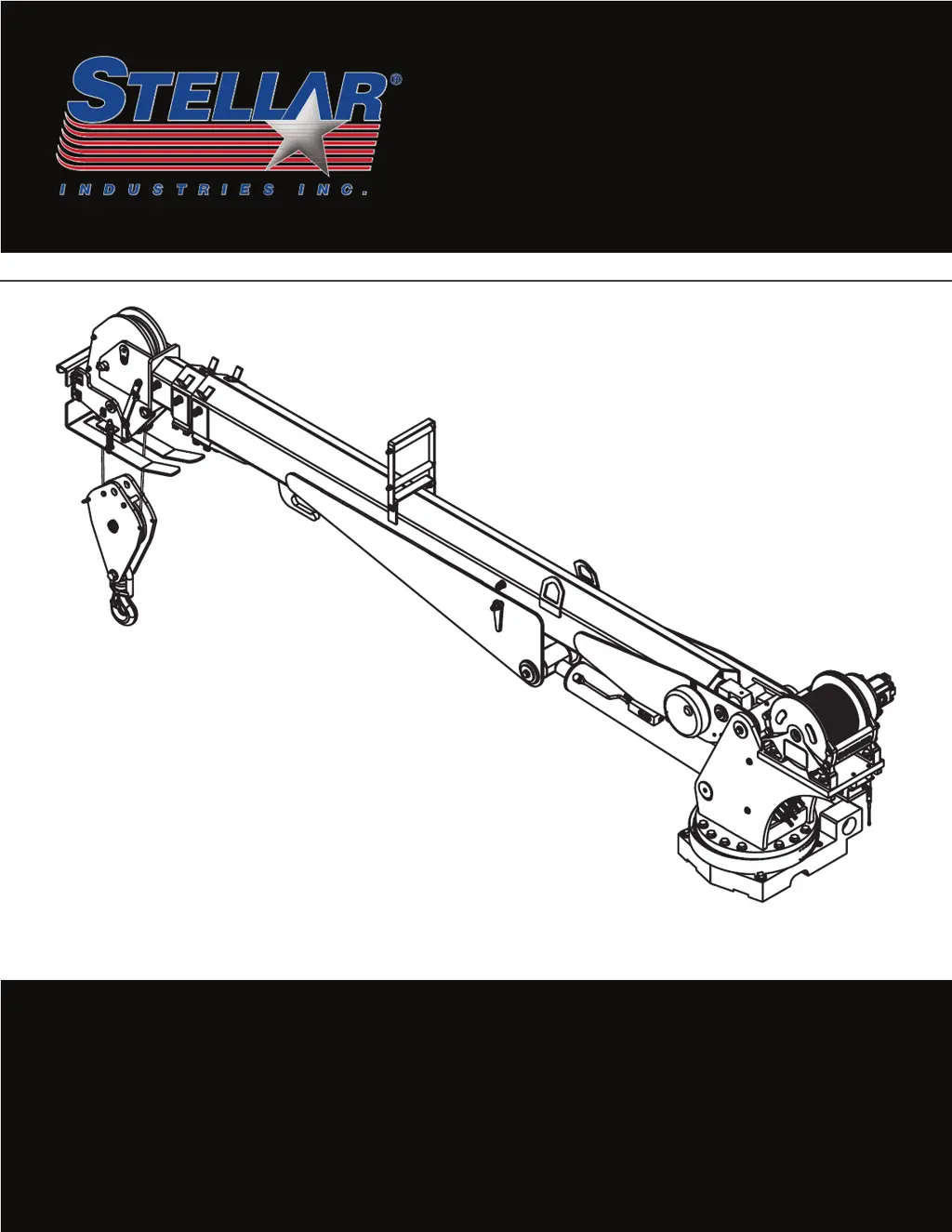

How to troubleshoot a stellar labs 12621 Construction Equipment crane that won't operate?

- JJared LeAug 18, 2025

If your Stellar Labs Construction Equipment crane isn't operating, there are several things to check: * Ensure the parking brake is engaged. * Ensure the PTO is engaged. * Confirm there's 12V power going to the radio receiver; if not, trace back to the power source, checking for blown fuses or loose ground connections. * Verify the transmitter batteries are fully charged. * Check that the hydraulic pump is operating at its rated flow (GPMs) using a flow meter; a weak pump may require contacting Stellar Customer Service.